Preparation method of high-graphitized nanometer carbon material

A nano-carbon material and graphitization technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high cost, complex shape control method, expensive conductive polymer precursor, etc., and achieve low cost and high raw material Wide range of options, uniform and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

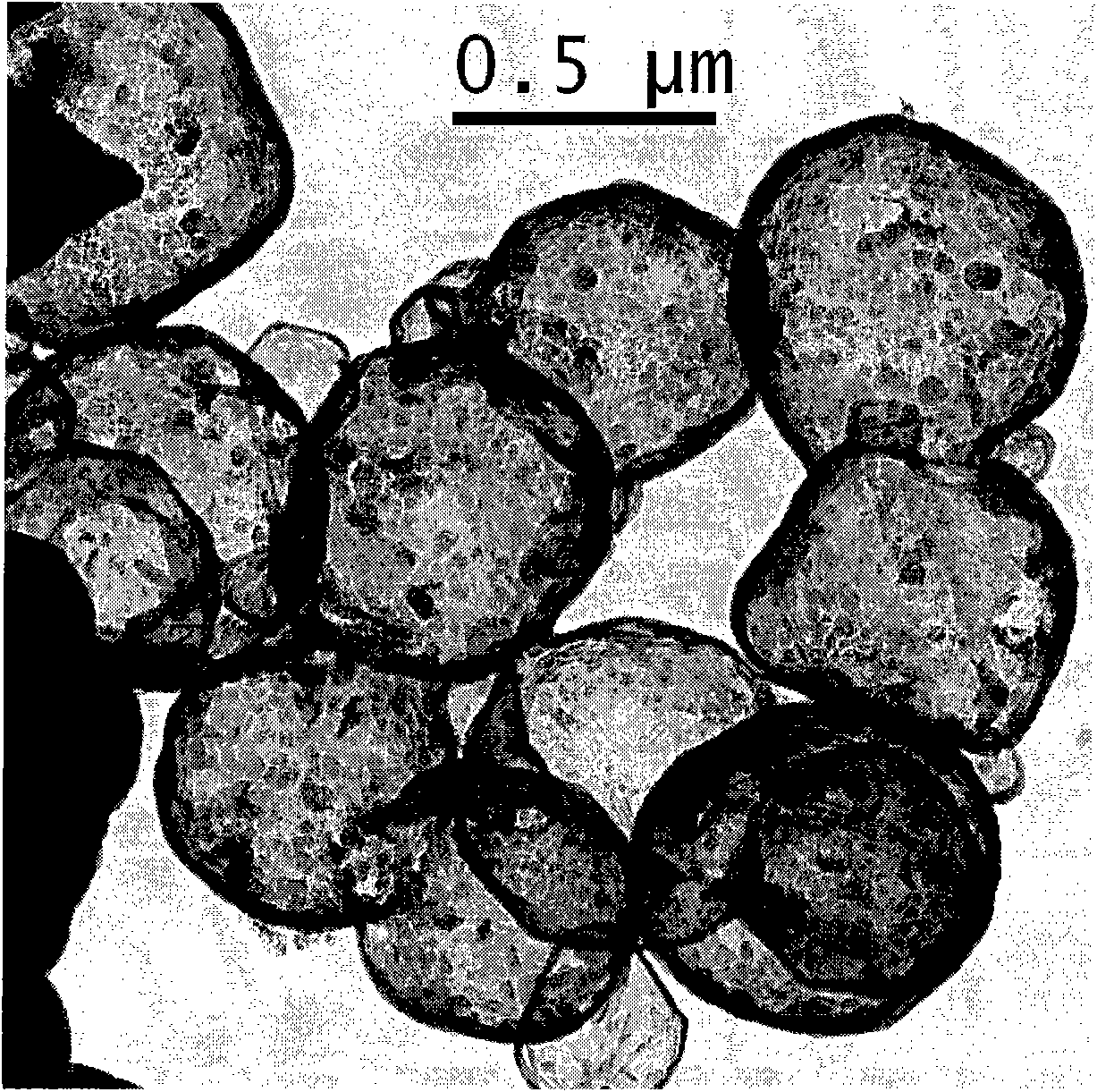

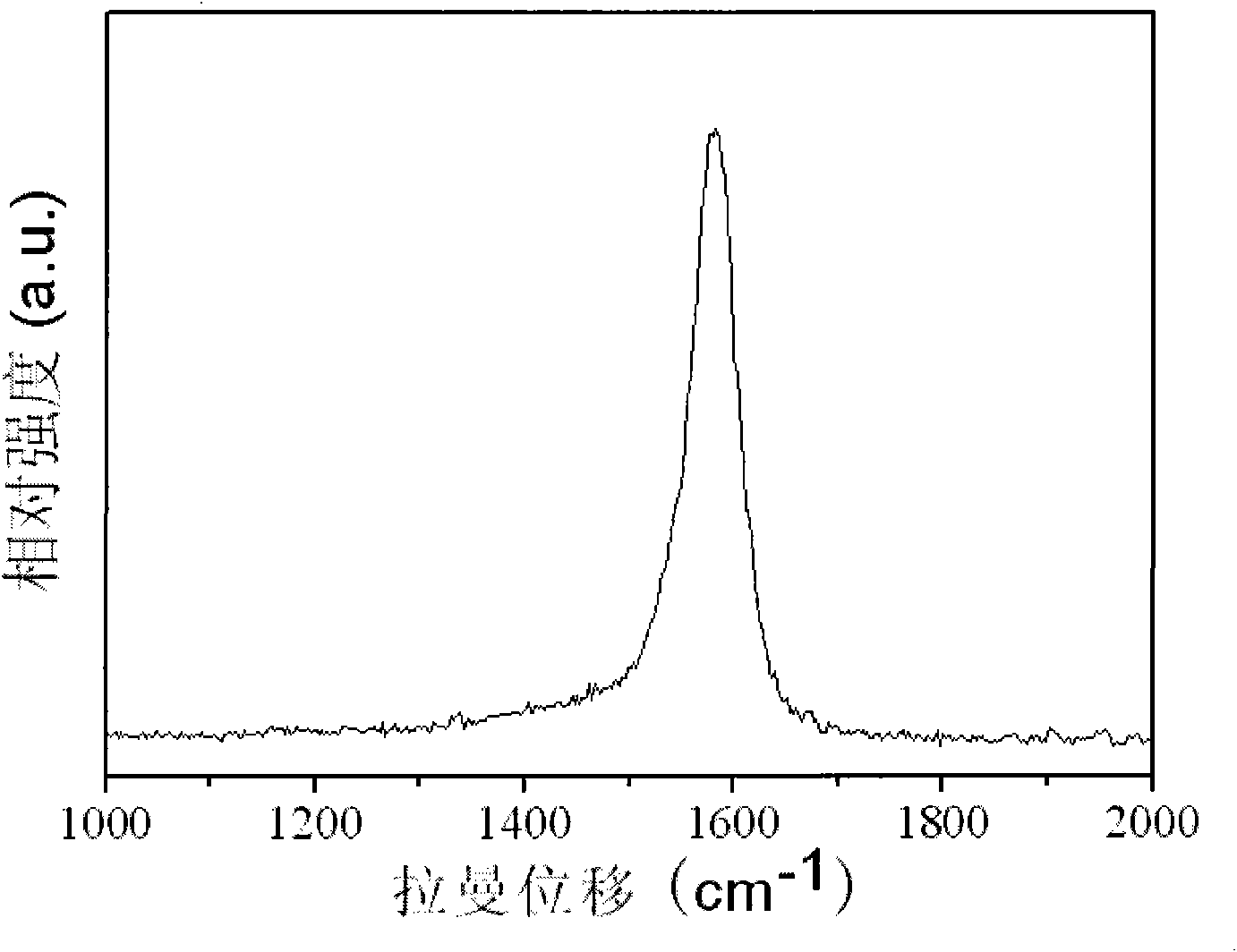

[0033] Weigh 0.5g polystyrene, dissolve it in 20ml ethyl acetate, add 0.5g of 600nm Ni particle powder prepared by polyol method, ultrasonic for 10 minutes, make the Ni particles uniformly dispersed in the solution, use a rotary evaporator to evaporate the solvent , To obtain a uniformly dispersed Ni / PS black mixture. Transfer the mixture to a glass vial, heat it in a microwave oven for 1 minute (Haier Haier MA 2270EGC household microwave oven, microwave frequency 2.45GHz, output power 700W), take it out after cooling, and obtain graphite carbon-coated metal Ni particles. The particles still maintain their original size. The obtained particles were added to 20ml of 1M hydrochloric acid, sonicated for 2 hours to dissolve most of Ni, centrifuged, washed, and dried to obtain hollow carbon balls ( figure 1 ), the thickness of the spherical shell is about 15-50nm. Raman scattering spectrum of the product ( figure 2 ) There is only G-band related to graphitic carbon and no D-band repr...

