A wall painting machine based on a single-degree-of-freedom seven-bar mechanism

A technology of lever mechanism and degree of freedom, applied in the direction of building structure, construction, etc., can solve the problems of low effect, poor paint adhesion, uneven paint coating, etc., to improve efficiency, save working time, and ensure the quality of painting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

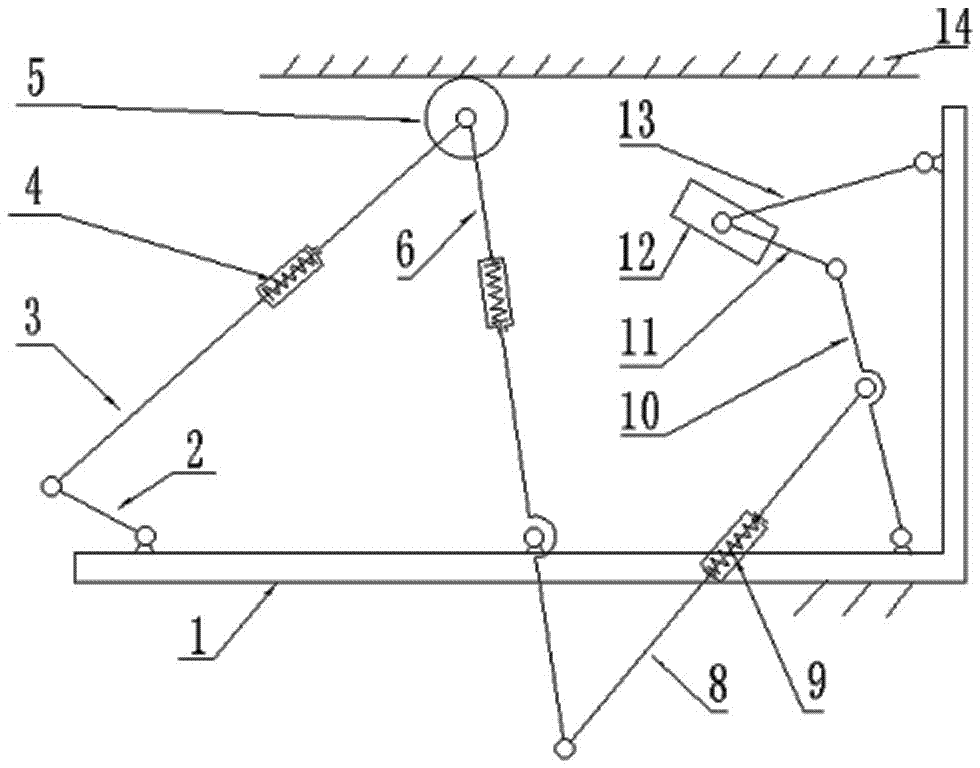

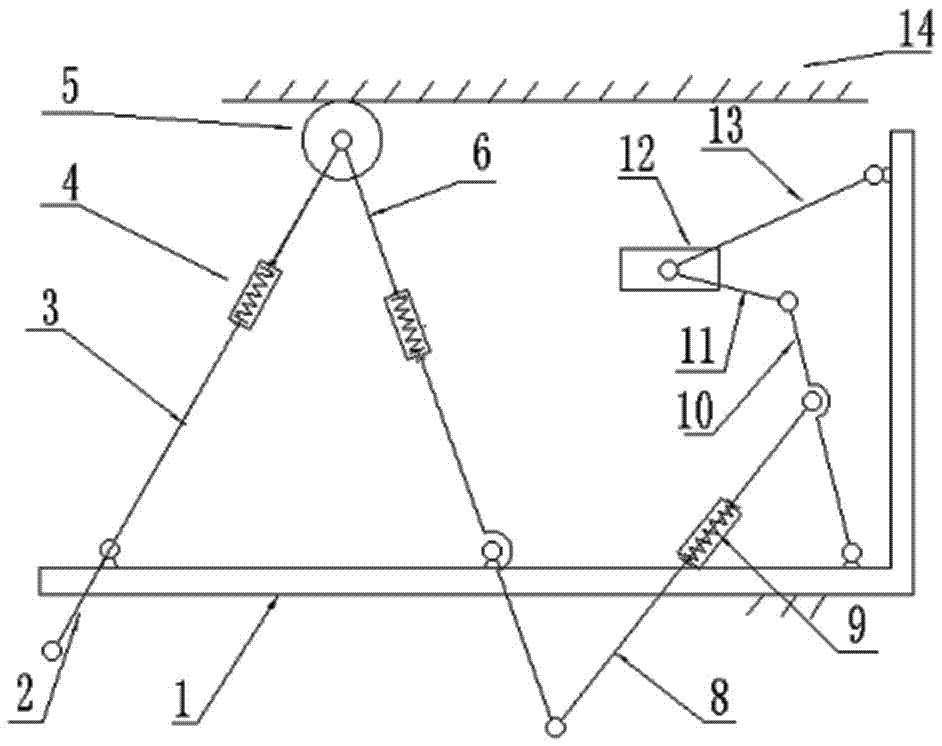

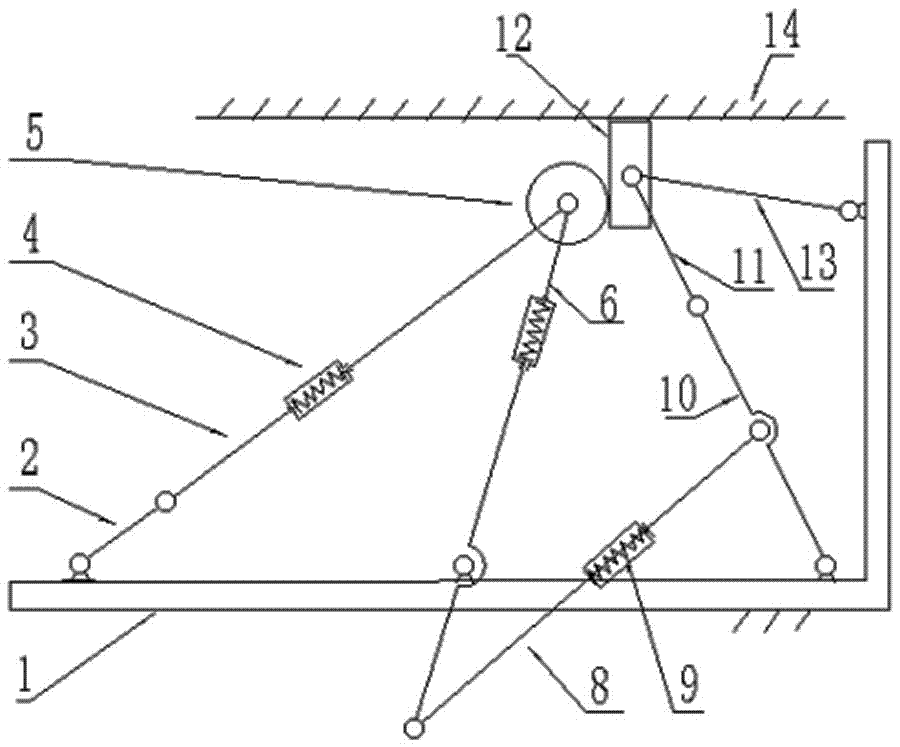

[0037] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0038] see figure 1 , A wall painting machine based on a single-degree-of-freedom seven-bar mechanism includes a motor, a frame 1, a rolling brush 5, a cotton-absorbing pad 12, two elastic compression parts, an elastic extension part 9 and seven rods.

[0039] The frame 1 is a folded plate with an L-shaped cross section, and the motor is fixedly installed at the inner and outer ends of the long side plates of the frame.

[0040] The seven bars are respectively the first bar 2, the fourth bar 8, the fifth bar 10, the sixth bar 11 and the seventh bar 13, wherein the third bar 6 and the fifth bar 10 are levers.

[0041] The first rod 2, the second rod 3, the third rod 6 and the fourth rod 8 are hinged head to tail in turn, the other end of the first rod 2 is connected to the output shaft of the motor, and the lever fulcrum of the third rod 6 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com