Carrier roller pneumatic rubber scraping device of belt conveyor

A technology of belt conveyor and scraping device, which is applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of reducing production efficiency, conveyor belt deviation, equipment shutdown, etc., to achieve fully automatic work, Stable and reliable scraping, reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

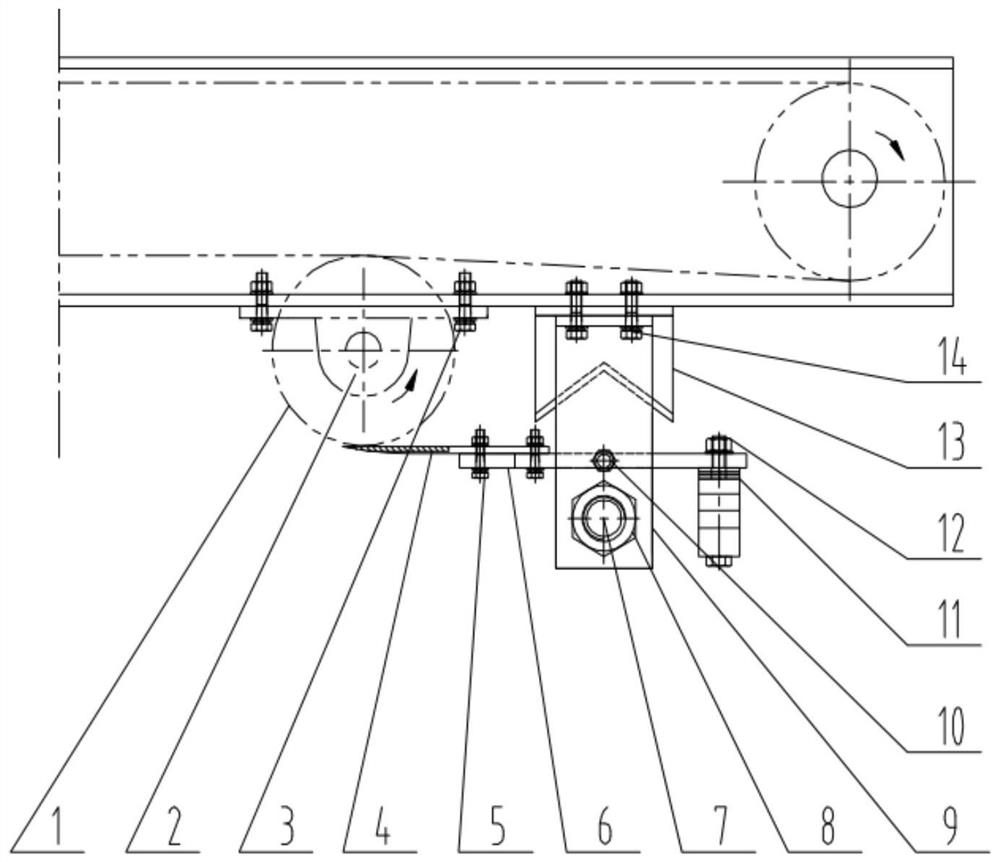

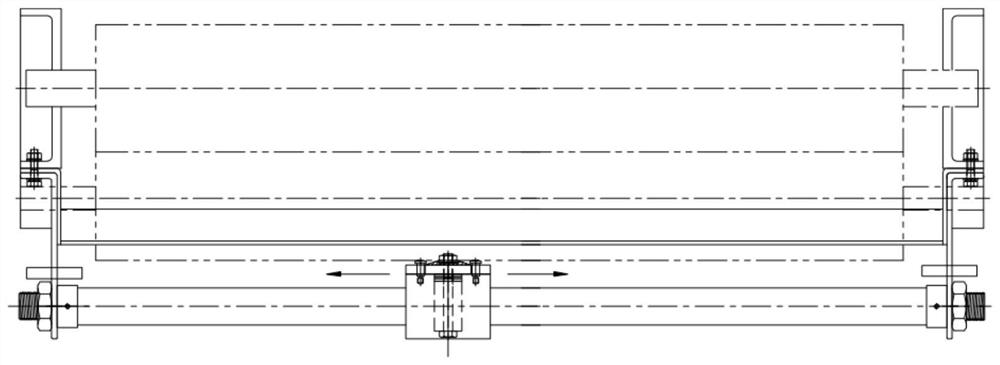

[0015] combine figure 1 , figure 2 As shown, a pneumatic scraping device for rollers of belt conveyors includes rollers 1, bearings with seats 2, 1# bolts 3, scrapers 4, 2# bolts 5, scraper seats 6, rodless cylinders 7, connecting Nut 8, cylinder support 9, proximity switch 10, counterweight 11, 3# bolt 12, rubber baffle plate 13, 4# bolt 14. The shaft heads at both ends of the idler roller 1 are installed on the bearing with seat 2, the bearing with seat 2 is fixed on the frame of the belt conveyor through the 1# bolt 3, the scraper 4 is fixed on the scraper seat 6 through the 2# bolt 5, and the scraper The seat 6 is fixed on the slider of the rodless cylinder 7 with screws, the counterweight 11 is connected with the scraper seat 6 through the 3# bolt 12, the two ends of the rodless cylinder 7 are installed on the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com