Rapid preparation method of manganese oxide/carbon sphere composite material for three-dimensional (3D) printing

A composite material, 3D printing technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of low capacitor electrodes, and achieve the effect of advanced technology and accurate and detailed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

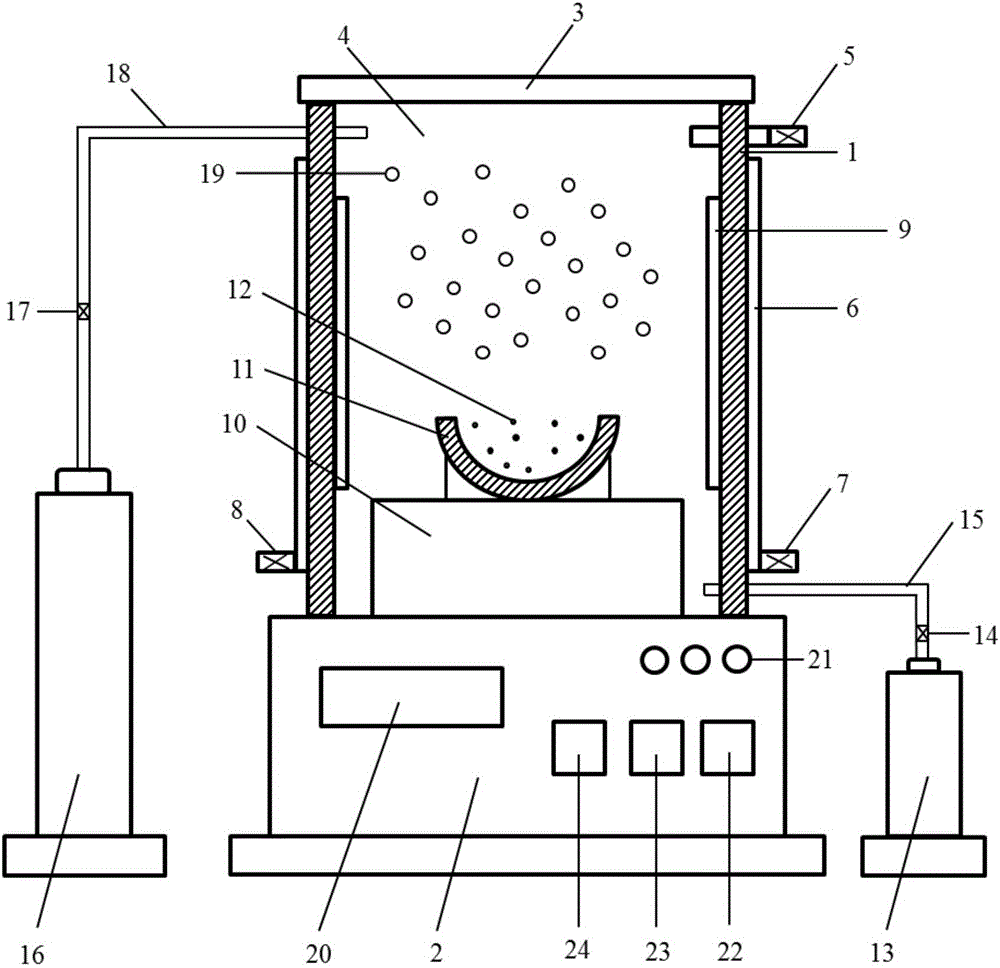

Method used

Image

Examples

Embodiment 1

[0077] 3D printing manganese oxide / carbon sphere composite electrode:

[0078] ①The 3D printer is in the ready-to-work state;

[0079] ② Design the electrode size through computer graphics software and import it into the 3D printer;

[0080] ③ Place the manganese oxide / carbon sphere composite material in the storage box of the 3D printer;

[0081] ④ Turn on the 3D printer, and print the manganese oxide / carbon sphere composite material into electrodes according to the computer program; that is, the whole process of 3D printing is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com