Full-automatic sheet strip sewing machine and control method

A control method and sewing machine technology, applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve problems such as time-consuming and laborious, cumbersome processes, and difficult coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

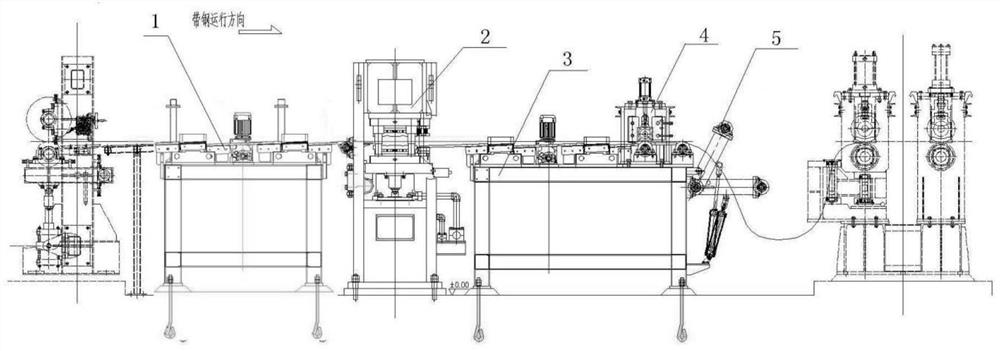

[0042] The sewing machine of this embodiment is provided with a sewing machine body 2, and the two sides of the sewing machine body 2 are respectively provided with a centering platform a1 and a centering platform b3, and one side of the centering platform b3 is connected with the sewing machine body 2, and the centering platform b3 The other side is connected with the pinch roller device 4 , and a pressure roller device 5 is arranged on the side of the pinch roller device 4 .

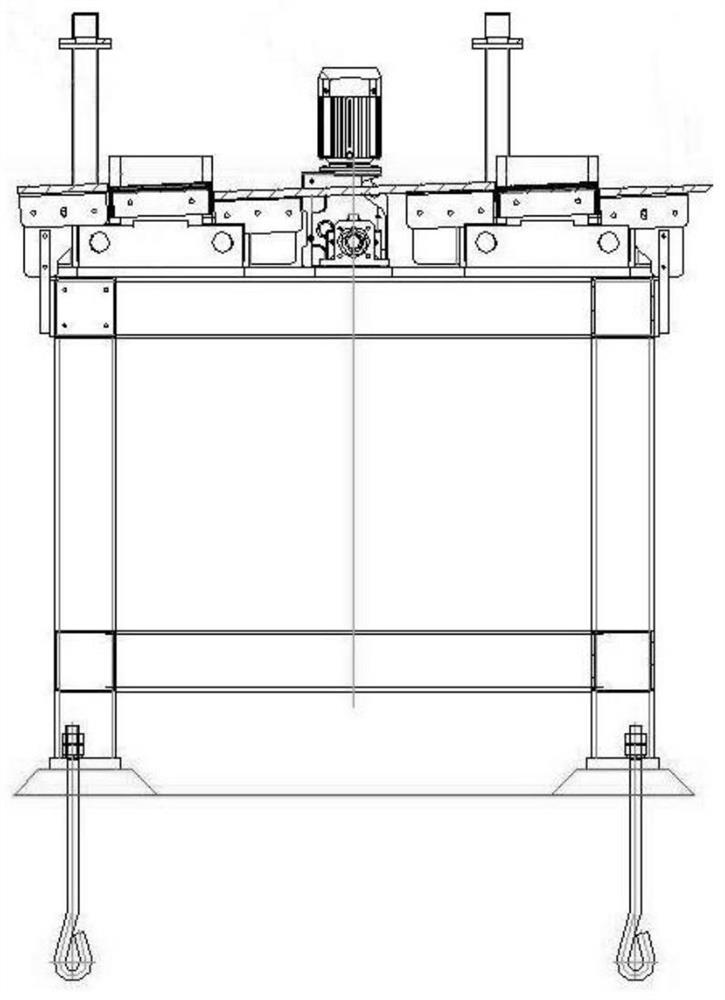

[0043] Wherein, the sewing machine body 2 is provided with a frame 15, an operation box 10 is provided in the frame 15, an operation console is provided below the operation cabinet 10, a descending hydraulic cylinder 20 is arranged in the console, and the top of the descending hydraulic cylinder 20 passes through the hydraulic cylinder. Joint 19 links to each other with dynamic platen 11, is also provided with rising hydraulic cylinder 18 below dynamic platen 11, is provided with idler roller 17 above m...

