Antistatic flame-retardation circuit board

A circuit board, anti-static technology, applied in the direction of printed circuit, circuit heating device, printed circuit manufacturing, etc., can solve the problems of unstable sealing performance of circuit board, backward production technology, poor aging resistance, etc., and achieve the promotion of crosslinking And char formation, improve continuity and strength, good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

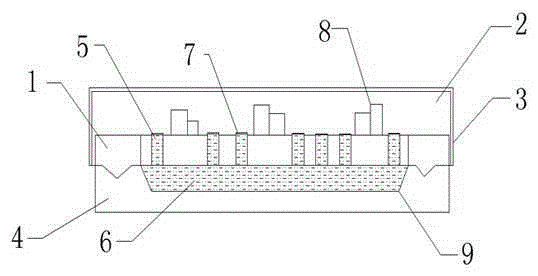

[0037] An anti-static and flame-retardant circuit board, the heat dissipation layer 4 has a thickness of 5mm, the depth of the groove 7 in the heat dissipation layer 4 is 3mm, the diameter of the through hole on the circuit board body 1 is 1mm, and the thickness of the sealing layer 2 exceeds the maximum electronic value of the circuit board. The element height is 2 mm, and the thickness of the protective layer 3 is 0.15 mm. The protective layer is a polytetrafluoroethylene film, and the sealing layer is potting silica gel. The potting silica gel is composed of component A and component B with a weight ratio of 1:1, and component A is composed of the following raw materials in parts by weight: ethylene 40 parts of base resin, 40 parts of silica gel, 2 parts of catalyst, 4 parts of tackifier, 1 part of thickener, 7 parts of solvent, 15 parts of mica, 15 parts of aluminum hydroxide, the B component consists of the following parts by weight Composition of raw materials: 45 parts ...

Embodiment 2

[0052] An anti-static and flame-retardant circuit board, the heat dissipation layer 4 has a thickness of 8mm, the depth of the groove 7 in the heat dissipation layer 4 is 5mm, the diameter of the through hole on the circuit board body 1 is 3mm, and the thickness of the sealing layer exceeds the highest electronic component of the circuit board The height is 5mm, and the thickness of the protective layer is 0.05mm. The protective layer is a polytetrafluoroethylene film, and the sealing layer is potting silica gel. The potting silica gel is composed of component A and component B with a weight ratio of 1:1, and component A is composed of the following raw materials in parts by weight: ethylene 60 parts of base resin, 55 parts of silica gel, 4 parts of catalyst, 7 parts of tackifier, 4 parts of thickener, 15 parts of solvent, 25 parts of mica, 25 parts of aluminum hydroxide, the following parts by weight in the B component Composition of raw materials: 70 parts of vinyl resin, 35...

Embodiment 3

[0067] An anti-static and flame-retardant circuit board, the heat dissipation layer 4 has a thickness of 7mm, the depth of the groove 7 in the heat dissipation layer 4 is 4mm, the diameter of the through hole on the circuit board body 1 is 2.5mm, and the thickness of the sealing layer exceeds the maximum electronic value of the circuit board. The component height is 3mm, and the protective layer thickness is 0.1mm. The protective layer is a polytetrafluoroethylene film, and the sealing layer is potting silica gel. The potting silica gel is composed of component A and component B with a weight ratio of 1:1, and component A is composed of the following raw materials in parts by weight: ethylene 50 parts of base resin, 43 parts of silica gel, 3 parts of catalyst, 6 parts of tackifier, 3 parts of thickener, 10 parts of solvent, 21 parts of mica, 22 parts of aluminum hydroxide, the following parts by weight in the B component Composition of raw materials: 60 parts of vinyl resin, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com