Method for synthesizing and preparing module of panda polarization maintaining optical fiber preformed rod

A polarization-maintaining optical fiber, panda-type technology, applied in polarized optical fiber, cladding optical fiber, glass manufacturing equipment, etc., can solve the problems of low production efficiency, poor process repeatability, large positioning deviation, etc., and achieve high processing accuracy, mature technology, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

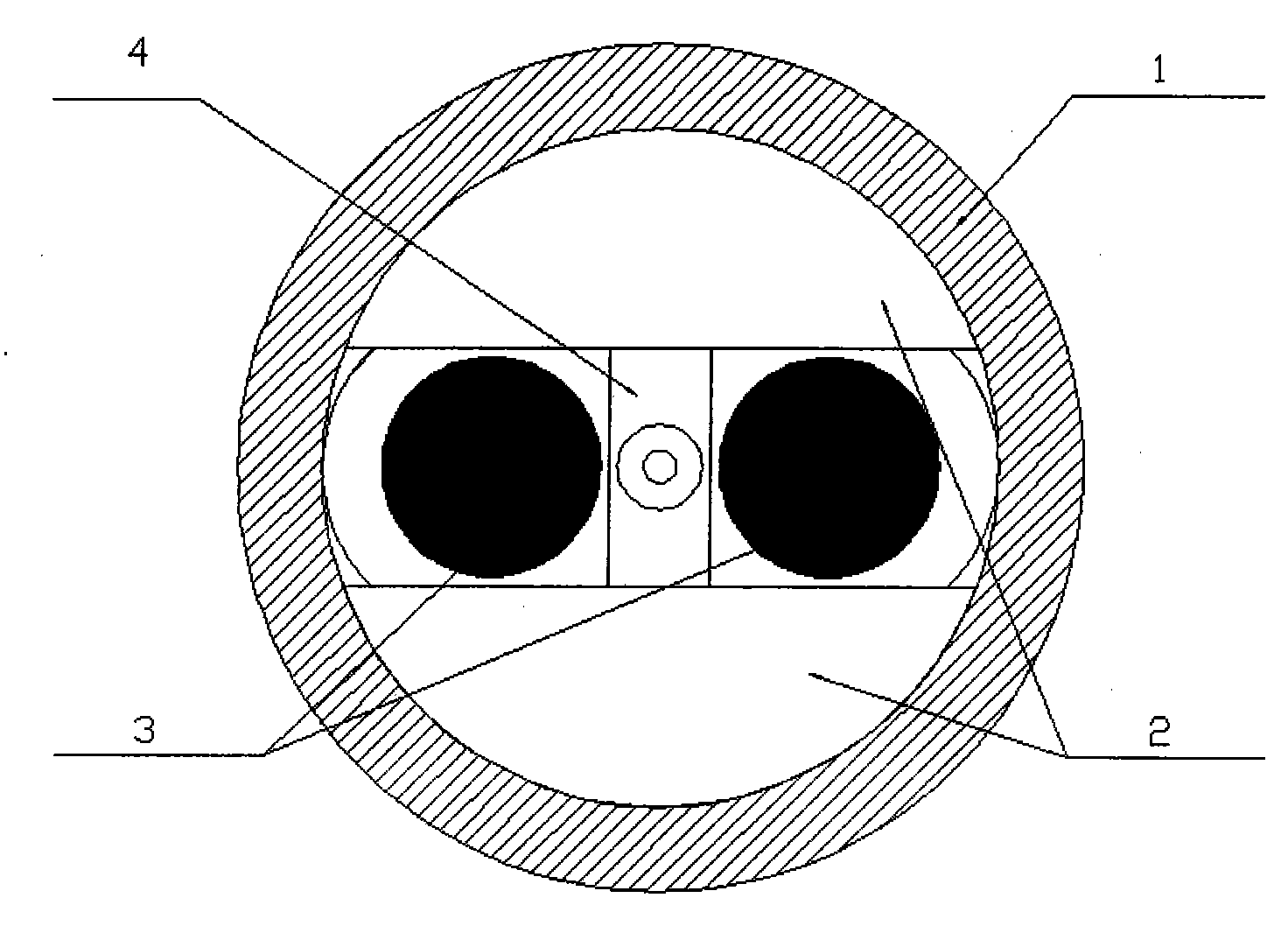

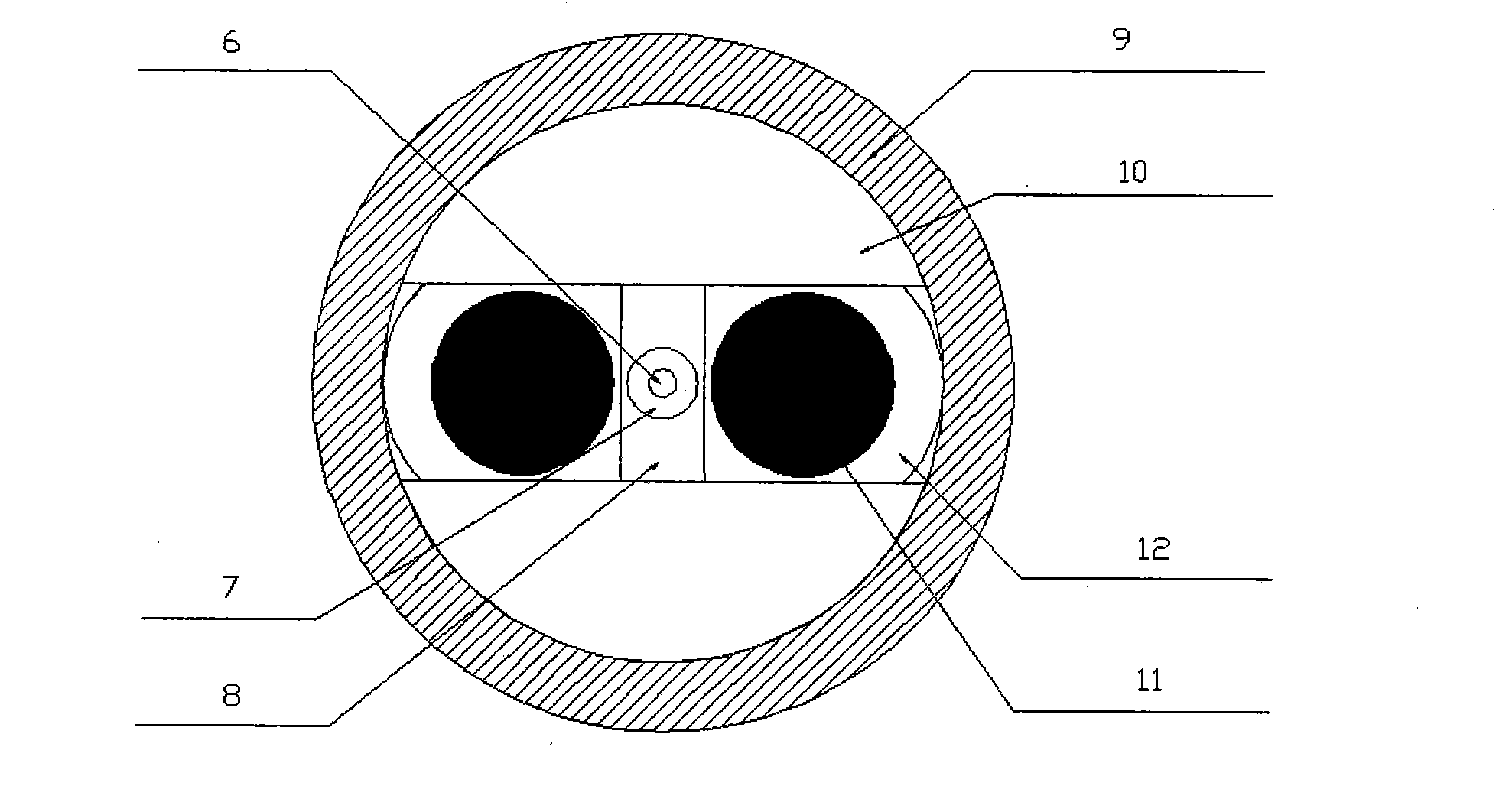

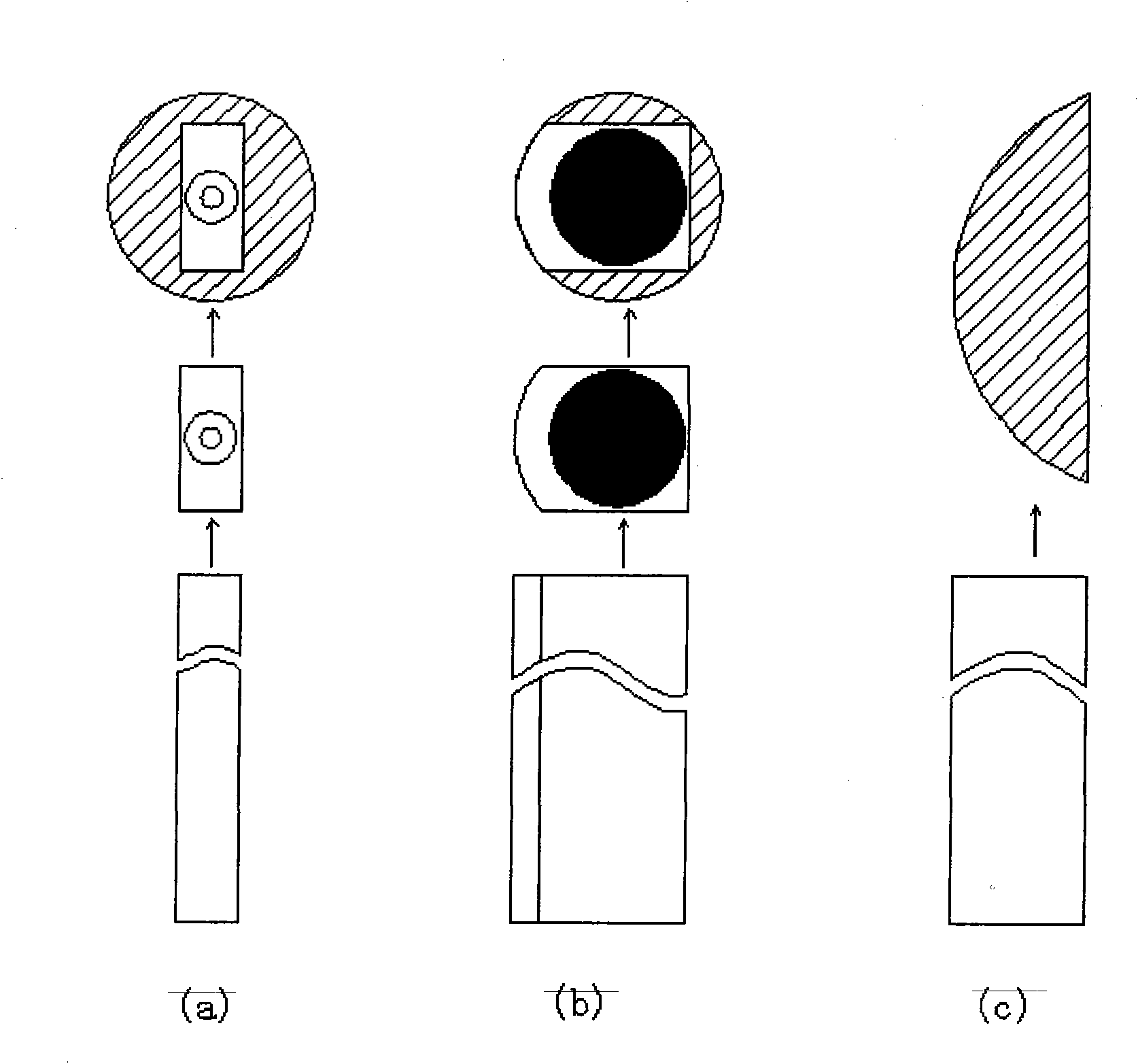

[0021] Figure 1-5 The marks 1-12 indicate circular casing module 1, arc-shaped quartz filling module 2, stress module 3, single-mode module 4, mandrel 5, rod core layer 6, mandrel inner cladding 7, mandrel outsourcing Layer 8, circular casing 9, filling rod 10, stress rod 11, stress rod outer cladding 12.

[0022] This embodiment is based on today's mature high-precision cutting, grinding, polishing technology and equipment, with high-grade quartz pipes and rods selected according to design as auxiliary parts, and core rods and stress rods prepared by MCVD technology. The main part is designed, processed and combined to make a Panda polarization maintaining optical fiber preform.

[0023] In this embodiment, the outer diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com