Technology for producing ultra-high strong fiber anti-cutting gloves

A manufacturing process and ultra-high-strength technology, applied in fiber type, fiber treatment, knitting, etc., can solve problems such as difficult large-scale, automated production process, low production efficiency, heavy gloves, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

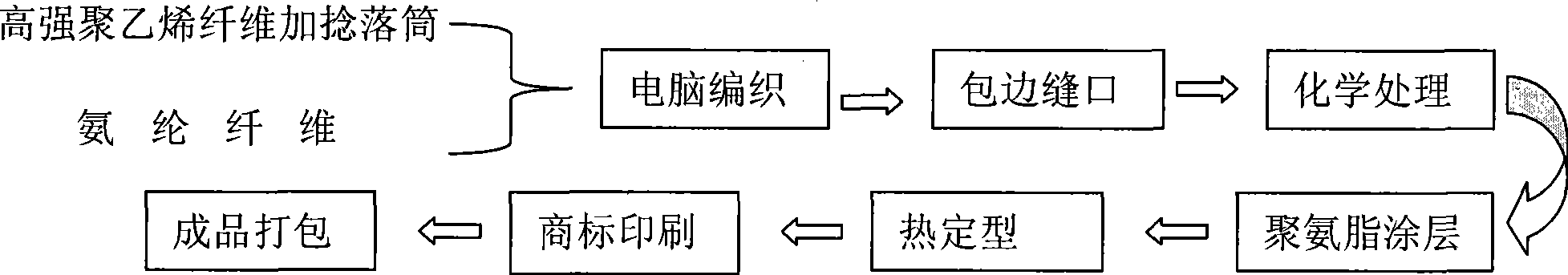

[0014] see figure 1 :

[0015] (1) Firstly, super strong polyethylene fiber with a flexible chain of 400D×160F and a strength range of 36g / D-40g / D is used as the basic raw material. Super strong polyethylene fiber is one of the three high-performance fibers in the world today (carbon fiber, aramid fiber , super-strength polyethylene), it is one of the three high-performance fibers with the highest strength, 15 times that of high-quality steel wire, and the smallest density, wear-resistant, and most chemical-resistant fiber. As a basic material for cut-resistant gloves.

[0016] (2) After twisting 30-50 pieces / m of super-strength polyethylene fiber, it is packed into a tube.

[0017] (3) Use a computerized high-speed glove knitting machine with a needle pitch of 13 needles or 15 needles for knitting. When knitting, the fingers are all woven with the above-mentioned super-strength polyethylene fiber; the front half of the palm and the corresponding back of the hand are also al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com