Preparation method of WC-Co nano powder added with grain growth inhibitor

A technology of grain growth and nano-powder, which is applied in the field of powder metallurgy, can solve the problems of unsuitability for large-scale production, cumbersome preparation methods, and long time consumption, and achieve the effects of fine particles, short diffusion process, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

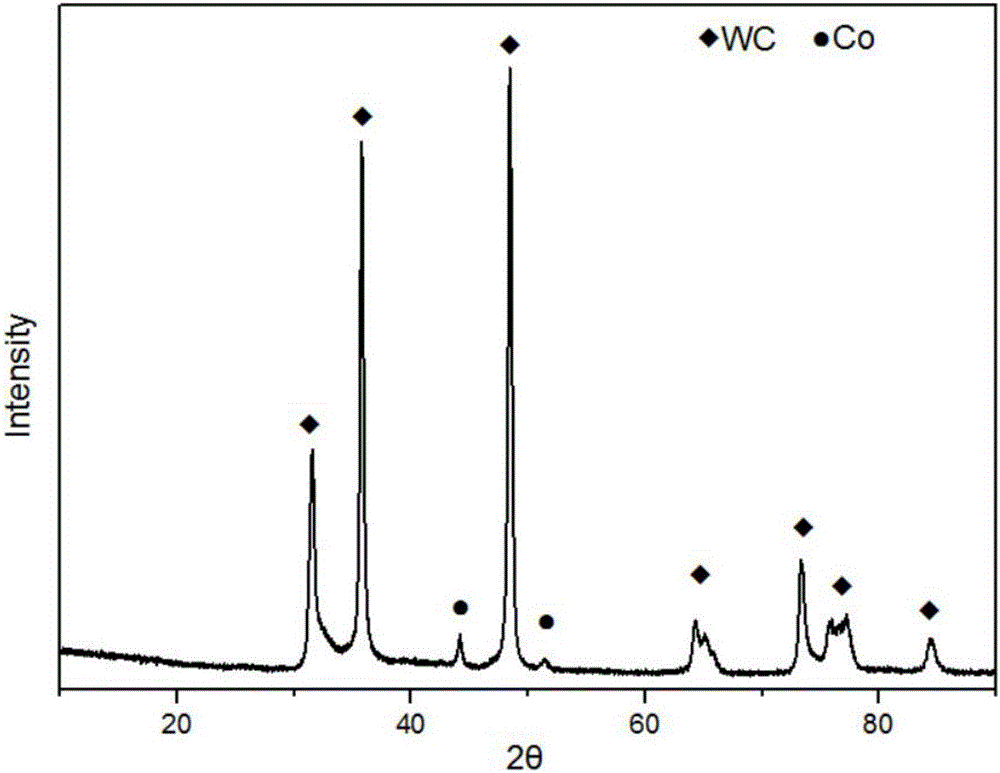

Image

Examples

Embodiment 1

[0022] Put 9.44g of ammonium metatungstate, 5g of cobalt nitrate hexahydrate, 4.3g of urea, 10g of ammonium nitrate, 6.5g of glucose and 0.14g of ammonium vanadate into a beaker and add an appropriate amount of water to dissolve to obtain a clear solution. Heating on an electric furnace until the reaction occurs, and fluffy precursor powder is obtained. Put the precursor powder into a tube furnace for carbonization. The carbonization temperature is 950°C, the holding time is 2.5h, the heating rate is 8°C / min, and the protective atmosphere is argon. WC-Co nano powder.

Embodiment 2

[0024] Put 9.44g ammonium metatungstate, 3.8g cobalt nitrate hexahydrate, 4.3g urea, 10g ammonium nitrate, 6.5g glucose and 0.14g ammonium vanadate into a beaker, add an appropriate amount of water to dissolve to obtain a clear solution, and place the solution in Pre-heated to 260 ° C muffle furnace, after the reaction took out to obtain the precursor powder. Place the body powder in a vacuum furnace for carbonization, the reaction temperature is 900°C, the holding time is 1.5h, the heating rate is 5°C / min, the vacuum degree is 100MPa, and naturally cooled to room temperature to obtain VC-doped WC-Co nanopowder .

Embodiment 3

[0026] Put 18.7g of ammonium metatungstate, 7.57g of cobalt nitrate hexahydrate, 8.5g of urea, 20g of ammonium nitrate, 13g of glucose and 0.5g of chromium nitrate into a beaker, add an appropriate amount of water to dissolve to obtain a clear solution, and place the solution in a preheated Heat it in a muffle furnace at 245°C until the combustion reaction is complete, and take out the precursor powder. Grind the precursor powder, then place it into a tube furnace for carbonization, the carbonization temperature is 1000°C, the holding time is 3h, the heating rate is 10°C / min, and naturally cooled to room temperature to obtain Cr 3 C 2 Doped WC-Co nanopowders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com