Water flow control system

A water flow control and water flow technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of water consumption, time consumption, and shortened service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

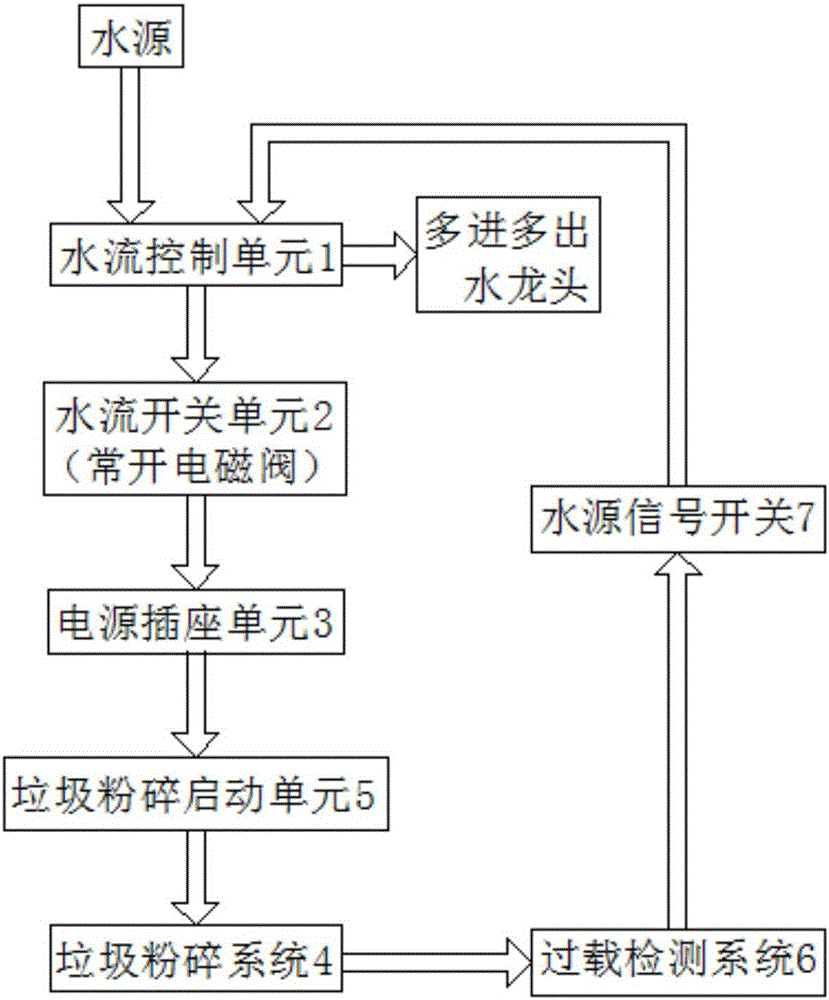

[0021] like figure 1 As shown, a water flow control system includes a water flow control unit 1, and the water flow control unit 1 adopts a faucet, wherein the faucet adopts multi-input and multiple-outlet (for example: a dual-temperature water outlet faucet, two of which are dual-temperature water outlets, One of them is a dedicated control device of the water flow control unit 1);

[0022] The water flow switch unit 2 controls the power socket unit 3 and the main power supply to be powered on and off, wherein the water flow switch unit 2 adopts a normally open solenoid valve, and when the water flow in the pipeline is directional, the contact of the solenoid valve is touched to make it closed, and then Connecting the water flow switch unit 2 means that the power socket unit 3 and the main power supply are energized; when the water flow stops, the water flow thrust disappears, so the water flow switch unit 2 (normally open solenoid valve) resets and powers off, realizing the ...

specific Embodiment approach 2

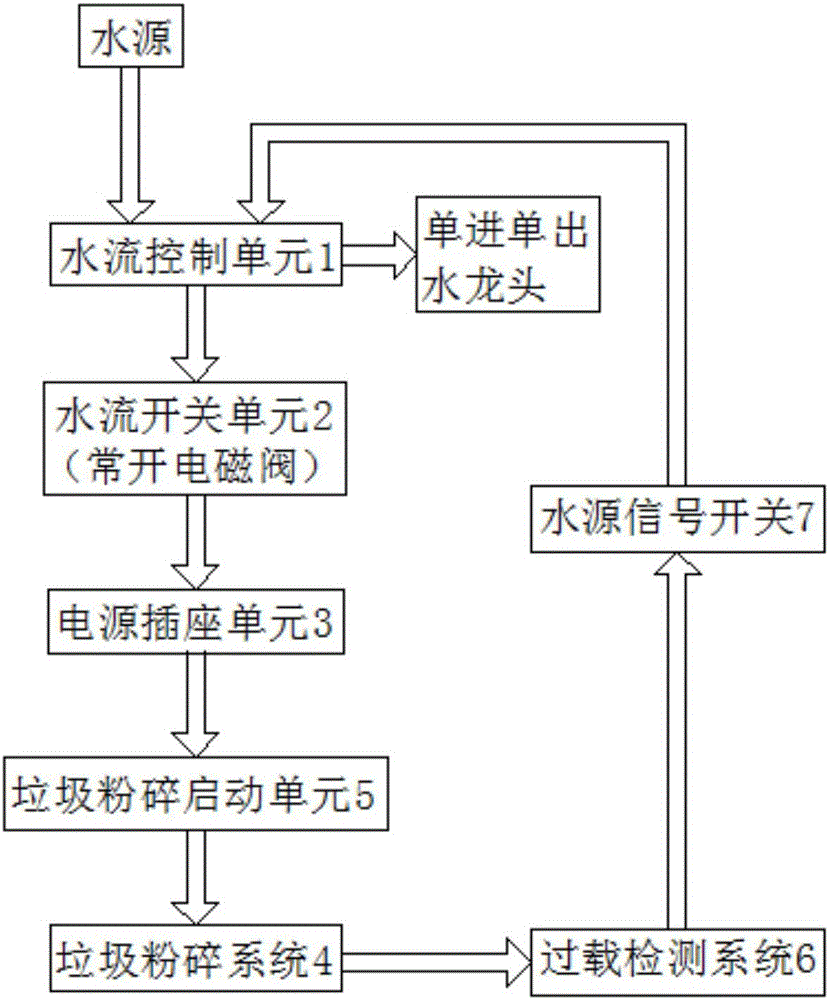

[0028] like figure 2 As shown, the water flow control unit 1 also includes a single-inlet and single-outlet faucet, which is used as a dedicated control device for the water flow control unit 1 .

[0029] The rest are as in the first embodiment, which will not be repeated here.

[0030] When the control system is started, the water flow control unit 1 (faucet) can be turned on, and the water flow force can make the water flow switch unit 2 (normally open solenoid valve) close, and then the power socket unit 3 and the main power supply can be automatically energized; The conductor makes the main body of the power socket unit 3 conductive, and then the garbage shredding starting unit 5 activates the garbage shredding system 4, so as to clean up the garbage.

[0031] When the garbage cleaning work is overloaded, the overload detection system 6 is started, and then the water flow control unit 1 (water tap) is closed through the water source signal switch 7 . Because the water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com