Sodium-ion battery negative electrode material and preparation method thereof

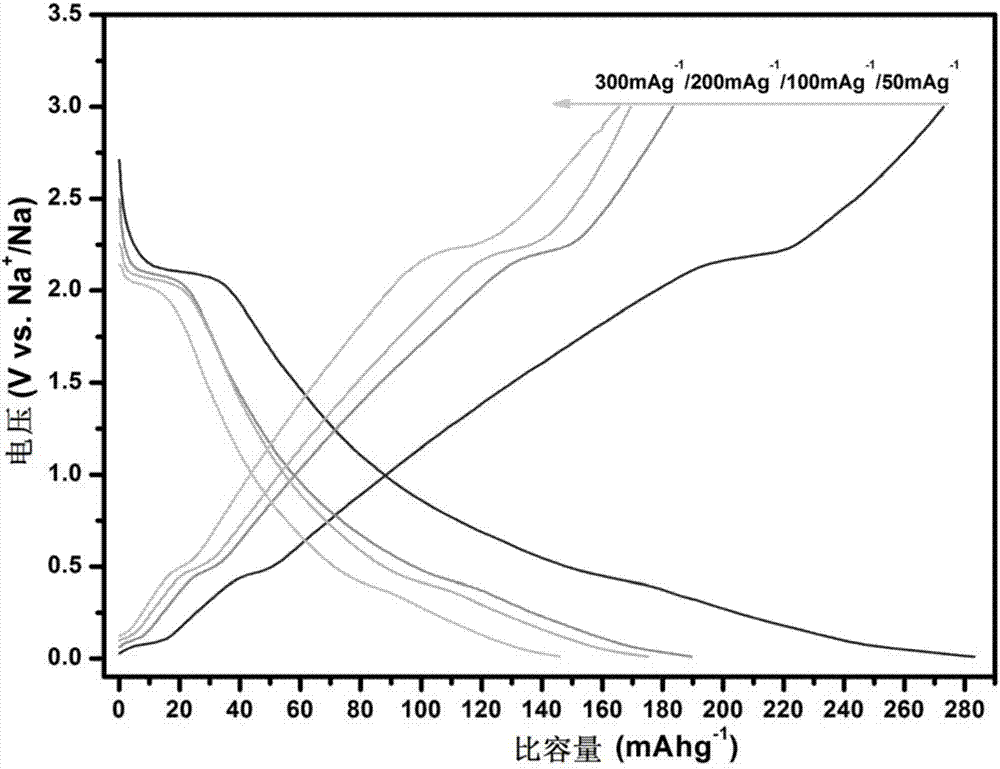

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high voltage platform, low energy density, poor cycle performance and rate performance, and achieve low working voltage and high energy density , The effect of good magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] On the other hand, the embodiment of the present invention also provides a preparation method of the above-mentioned negative electrode material for a sodium ion battery, the preparation method comprising the following steps:

[0024] S01: Obtain manganese source, titanium source, phosphorus source and chelating agent;

[0025] S02: Dissolve the above manganese source, titanium source, phosphorus source and chelating agent in water, and dry in a water bath to obtain Mn 0.5 Ti 2 (PO 4 ) 3 Sol;

[0026] S03: Vacuum-dry or freeze-dry the above mixed sol to obtain Mn 0.5 Ti 2 (PO 4 ) 3 Precursor;

[0027] S04: The above Mn 0.5 Ti 2 (PO 4 ) 3 The precursor is calcined under an inert atmosphere to obtain a negative electrode material for a sodium ion battery.

[0028] The preparation method of the anode material of the above-mentioned sodium ion battery is mainly formed by sintering the manganese source, the titanium source, the phosphorus source and the chelatin...

