A kind of composite damping foam rubber material and preparation method thereof

A foam rubber and composite damping technology, applied in the field of rubber materials, can solve problems such as poor sound absorption performance, and achieve the effects of improved sound absorption, environmental friendliness, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

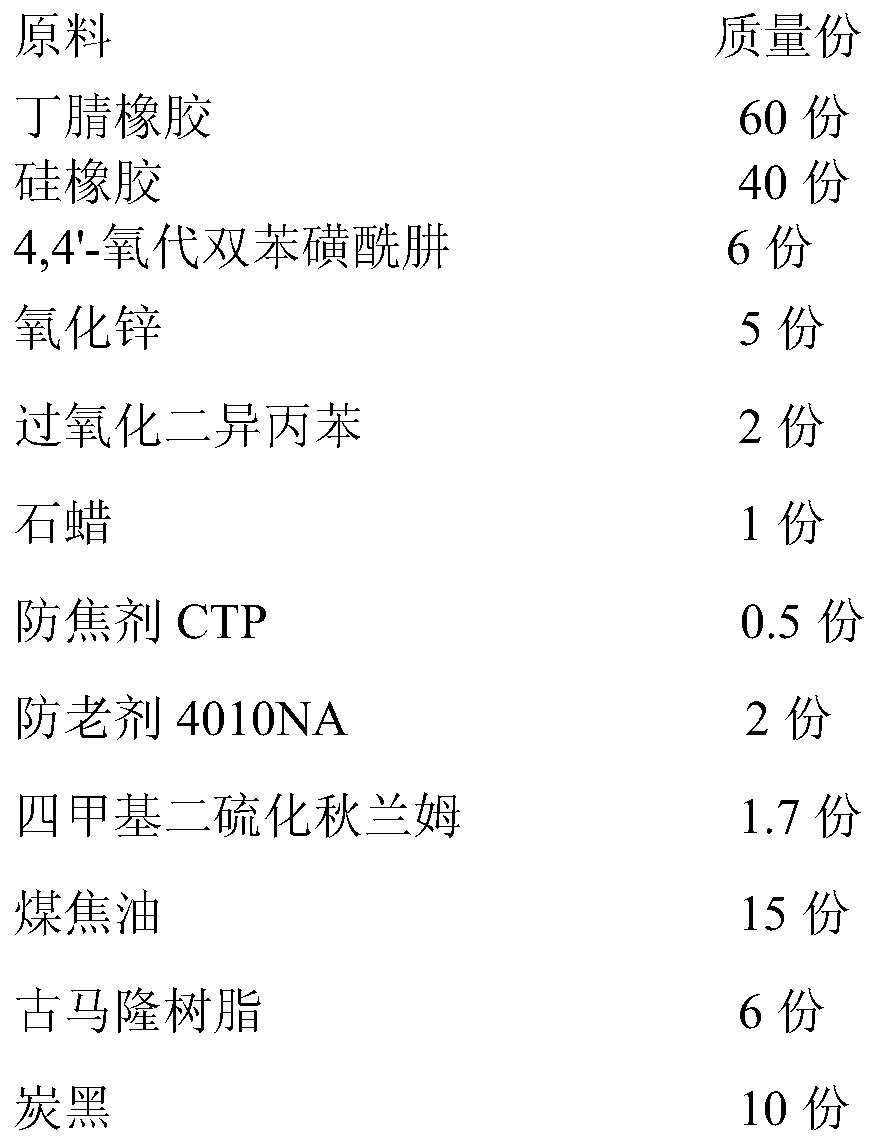

[0062] A rubber material for noise reduction of a transformer body. The rubber material is made of the following components in proportion by mass:

[0063]

[0064] The preparation of above-mentioned composite damping foam rubber comprises the following steps:

[0065] a. Weigh each component according to the above formula, and set aside;

[0066] b. At a temperature of 60°C, masticate 60 parts of nitrile rubber for 2 minutes on an open mill;

[0067] c. At a temperature of 60°C, add 40 parts of silicone rubber to the open mill, and blend with nitrile rubber for 4 minutes;

[0068] d. At a temperature of 60°C, add 5 parts of zinc oxide, 0.5 parts of anti-scorch agent CTP, and 2 parts of anti-aging agent 4010NA to the open mill and blend for 2 minutes;

[0069] e. At a temperature of 60°C, add 60 parts of carbon black, 1 part of paraffin, 15 parts of coal tar, and 6 parts of coumarone resin to the open mill and blend for 4 minutes;

[0070] f. Add 2 parts of dicumyl perox...

