Glass tube coating device

A technology of coating device and glass tube, which is applied to the device and coating of surface coating liquid, can solve the problems of inapplicability to large-scale automatic production, low degree of automation, labor, etc., and achieve large-scale automatic production and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

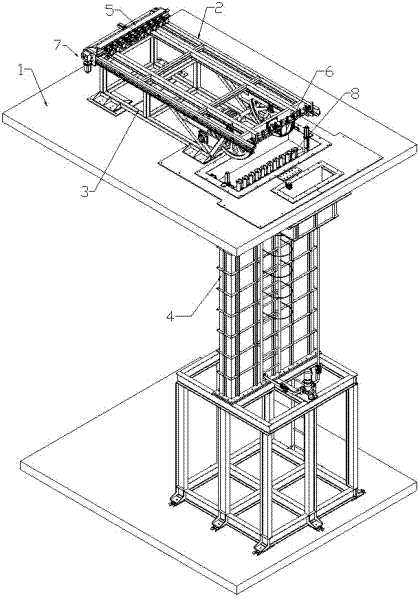

[0022] With reference to the drawings, the present invention proposes a glass tube coating device, including a frame 1, on which:

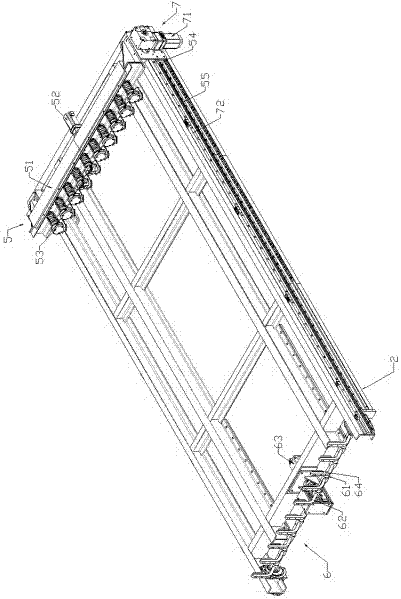

[0023] Glass shelf 2;

[0024] The locking mechanism 5 is slidably arranged on the glass placing frame 2 to firmly fix the glass tube;

[0025] Turning mechanism 3 drives the entire glass placement rack 2 to turn 90°;

[0026] The lifting mechanism 7 drives the locking mechanism 5 to move on the glass placing frame 2;

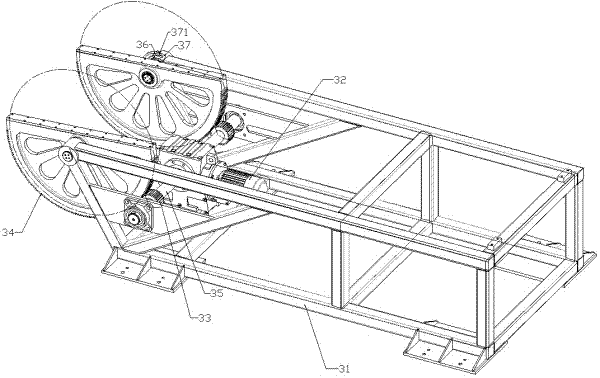

[0027] Specifically, the reversing mechanism 3 includes a bracket 31, a reversing motor 32, a driving gear 33, and a driven gear 34. The driving gear 33 and the driven gear 34 mesh with each other. The driven gear 34 is a semicircular gear with a semicircular shape. The center of the shaped gear is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com