Method for directly producing mineral cotton with hot-melted titanium-containing blast furnace slag

A blast furnace slag and slag wool technology, applied in manufacturing tools, glass manufacturing equipment and other directions, can solve problems such as energy waste and consumption, and achieve the effects of reducing production costs, obvious environmental benefits, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: In this embodiment, the method for producing slag wool with titanium-containing blast furnace slag adopts the following process steps.

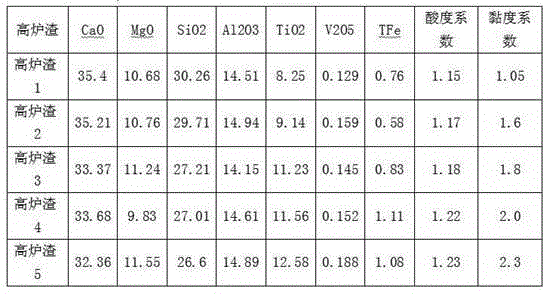

[0027] (1) According to the sampling test of the hot-melt titanium-containing blast furnace slag flowing out of the blast furnace, the test shows that the acidity coefficient = 1.15, the viscosity coefficient = 1.05 Pa·S, and the temperature is 1450 °C; that is, the blast furnace slag 1 in Table 1.

[0028] (2) The hot-melt titanium-containing blast furnace slag is directly introduced into the slag tank, and at the same time, coal gas is injected to carry out heat preservation and homogenization treatment on the hot-melt titanium-containing blast furnace slag in the slag tank. The heat preservation temperature is 1340-1380 °C. The gas used is coke oven gas, or a mixture of blast furnace gas and coke oven gas.

[0029] (3) The treated hot-melt titanium-containing blast furnace slag is introduced into a four-roller centrifu...

Embodiment 2

[0031] Embodiment 2: This embodiment is the same as Embodiment 1 except for the following differences.

[0032] The acidity coefficient of the hot-melt titanium-containing blast furnace slag is 1.17, the viscosity coefficient is 1.6 Pa·S, and the temperature is 1450°C; that is, the blast furnace slag 2 in Table 1.

Embodiment 3

[0033] Embodiment 3: This embodiment is the same as Embodiment 1 except for the following differences.

[0034] The acidity coefficient of the hot-melt titanium-containing blast furnace slag is 1.18, the viscosity coefficient is 1.8 Pa·S, and the temperature is 1450°C; that is, blast furnace slag 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com