Fingerprint imaging module and formation method thereof, fingerprint imaging module motherboard, and electronic equipment

An imaging module and fingerprint technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve the problems of large module thickness, difficulty in improving integration, and reduce adoption, benefit cost control, and reduce module size. The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] It can be seen from the background art that the fingerprint imaging module in the prior art has the problem of excessive thickness of the module. Combining with the structure of a fingerprint imaging module, the reason for the excessive thickness of the module is analyzed:

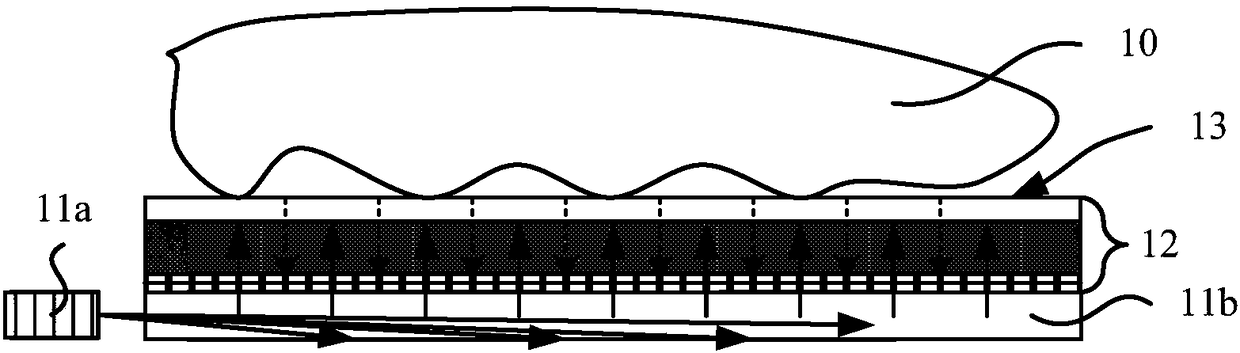

[0052] The optical fingerprint imaging module mainly includes: protective cover, optical sensor, integrated chip (IC), flexible circuit board (FPC) and electronic devices on the flexible circuit board (including light source LED), light guide plate, upper protective shell and Lower protective shell and other main components. Among them, the optical sensor is made on a glass substrate using semiconductor technology such as amorphous silicon thin film transistor (a-Si TFT), low temperature polysilicon thin film transistor (LTPS TFT) or oxide semiconductor thin film transistor (OS TFT); after cutting , dispensing, bonding and other processes to achieve packaging.

[0053] refer to figure 1 , shows a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com