Maintenance device for rail plate production adopting unit assembly-line method, and assembly-line unit

A track slab and flowing water technology, which is applied in the field of rail transportation, can solve problems such as difficulty in adapting to the high-efficiency operation of track slabs, difficulty in ensuring product quality, and low work efficiency, and achieve the effects of improving maintenance efficiency, good product quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

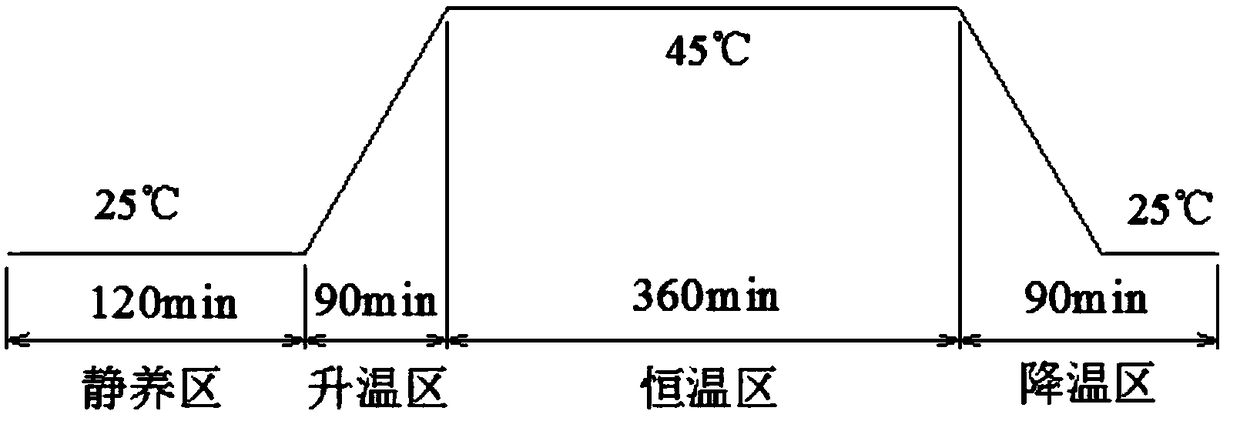

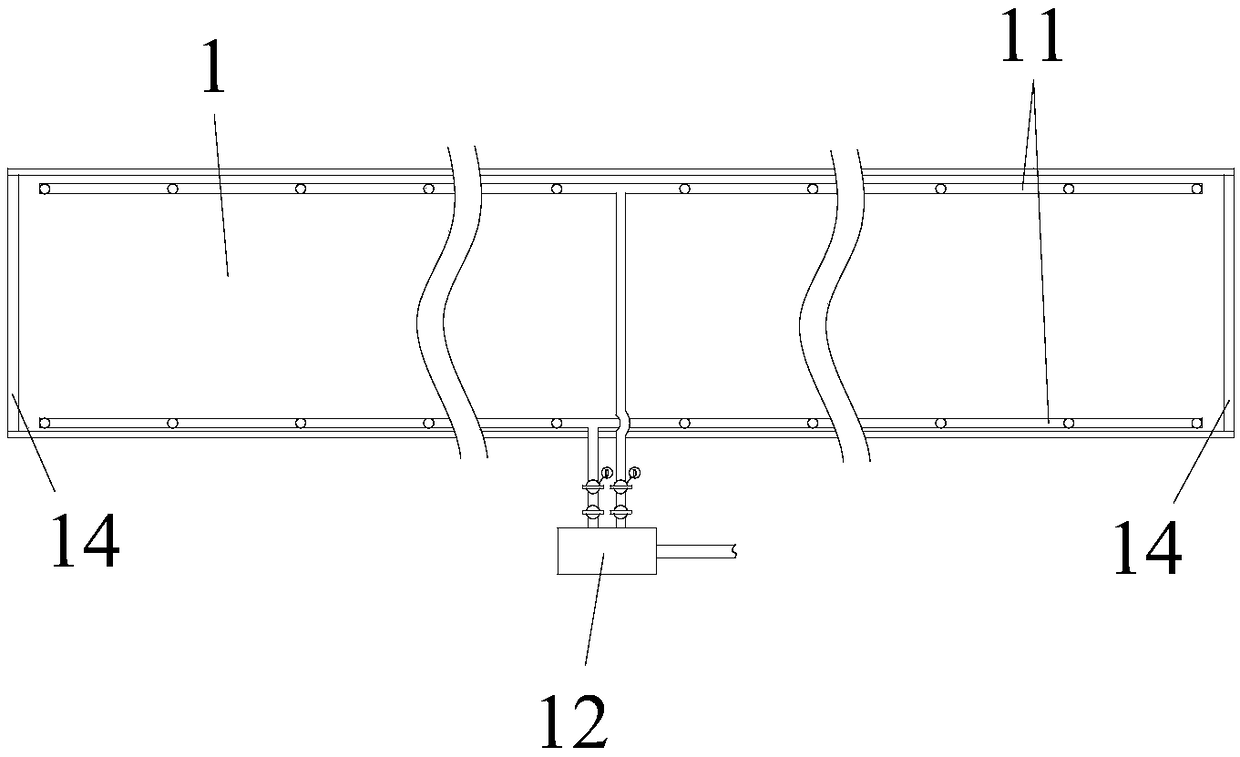

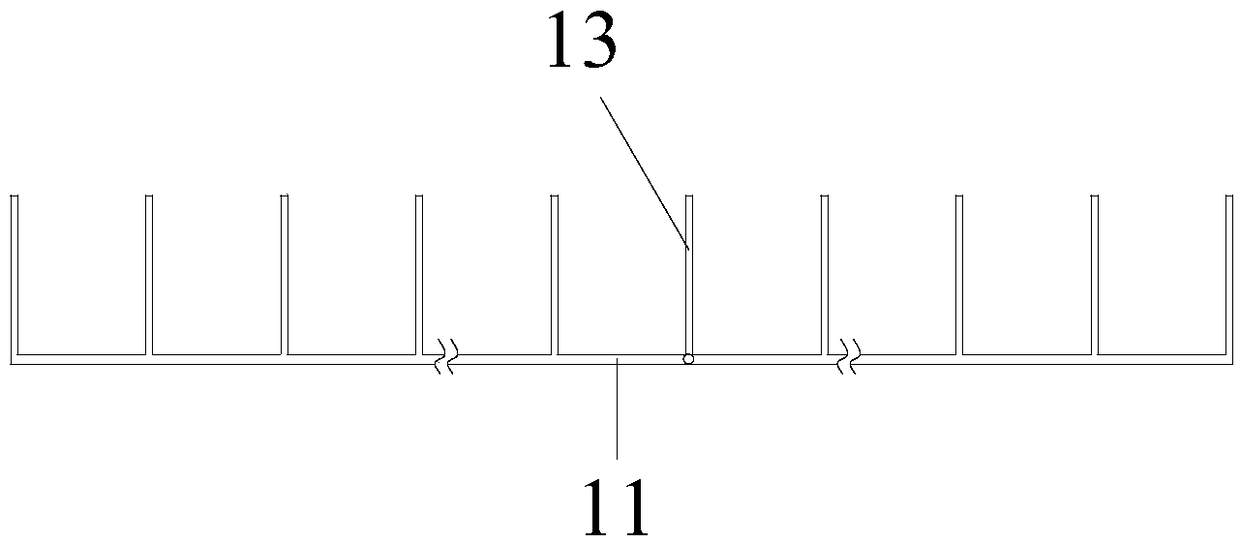

[0045] Such as Figure 2-3 As shown, a maintenance device for the production of track slabs by the flow method of the unit according to the present invention includes at least one maintenance channel 1, and the maintenance channel 1 is a rectangular parallelepiped pipeline. Arranged in parallel, the maintenance channel 1 is provided with a guide rail, and the guide rail is used for the movement of the track plate mold 2 in the maintenance channel 1 .

[0046] Both ends of the maintenance passage 1 are provided with gates 14, the maintenance passage 1 is provided with a steam pipe and a temperature sensor, the maintenance passage 1 is provided with cooling components, and the steam pipe is provided with several outlets, so The steam pipeline communicates with a steam generator, and the steam generator is connected with a control component, and the control component is connected with the temperature sensor and the cooling component, and the control component is an industrial com...

Embodiment 2

[0051] Such as Figure 4 Shown, a kind of assembly line of the present invention comprises:

[0052] The track slab mold 2 is used to set the ballastless track slab structure including the reinforcement cage and the prestressed steel bar, and cast the track slab inside it, and the two ends of the prestressed steel bar are respectively screwed to the tension rods, and the tension bars The pull rod extends out of the wall of the track plate mold 2;

[0053] The tensioning device 3 is adapted to the tension rod, and is used for prestressing the prestressed steel bars;

[0054] pouring device, for pouring concrete into the track slab mold 2;

[0055] A vibrating device for vibrating the concrete in the poured track slab mold 2;

[0056] At least one maintenance device as described in any one of the above, used for maintenance of the track slab in the track slab mold 2 after vibration;

[0057] The stretching device 4 is adapted to the tension rod and can rotate the tension rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com