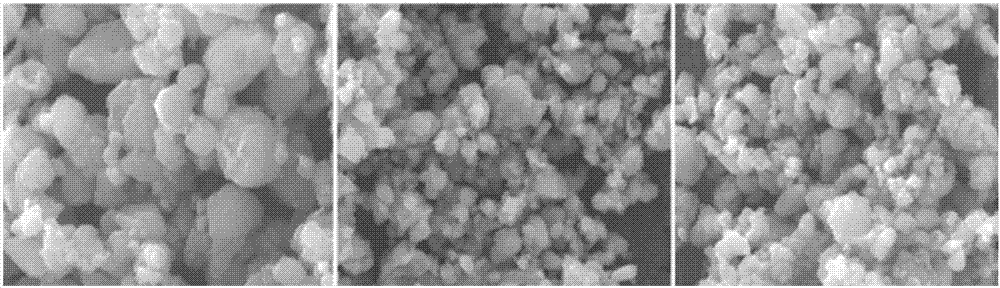

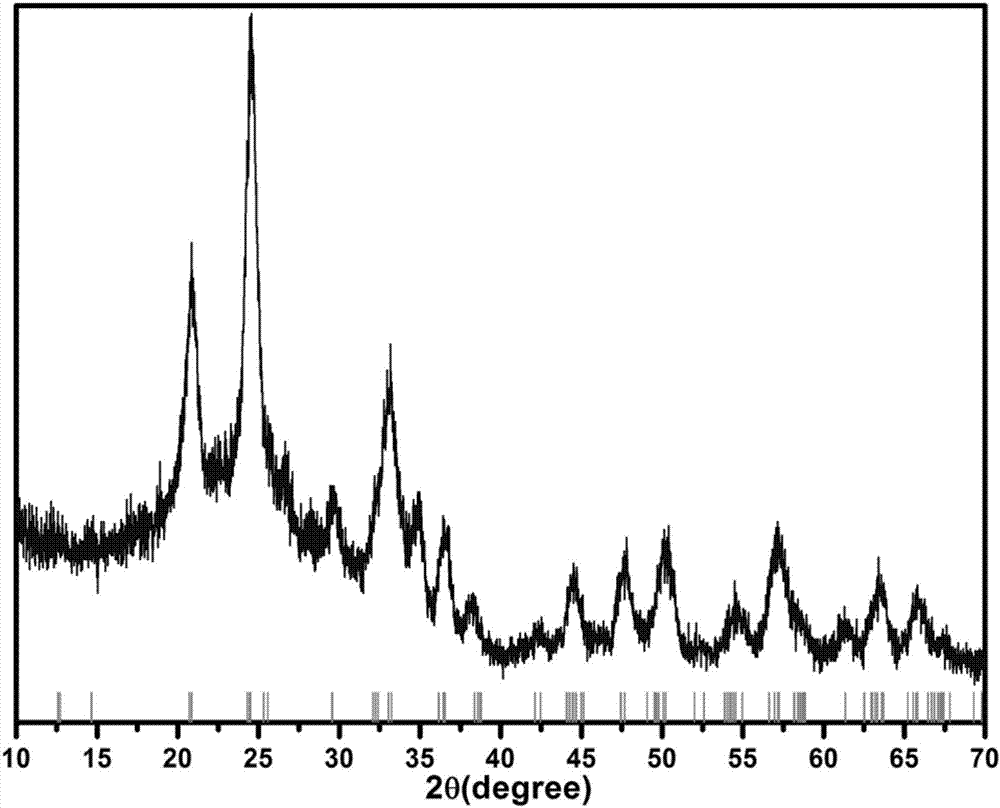

Embodiment 1

[0036] A negative electrode material for a sodium ion battery, comprising a manganese-titanium-phosphorus ternary material and a carbon coating layer coated on the particle surface of the manganese-titanium-phosphorus ternary material, and the general formula of the manganese-titanium-phosphorus ternary material is Mn 0.5 Ti 2 (PO 4 ) 3 . The steps of the preparation method of the sodium ion battery negative electrode material are as follows:

[0037] S11: Obtain 1 mmol of manganese acetate, 4 mmol of tetrabutyl titanate, 6 mmol of phosphoric acid and 2 mmol of citric acid.

[0038] S12: Dissolve the above-mentioned manganese acetate, citric acid, tetrabutyl titanate and phosphoric acid in water, and dry in a water bath to obtain Mn 0.5 Ti 2 (PO 4 ) 3 Sol; the specific process is: first dissolve manganese acetate in 50ml deionized water, then dissolve citric acid in it, and finally dissolve tetrabutyl titanate and phosphoric acid in it, and keep stirring until the solut...

Embodiment 2

[0042] A negative electrode material for a sodium ion battery, comprising a manganese-titanium-phosphorus ternary material and a carbon coating layer coated on the particle surface of the manganese-titanium-phosphorus ternary material, and the general formula of the manganese-titanium-phosphorus ternary material is Mn 0.5 Ti 2 (PO 4 ) 3 . The steps of the preparation method of the sodium ion battery negative electrode material are as follows:

[0043] S21: 3 mmol of manganese oxalate, 12 mmol of tetrabutyl titanate, 18 mmol of ammonium dihydrogen phosphate and 1 mmol of citric acid were obtained.

[0044] S22: Dissolve the above-mentioned manganese oxalate, citric acid, tetrabutyl titanate and ammonium dihydrogen phosphate in water, and dry in a water bath to obtain Mn 0.5 Ti 2 (PO 4 ) 3 Sol; the specific process is: first dissolve manganese oxalate in 150ml deionized water, then dissolve citric acid in it, and finally dissolve tetrabutyl titanate and ammonium dihydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com