Embodiment 2

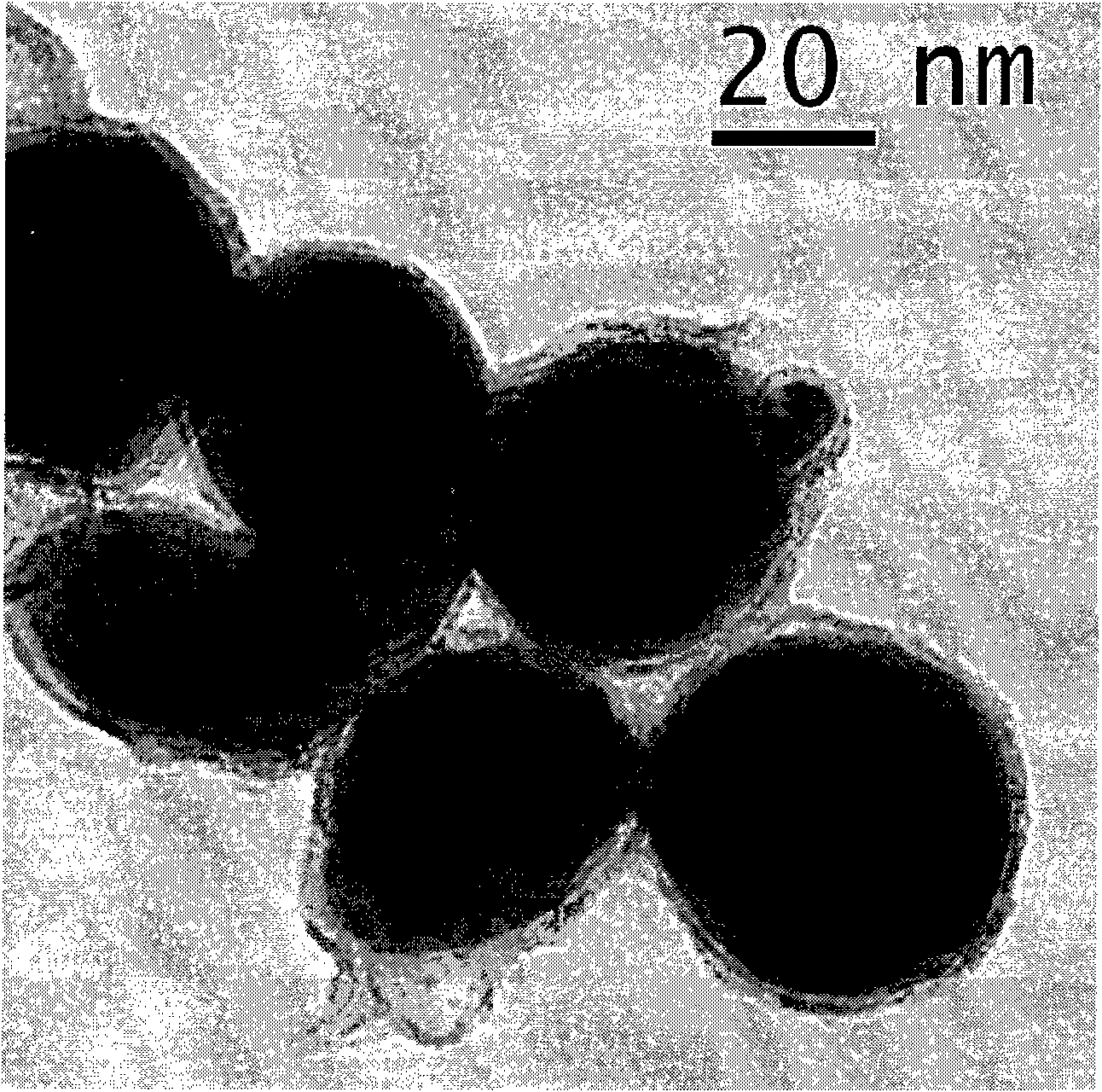

[0035] Weigh 0.5g polystyrene, dissolve it in 20ml ethyl acetate, add 0.5g 40nm Ni particle powder prepared by polyol method, ultrasonic for 10 minutes, make the Ni particles uniformly dispersed in the solution, use a rotary evaporator to evaporate the solvent , To obtain a uniformly dispersed Ni / PS black mixture. This mixture was transferred to a glass vial, placed in a microwave oven and heated for 1 minute (the microwave conditions were the same as in Example 1), and then taken out after cooling to obtain graphite carbon coated metal Ni particles ( image 3 ), Ni particles still maintain the original size. Add the obtained particles to 20ml of 1M hydrochloric acid, sonicate for 0.5 hours, centrifuge, wash, and dry to obtain the remaining metal carbon balls ( Figure 4 ), the thickness of the spherical shell is about 2-5nm. Ultrasonic treatment for more than 2 hours can obtain hollow carbon balls.

Embodiment 3

[0037] Weigh 0.4g polystyrene and dissolve it in 20ml ethyl acetate, then add 0.2g of 8nm Ni particle powder prepared by microemulsion method, ultrasonic for 10 minutes, make the Ni particles uniformly dispersed in the solution, and use a rotary evaporator to evaporate the solvent , To obtain a uniformly dispersed Ni / PS black mixture. Transfer the mixture to a glass vial, heat it in a microwave oven for 1 minute (Panasonic NN-GD586A household microwave oven, microwave frequency 2.45GHz, output power 1000W), take it out after cooling, and treat with 1M hydrochloric acid for 2 hours to obtain hollow graphite carbon Ball and multi-walled carbon nanotube mixture ( Figure 5 and Figure 6 ), the carbon tube content is about half, the tube diameter is 8-13nm, and the carbon tube length is 200-600nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com