Embodiment 2

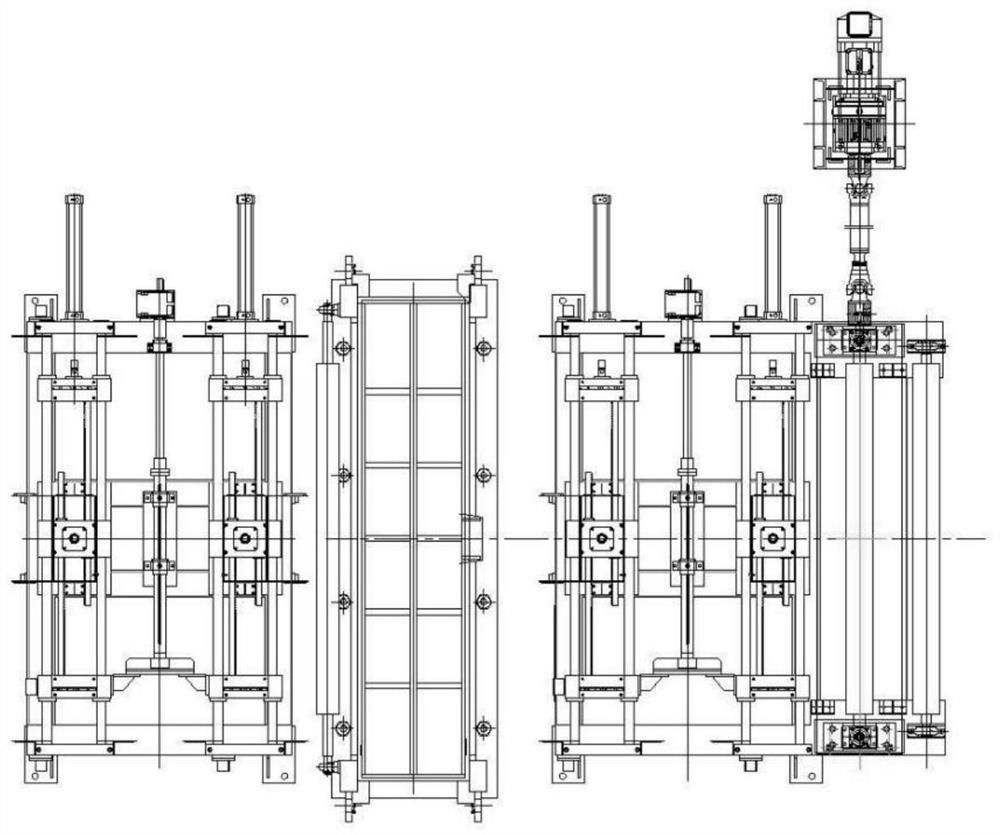

[0051] Guide plate platform 33 is installed on the movable frame 41, and movable frame 41 is connected on the platform 37 by linear guide rail 40, and splint device 38 is installed on the movable frame 41, and cylinder 35 is housed in the back of splint device 38, is used for driving splint device 38 actions, The detection switch 34 is installed before the splint device 38, and the ball screw 39 is installed on the moving frame 41. The ball screw 39 is connected to the variable frequency reduction motor 36 with the encoder through the shaft coupling 42, and the frequency conversion reduction motor with the encoder 36 is mounted on platform 37 .

[0052] Action description:

[0053] 1. The mobile frame 41 is driven by the motor and the trolley moves to the edge of the steel plate.

[0054] 2. When the detection switch 34 detects the edge of the strip, the clamping device presses down to clamp the edge of the strip.

[0055] 3. The control system adjusts the position of the mo...

Embodiment 3

[0059] This embodiment protects a method for controlling a fully automatic strip sewing machine, the method comprising the following steps:

[0060] (1) Determine the parking position of the belt tail: the belt tail of the steel belt runs forward under the drive of the tension roller of the centering platform a1, flicks the tail according to the program setting, and the belt tail automatically stops within 1000mm in front of the alignment switch of the centering platform. After the tail flick is over, the pressure roller of the tension roller of the centering platform a1 is pressed down.

[0061] (2) Belt end centering: the support plates of the centering platform a1 and centering platform b3 move closer to the center of the production line according to the preset width of the strip, and push the center of the strip to the center of the production line to complete the centering of the belt end. The backing plate is connected by a pair of rack and pinion mechanisms, and moves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com