Three-dimensional housing of automobile trunk

A back door, three-dimensional technology, applied in vehicle parts, superstructure, superstructure sub-assemblies and other directions, can solve the problems of low processing cost, difficult to achieve impact resistance, high permeability, and achieve low processing cost and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

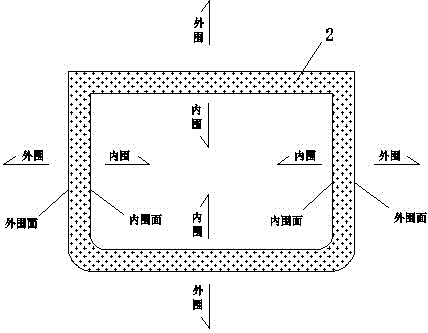

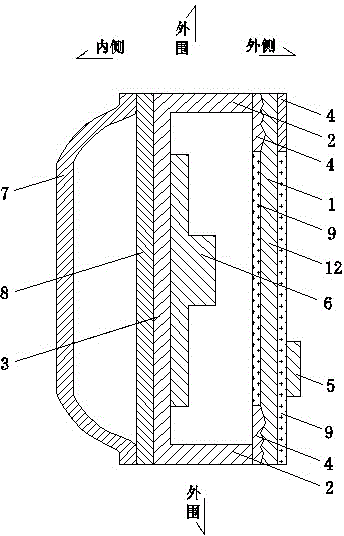

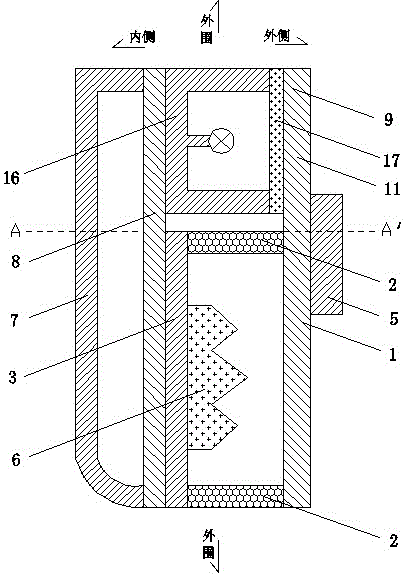

[0075] Such as figure 2 Shown embodiment 1 of the three-dimensional casing for the extended car tailgate of the present invention includes a casing, an outer transparent box body, a three-dimensional decoration 6 and an outer insert 5;

[0076] The shell is composed of an inner shell 7 and an outer shell 8. The inner shell 7 and the outer shell 8 are plate-shaped materials. The inner shell 7 is arranged on the inner side of the outer shell 8. The inner shell 7 and the outer shell 8 are hollow structures whose edges are connected to each other and the middle part is kept at a certain distance;

[0077] The outer transparent box body is located on the outside of the outer shell 8. The outer transparent box body is a hollow box body whose outer direction is transparent. The outer transparent box body includes an outer transparent material layer 1, several frames 2, an inner shell 3, an outer The interconnection of the transparent material layer 1, the frame 2, and the inner shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com