Embodiment 2

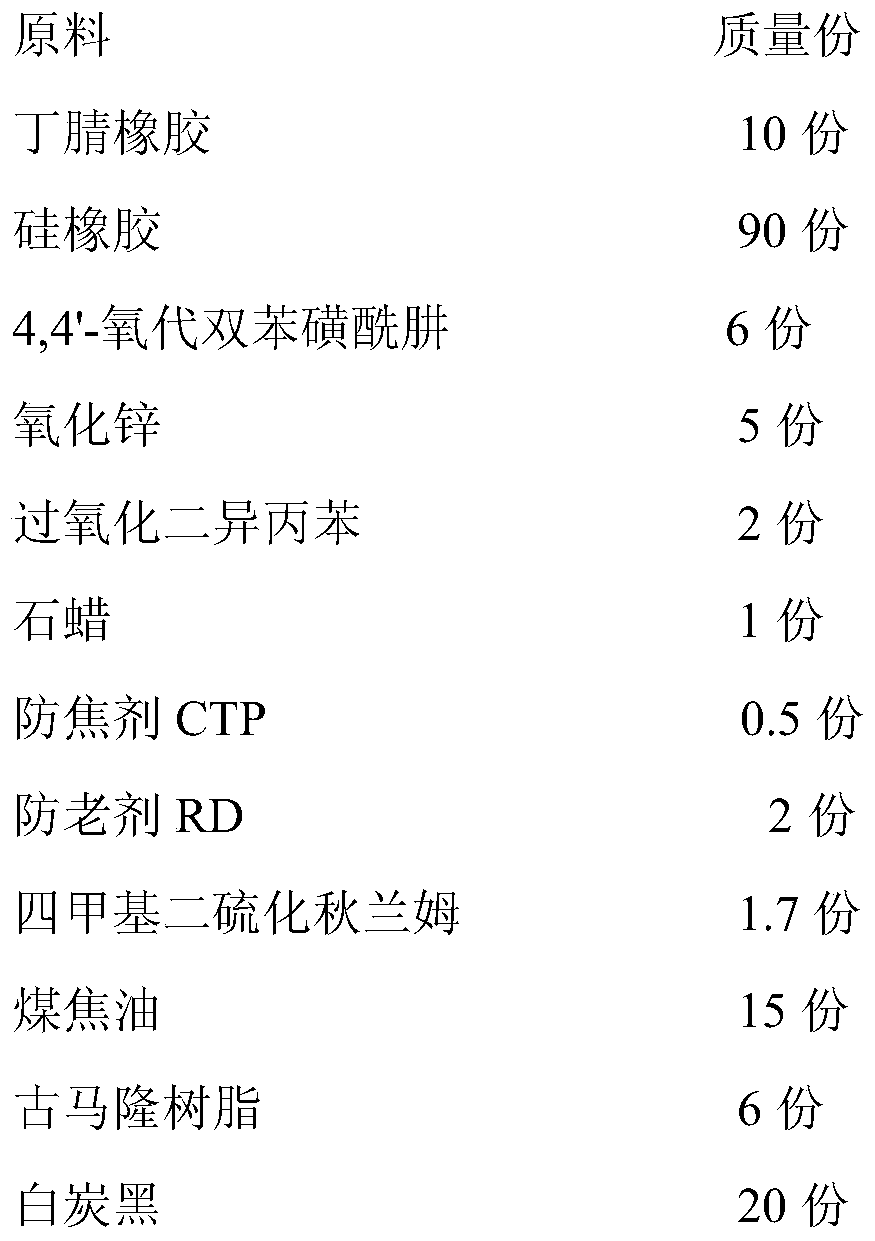

[0074] A rubber material for noise reduction of a transformer body. The rubber material is made of the following components in proportion by mass:

[0075]

[0076] The preparation method of the composite damping foam rubber is as described in Example 1.

