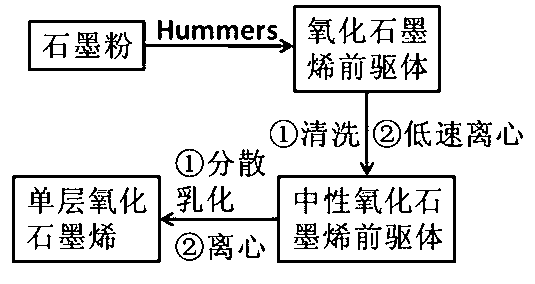

Method for preparing graphene oxide by dispersed emulsion assisted with Hummers method

A dispersed and fossilized technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of large noise pollution, complex operating equipment, unsuitable for industrial application, etc., and achieve the effect of reducing the number of layers and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

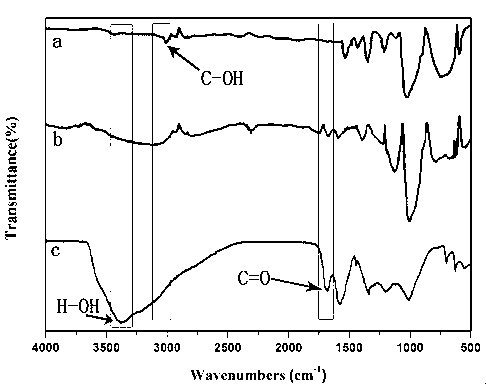

Method used

Image

Examples

Embodiment

[0012] 1. Graphite oxide was prepared by the Hummers method:

[0013] Measure 60 mL of sulfuric acid with a concentration of 98% by mass and pour it into a beaker. Place the beaker in the freezer of the refrigerator and cool it to 0 °C. Weigh 2.5 g of graphite powder and 1.3 g of sodium nitrate and slowly add it to the beaker. Continue mechanical stirring. , slowly add 8g of potassium permanganate, keep the constant temperature at 4°C and continue to react for 1 hour; after the reaction is completed, heat up to 35°C; after 30 minutes, slowly add 150ml of ultrapure water, and continue to heat up to 98°C. At this time, the color of the solution changes from brown Turn into bright yellow; add 500 mL of ultrapure water and 40 mL of 30% H 2 o 2 , to remove unreacted potassium permanganate; then the product obtained was removed by centrifugation at 3000 rpm, and finally the product obtained was filtered, and the filter cake was washed with hydrochloric acid with a mass percentage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com