Production process of low-formaldehyde vehicle urea

A technology for vehicle urea and production process, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing production efficiency, wasting stirring time, improving urea raw materials, etc., and improving stability and efficiency. The effect of reducing the probability of oxidation and saving the time of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

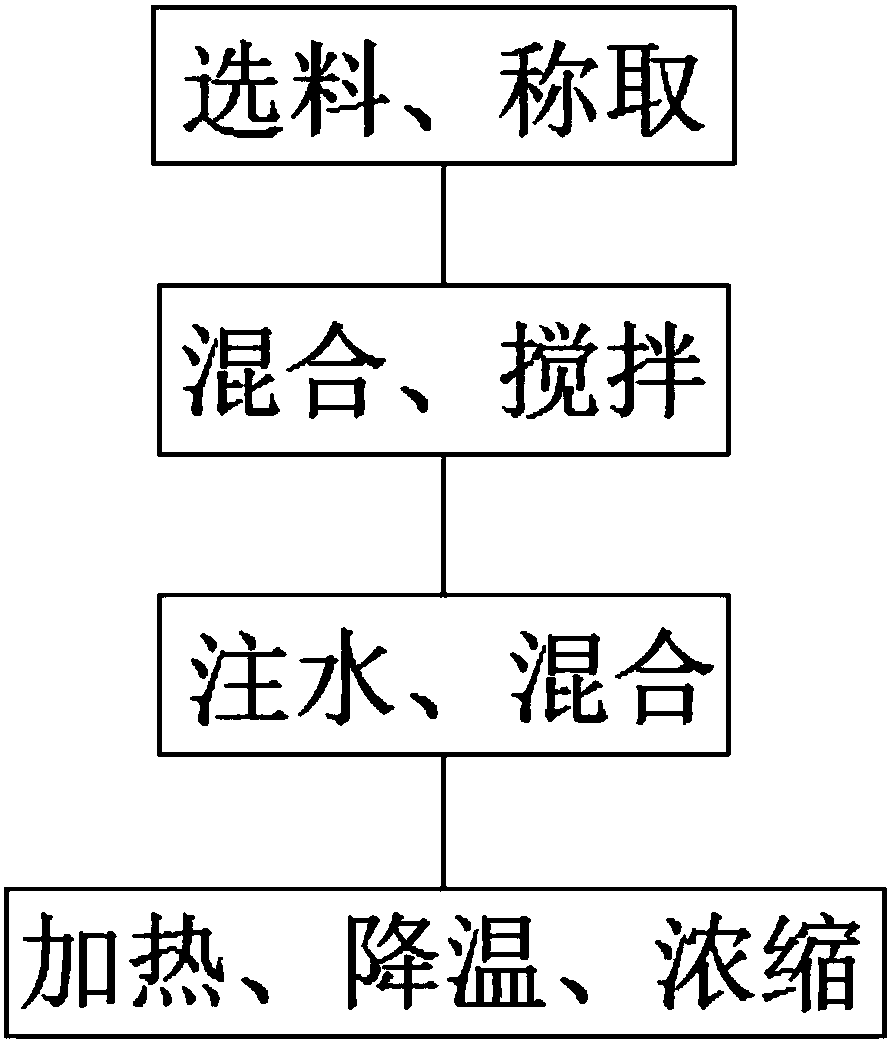

[0023] see figure 1 , the present invention provides a technical solution: a production process of low-formaldehyde vehicle urea, comprising the following steps:

[0024] a. First select the urea raw material, then classify the selected raw material, and then put it on the electronic scale to weigh one by one;

[0025] b. After step a is completed, pour the weighed raw materials into the mixer, and then use the agitator to stir the mixed raw materials;

[0026] c. After step b is completed, inject pure water into the mixer to mix with the mixed raw materials to form a urea solution;

[0027] d. After step c is completed, concentrate the urea liquid, including heating and cooling.

[0028] The electronic scale adopts a high-precision electronic scale, and before using the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com