All-biomass composite modified foamed material and preparation method thereof

A technology of composite modified and foamed materials, which is applied in the field of ecological environment materials and new materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of above-mentioned a kind of whole biomass composite modified foam material, it comprises the steps:

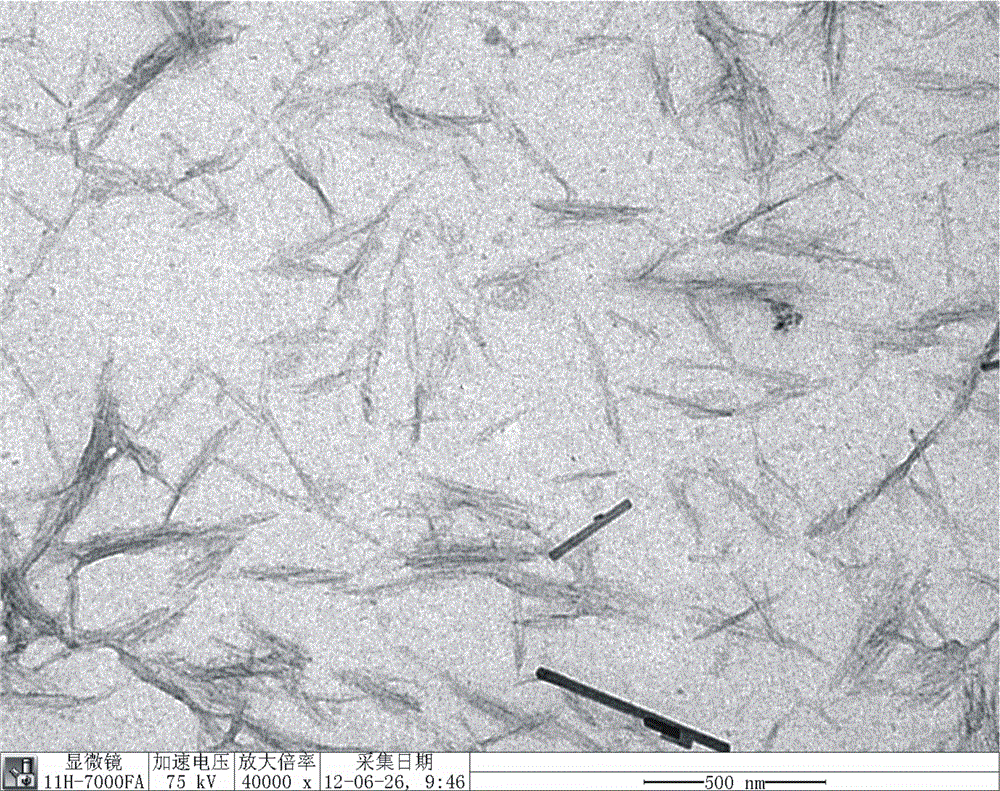

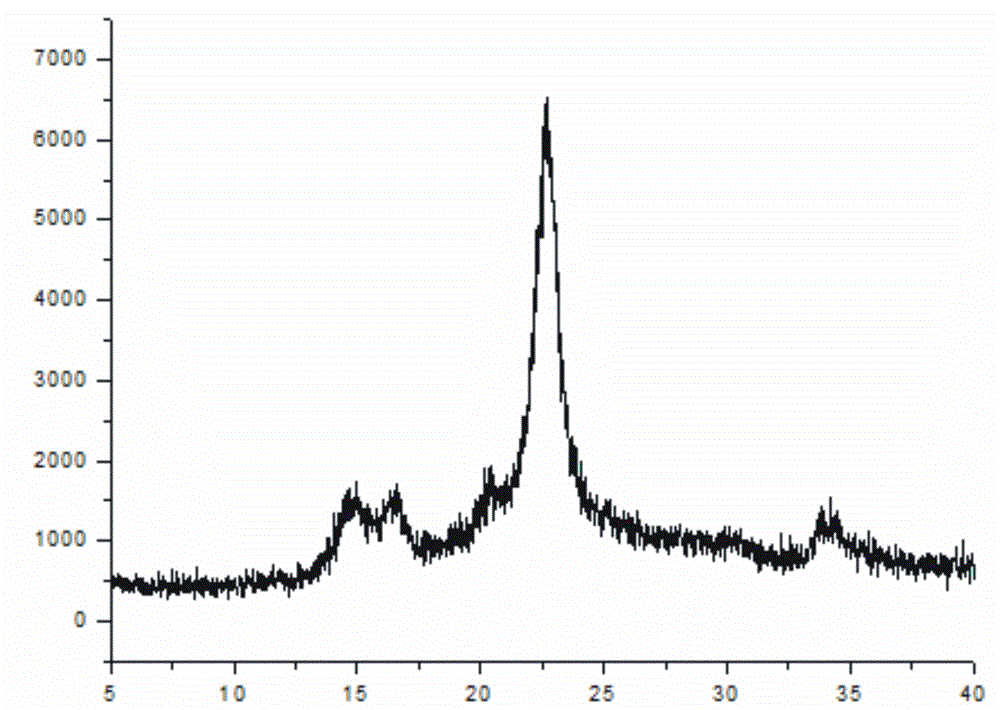

[0034] ①According to mass percentage, 3% of cellulose nanocrystals, 92% of polybutylene succinate, 3% of foaming agent AC (ie, azodicarbonamide) and 2% of zinc oxide were selected and mixed to obtain blends.

