Preparation method of nano aluminium nitride powder

A nano-aluminum nitride and aluminum nitride technology, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of difficult control of combustion temperature, long preparation time of precursors, and difficulty in mass production, etc. The effect of carbothermal reduction reaction temperature, fine aluminum source particles, and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

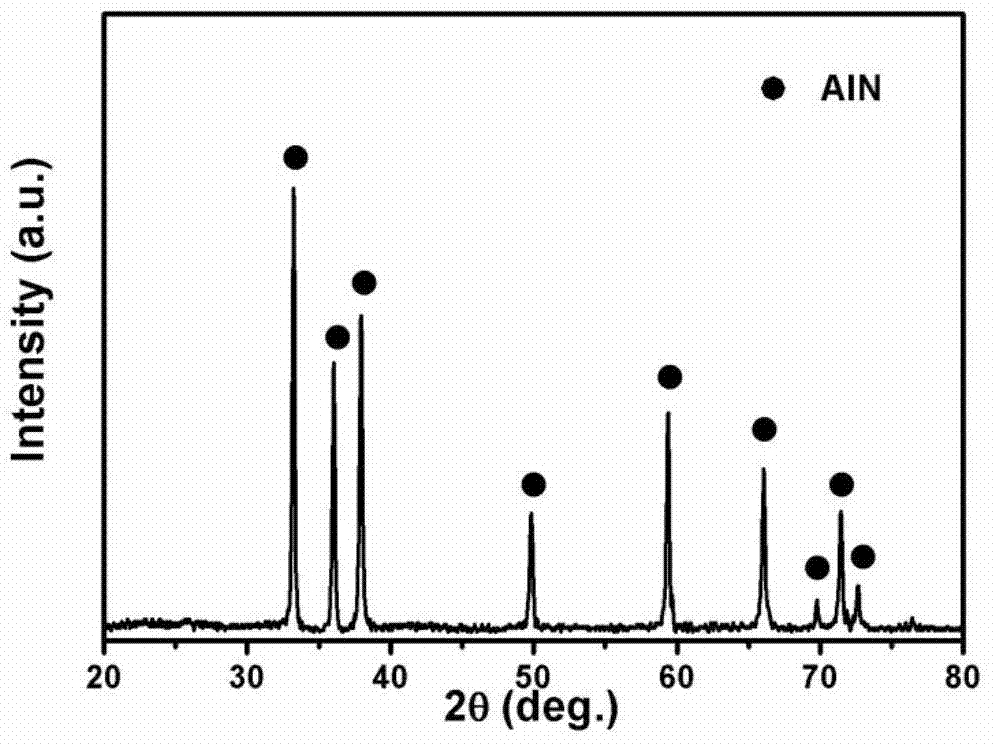

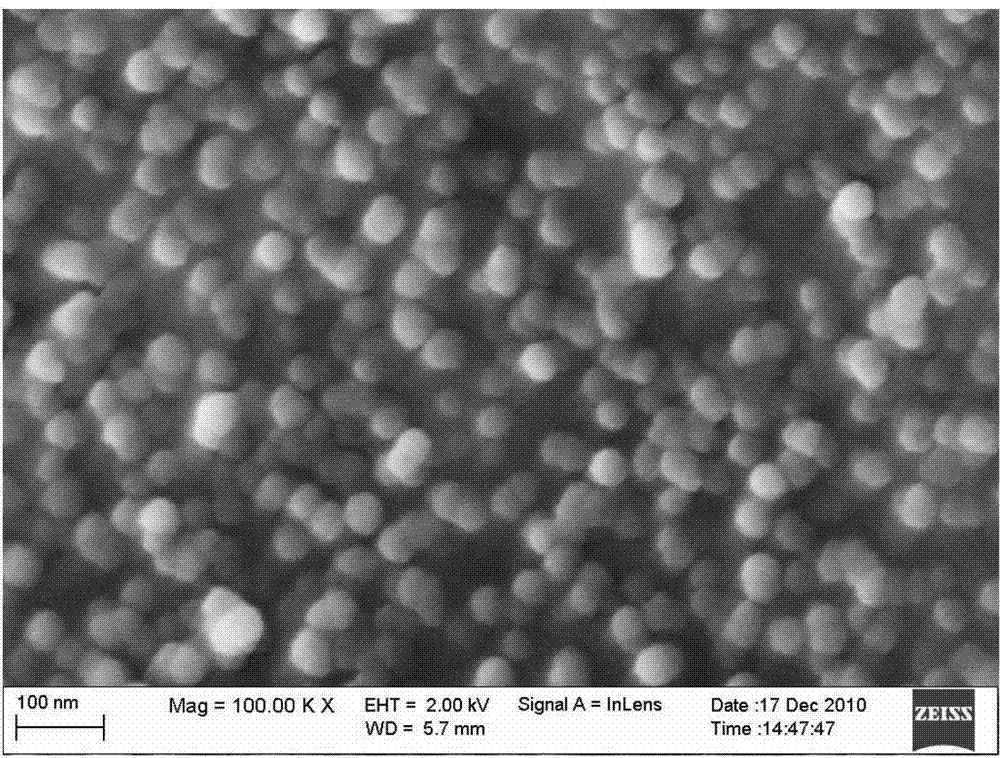

Embodiment 1

[0024] Weigh 0.1 mole of aluminum nitrate, 0.17 mole of glycine, and 0.13 mole of glucose, dissolve various raw materials in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. After the solution undergoes a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained. After the precursor powder is reacted at 1600°C and nitrogen atmosphere for 3 hours, the product is reacted at 700°C and air atmosphere for 2 hours. The nano-aluminum nitride powder with a particle size of about 35-47nm and good sphericity and dispersibility is obtained.

Embodiment 2

[0026] Weigh 0.1 mol of aluminum chloride, 0.3 mol of ammonium nitrate, 0.1 mol of glycine, and 0.13 mol of glucose, dissolve various raw materials in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. After the solution undergoes a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained. After the precursor powder is reacted at 1500°C and nitrogen atmosphere for 2 hours, the product is reacted at 700°C and air atmosphere for 2 hours. The nano-aluminum nitride powder with a particle size of about 33-45nm and good sphericity and dispersibility is obtained.

Embodiment 3

[0028] Weigh 0.1 mol of aluminum chloride, 0.3 mol of ammonium nitrate, 0.05 mol of glycine, and 0.17 mol of glucose, dissolve various raw materials in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. After the solution undergoes a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained. After the precursor powder is reacted at 1450°C and nitrogen atmosphere for 3 hours, the product is reacted at 700°C and air atmosphere for 2 hours. The nano-aluminum nitride powder with a particle size of about 30-42nm and good sphericity and dispersibility is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com