High-magnetism vortex-type ultrafine bubble generation cavity and aerator thereof

A technology of ultra-fine air bubbles and aeration devices, applied in water aeration, sustainable biological treatment, mixers, etc., can solve the problems of high difficulty in system operation and maintenance, high resistance of air-water mixture, and the need for manual operation, etc., to achieve Solve the effect that cannot continue to improve, facilitate flocculation and sedimentation, and realize fully automatic work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

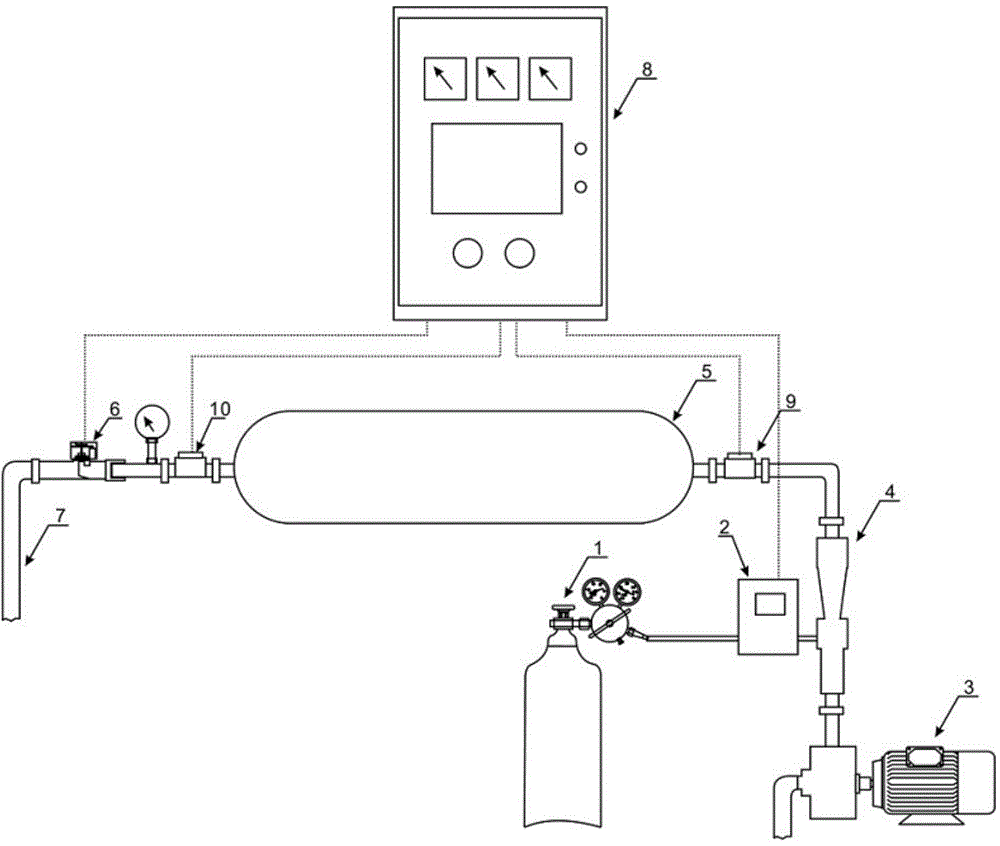

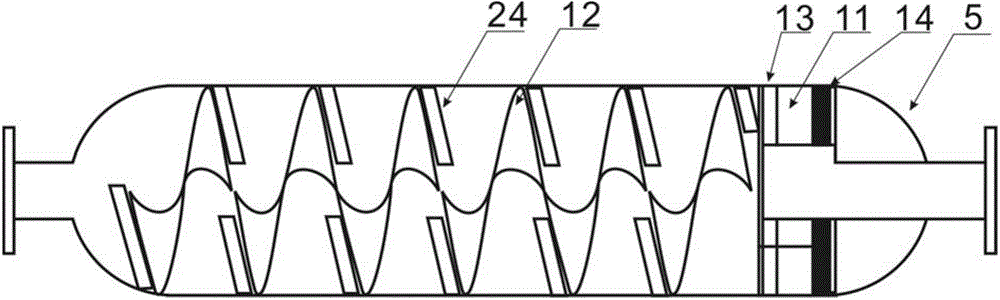

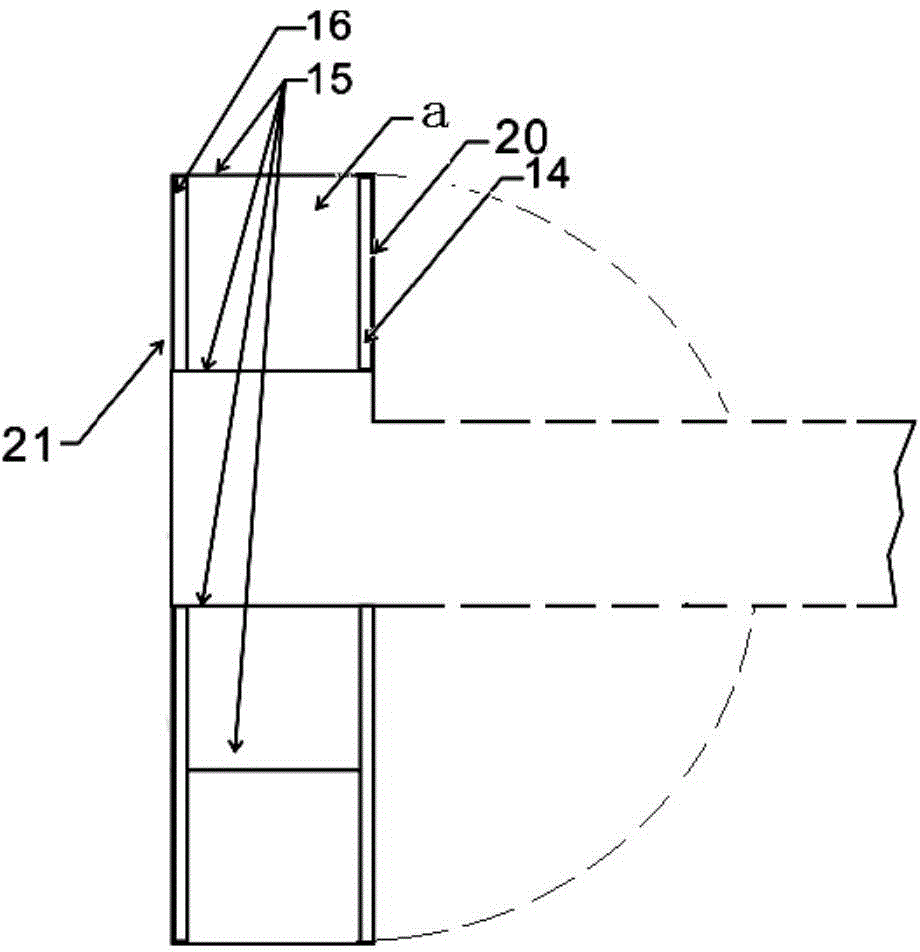

[0030] Such as figure 1 As shown, the device includes: oxygen source 1, oxygen flow regulating valve 2, self-priming water pump 3, Venturi management tube 4, strong magnetic vortex type ultra-fine bubble generation chamber 5, controllable release head 6, water outlet pipe 7 , controller 8, water inlet pressure sensor 9 and water outlet pressure sensor 10, wherein: oxygen source 1 is connected to the negative pressure interface of Venturi management tube 4 through oxygen flow regulating valve 2; the water inlet of Venturi management tube 4 is connected to the self-priming The water outlet of the water pump 3 is connected, and the water outlet of the Venturi management tube 4 is connected with the water inlet of the strong magnetic vortex ultrafine bubble generation chamber 5; the water outlet of the strong magnetic vortex ultrafine bubble generation chamber 5 is released through a controllable The head 6 is connected to the water outlet pipe 7, and the water inlet and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com