[0035] ② Banbury the blend in an internal mixer (China Changzhou Suyan Technology Co., Ltd., the following examples are the same). The technical conditions for banburying are: temperature 130°C, rotation speed 72rpm (rev / min), and time of 15min, to obtain a solid mixture;

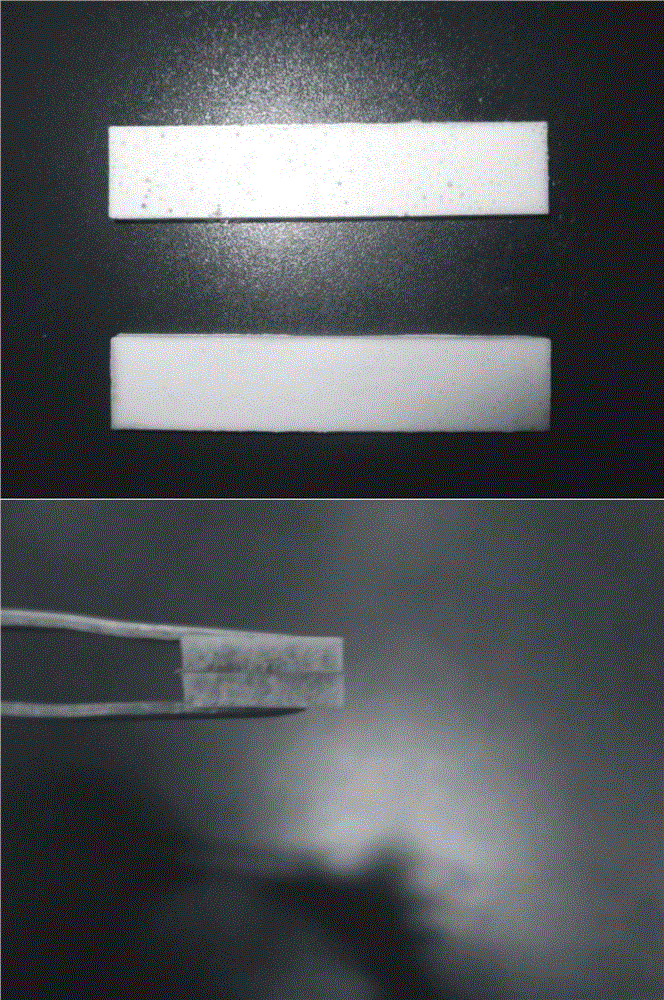

[0036]③The solid mixture is hot-compressed and composite-molded in a hot-press machine (Tianjin Keqi High-tech Co., Ltd., the following examples are the same), the temperature is 170°C, the pressure is 10MPa, and the time is 10min. After cooling and forming, vacuum at 40°C Dry for 12 hours to remove moisture, and obtain the cellulose nanocrystal modified polyester foam...

Embodiment 2

[0041] The preparation method of above-mentioned a kind of whole biomass composite modified foam material, it comprises the steps:

[0042] ①Based on mass percentage, 5% of cellulose nanocrystals, 90% of polybutylene succinate, 3% of foaming agent AC, and 2% of zinc oxide were selected and mixed to obtain a blend.

[0043] ② Banbury the blend in a banbury mixer. The technical conditions of banbury mixing are: temperature 120°C, rotation speed 48rpm, time 30min, to obtain a solid mixture;

[0044] ③Put the solid mixture in a hot press for hot-compression composite molding at a temperature of 160°C, a pressure of 20MPa, and a time of 3 minutes. After cooling and molding, it is vacuum-dried at 40°C for 12 hours to remove moisture, and the modified cellulose nanocrystals are obtained. Polyester foam material, that is, all biomass composite modified foam material.

[0045] The obtained all-biomass composite modified foam material, according to GB / T 9431-2000, when the maximum bend...

Embodiment 3

[0048] The preparation method of above-mentioned a kind of whole biomass composite modified foam material, it comprises the steps:

[0049] ①Based on mass percentage, 7% of cellulose nanocrystals, 88% of polybutylene succinate, 3% of foaming agent AC, and 2% of zinc oxide were selected and mixed to obtain a blend.

[0050] ② Banbury the blend in a banbury mixer. The technical conditions for banbury mixing are: temperature 130°C, rotation speed 96rpm, time 10min, to obtain a solid mixture;

[0051] ③Put the solid mixture in a hot press for hot-compression composite molding at a temperature of 180°C, a pressure of 5MPa, and a time of 20 minutes. After cooling and molding, it is vacuum-dried at 40°C for 12 hours to remove moisture, and the modified cellulose nanocrystals are obtained. Polyester foam material, that is, all biomass composite modified foam material.

[0052] The obtained all-biomass composite modified foam material, according to GB / T 9431-2000, when the maximum ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com