Embodiment 3

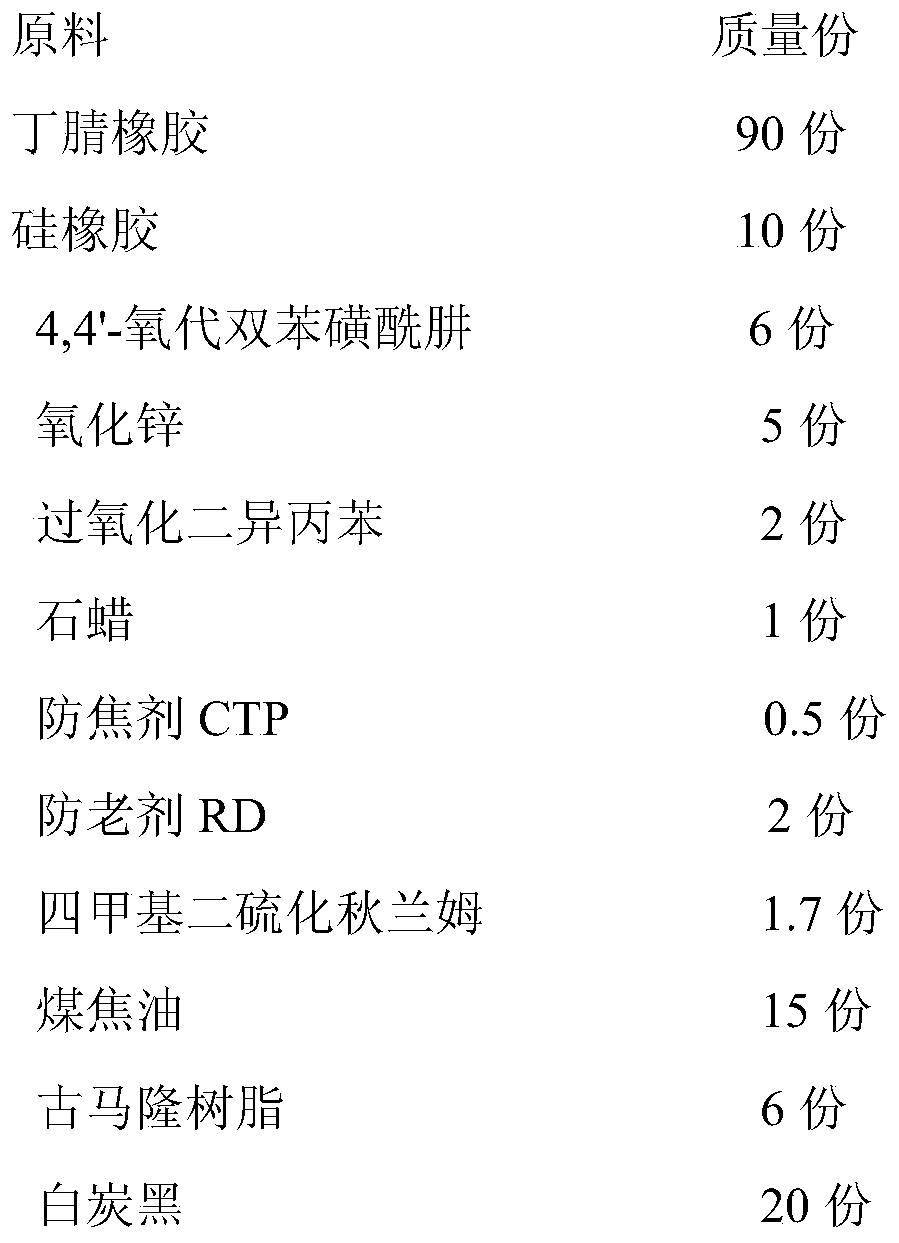

[0078] A rubber material for noise reduction of a transformer body. The rubber material is made of the following components in proportion by mass:

[0079]

[0080] The preparation method of the composite damping foam rubber is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com