Multi-degree-of-freedom switching device for advance drilling machine of shield heading machine

A technology of advanced drilling rigs and transfer devices, which is applied in earthwork drilling, mining equipment, tunnels, etc., and can solve problems such as difficulty in installing advanced drilling rigs, loss, and narrow structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

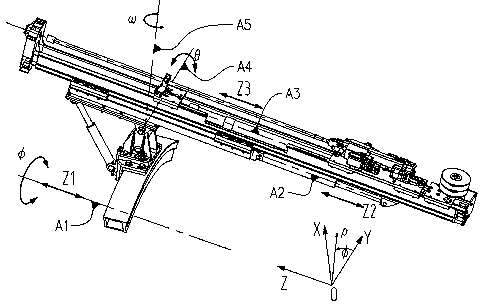

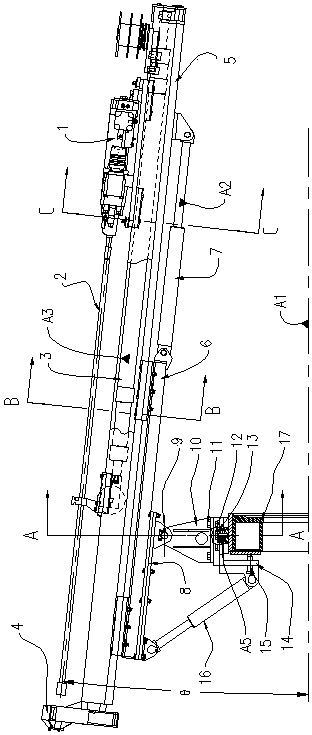

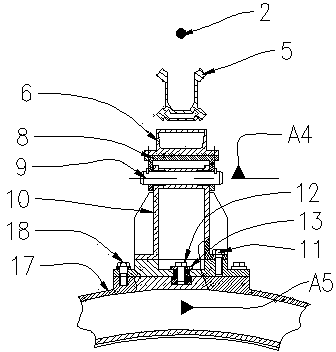

[0021] A multi-degree-of-freedom transfer device for an advanced drilling machine in a shield tunneling machine, such as Figures 1 to 8 As shown, it includes an advance rig mount 1 , a push beam assembly 5 , a joist 6 , a bracket 8 , an adapter frame 10 , a bottom bracket 14 and a rig interface 17 . The advance drilling rig mounting part 1 is positioned above the advancing beam assembly 5 , and the leading drilling rig mounting part 1 is slidingly connected with the advancing beam assembly 5 . The joist 6 is located below the push beam assembly 5 , and the push beam assembly 5 is slidably connected to the joist 6 . The bracket 8 is arranged below the joist 6 , the bracket 8 is located above the adapter frame 10 , and the middle part of the bracket 8 is hingedly connected with the adapter frame 10 . The adapter frame 10 and the bottom bracket 14 are connected toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com