Method for producing carbon composite amorphous vanadium oxide powder

An amorphous, vanadium oxide technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of limited application, high resistance, poor conductivity, etc., to achieve high capacity, low energy consumption, and prevent agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

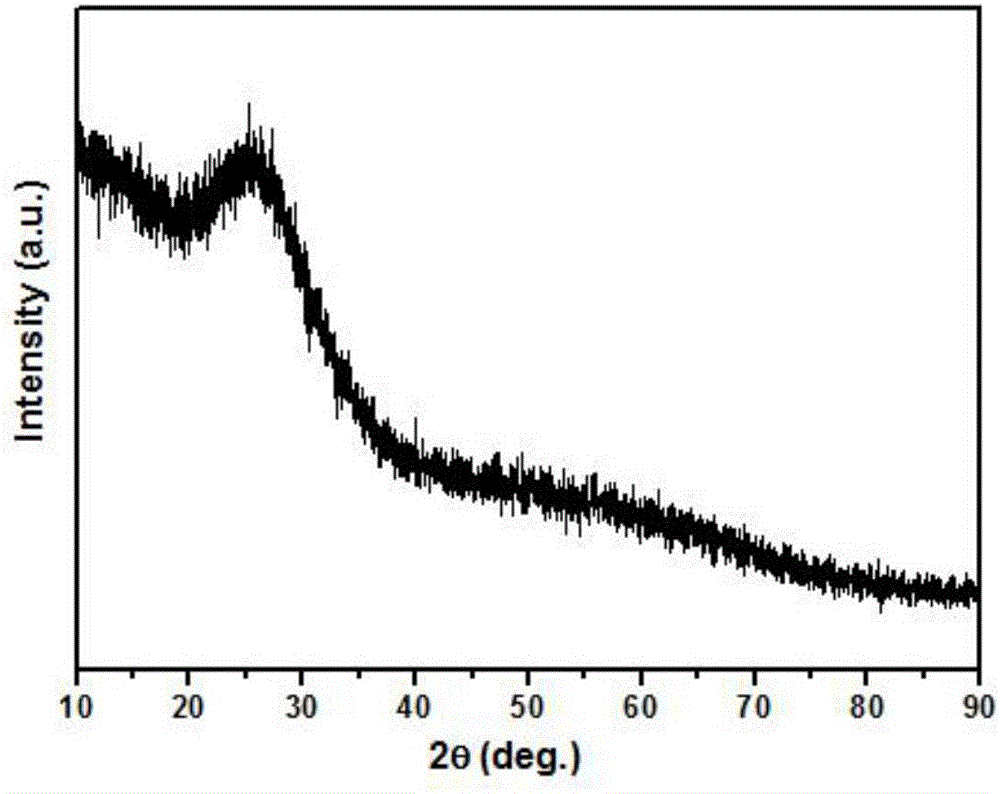

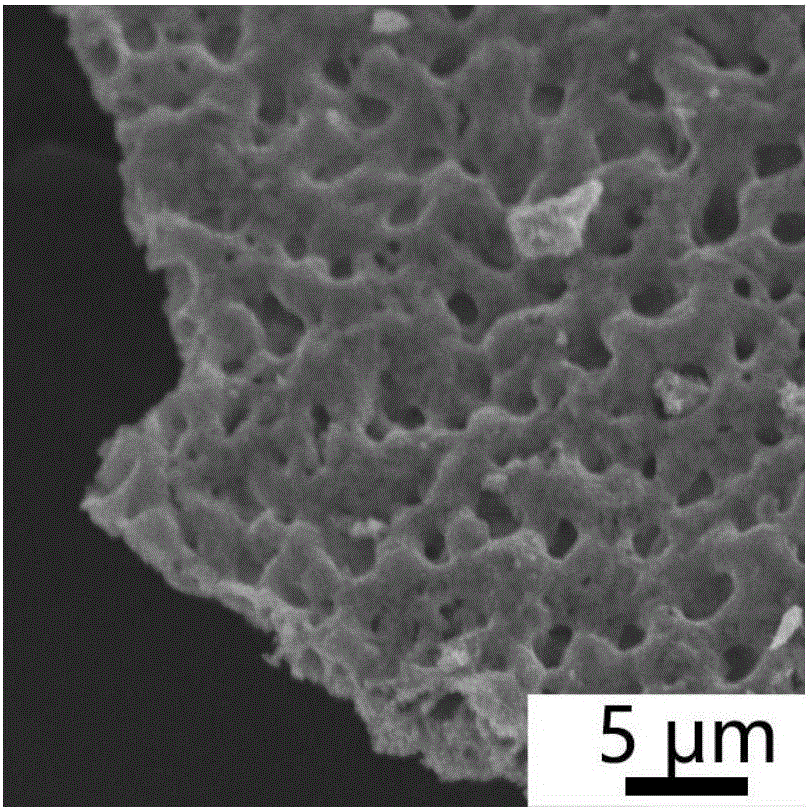

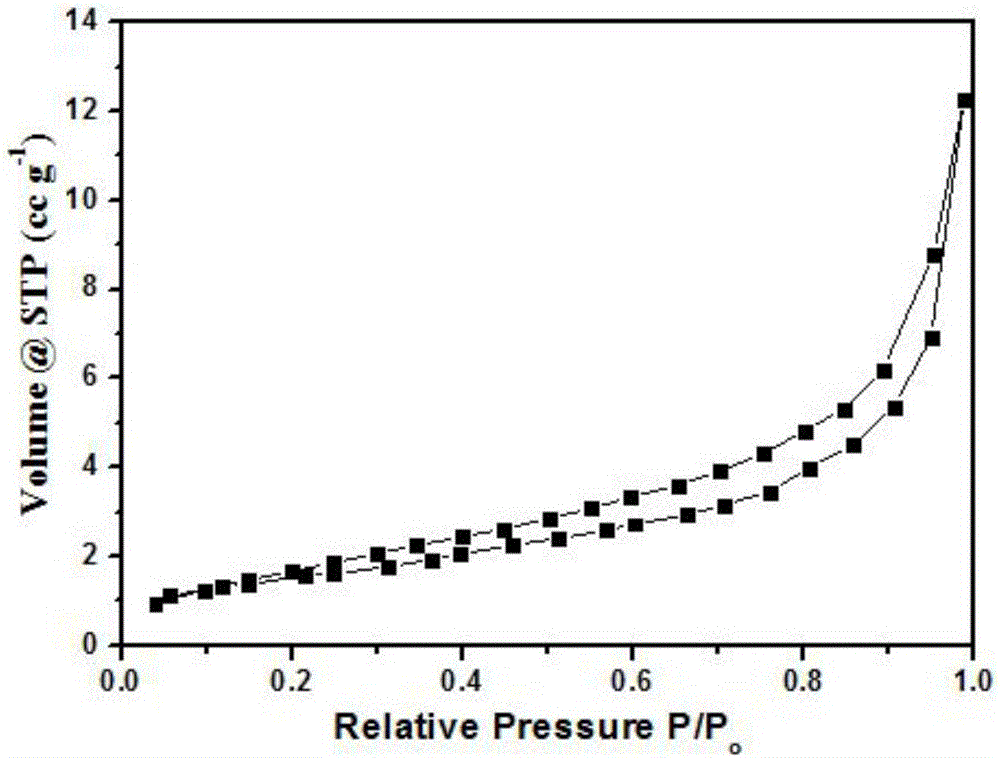

[0023] Weigh 0.1 mol of ammonium metavanadate, 0.8 mol of ammonium nitrate, 0.3 mol of citric acid, 0.08 mol of glycine, and 0.02 mol of glucose to prepare a solution, and uniformly mix vanadate ions and carbon source molecules in the solution. The solution was placed on a furnace and heated under air. After the solution is boiled and evaporated to form a gel, a combustion synthesis reaction occurs, and finally carbon-composite amorphous vanadium oxide powder is obtained.

Embodiment 2

[0025] Weigh 0.1 mol of ammonium metavanadate, 0.8 mol of ammonium nitrate, 0.3 mol of citric acid, 0.08 mol of glycine, and 0.03 mol of glucose to prepare a solution, place the solution on a heating furnace, and heat it under air. After the solution is boiled and evaporated to form a gel, a combustion synthesis reaction occurs to obtain carbon-composite amorphous vanadium oxide powder.

Embodiment 3

[0027] Weigh 0.06 moles of ammonium metavanadate, 0.8 moles of ammonium nitrate, 0.3 moles of citric acid, 0.08 moles of glycine, and 0.01 moles of glucose to prepare a solution, place the solution on a heating furnace, and heat it under air. After the solution is boiled and evaporated to form a gel, a combustion synthesis reaction occurs to obtain carbon-composite amorphous vanadium oxide powder.

[0028] test results

[0029] The carbon-composite amorphous vanadium oxide material obtained in the above three examples is used as the active material, and conductive carbon black (Super P) and polyvinylidene fluoride (PVDF) are used to make the negative electrode of the lithium battery according to the mass ratio of 60:30:10 Material. Disperse the mixture into NMP solution to make a slurry, then apply the slurry evenly on the copper foil with a blade, dry it in a vacuum oven at 120°C for 12 hours, and then dry it at 200kg m -2 pressed into discs under high pressure. The electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com