Preparation method of flaky alumina

A flaky alumina and aluminum source technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of complex process, long reaction cycle, difficult control of molten salt uniformity, etc., and achieve simple process, low cost, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

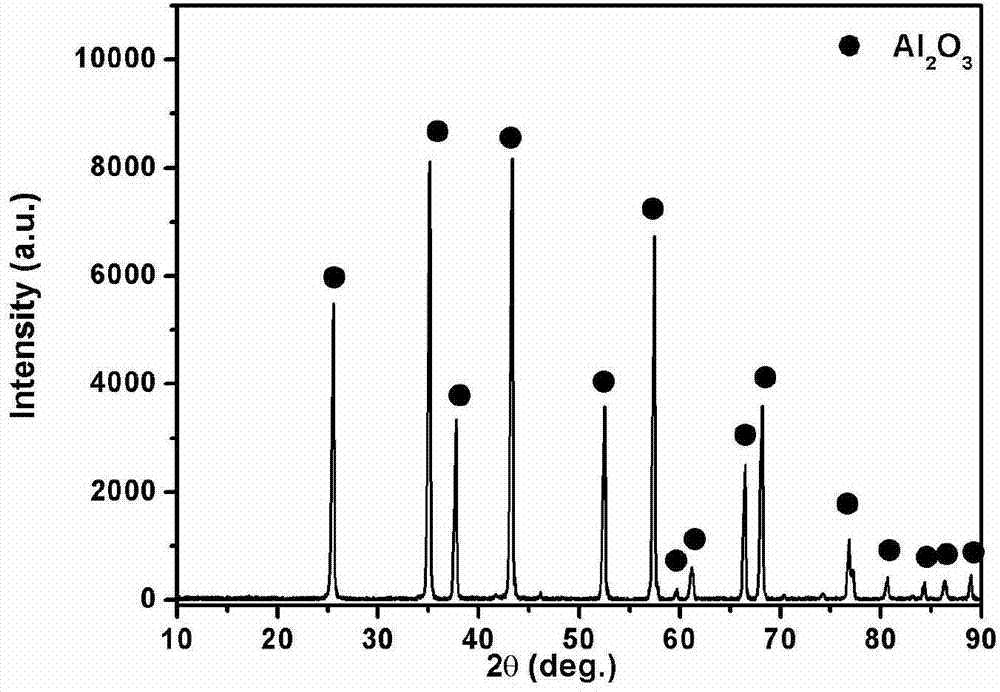

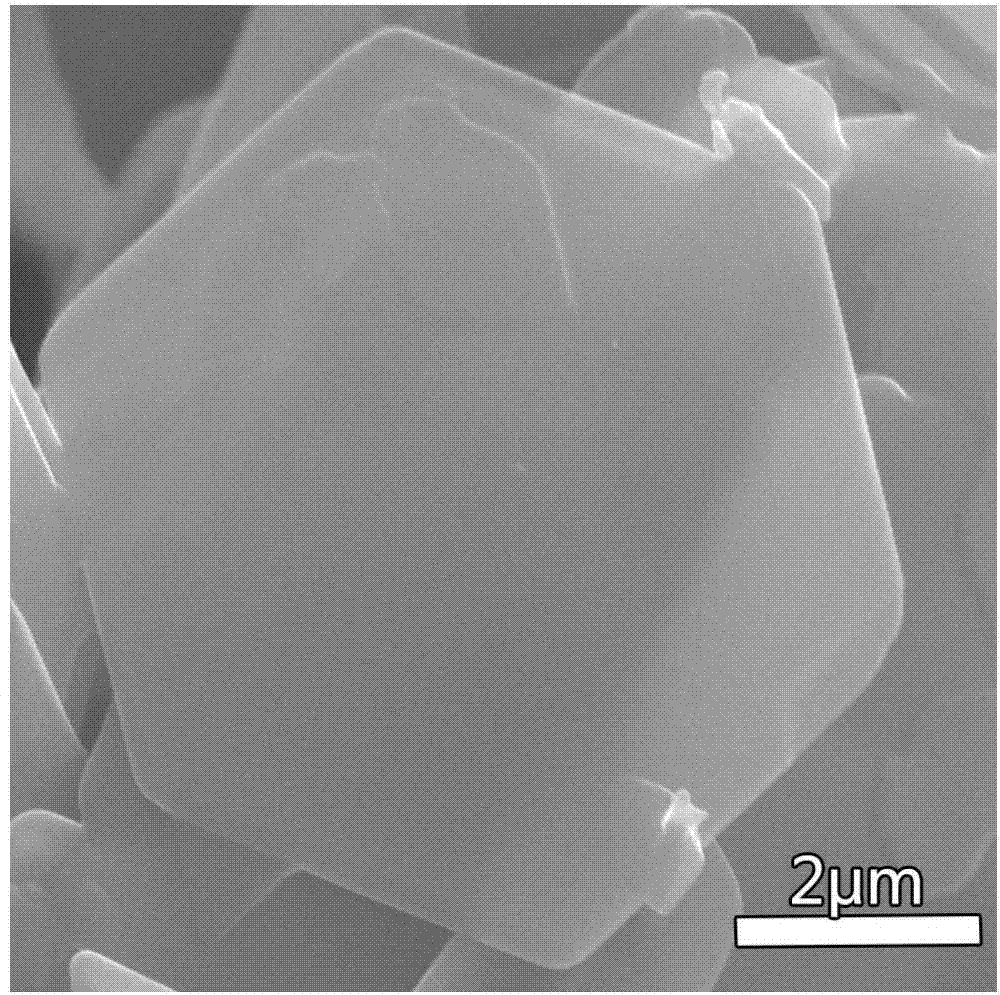

Embodiment 1

[0020] Weigh 0.1 mole of aluminum nitrate, 0.08 mole of urea, and 0.15 mole of sodium fluoride, dissolve various raw materials in distilled water, prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. After the solution undergoes a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained. The precursor powder is reacted for 4 hours at 1300 ° C under the condition of air atmosphere, and the particle size is about 3-6 μm, and the diameter-thickness ratio is about 25-55 flake alumina.

Embodiment 2

[0022] Weigh 0.1 mole of aluminum nitrate, 0.1 mole of urea, 0.1 mole of glucose, and 0.12 mole of sodium fluoride, dissolve various raw materials in distilled water to prepare a solution, and heat the solution on a temperature-controllable electric furnace. After the solution undergoes a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained. The precursor powder is reacted for 3 hours at 1500 ° C under the condition of air atmosphere, and the particle size is about 3-7 μm, and the diameter-thickness ratio is about 25-60 flake alumina.

Embodiment 3

[0024] Weigh 0.1 mole of aluminum nitrate, 0.1 mole of glycine, 0.1 mole of citric acid, and 0.13 mole of sodium fluoride, dissolve various raw materials in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. After the solution undergoes a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained. The precursor powder is reacted at 1650 ° C and air atmosphere for 4 hours, and the particle size is about 3-8 μm, and the diameter-thickness ratio is about 25-65 flake alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com