Electrolyte diaphragm for vanadium cell and preparation method thereof

A technology of electrolyte diaphragm and vanadium battery, which is applied in the field of vanadium batteries, can solve the problems of poor vanadium ion barrier performance, inability to completely prevent vanadium ion penetration, and high cost, and achieve good chemical stability and electrochemical stability, which is beneficial to Effects of battery capacity and enhancement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) 0.5 g of a porous polytetrafluoroethylene film with a thickness of 0.05 mm, a porosity of 50%, a pore diameter of 20 nm, and a number average molecular weight of 200,000 is immersed in 50 g of a solution with a volume ratio of methanol and water of 1:1, Stir and soak at 0°C for 10 hours to obtain a mixed solution I.

[0025] 2) Pour the mixed solution of methanol and ethyl orthosilicate in a molar ratio of 2:1 into the above mixed solution I at 0°C, continue to stir, take the film out of the solution after 10 minutes, and dry it naturally Vacuum dry at 50° C. under a pressure of 0.02 MPa for 10 hours. Then, put the obtained porous polytetrafluoroethylene membrane into a Nafion solution with a mass percent concentration of 1% and soak it for 5 minutes at 0°C, take it out and dry it in the air to obtain PTFE / SiO 2 / Nafion composite membrane is the electrolyte diaphragm for vanadium battery provided by the present invention.

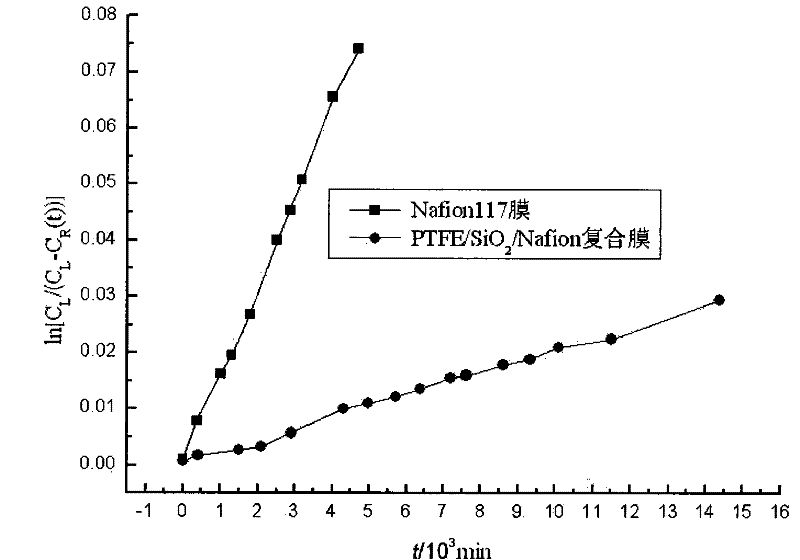

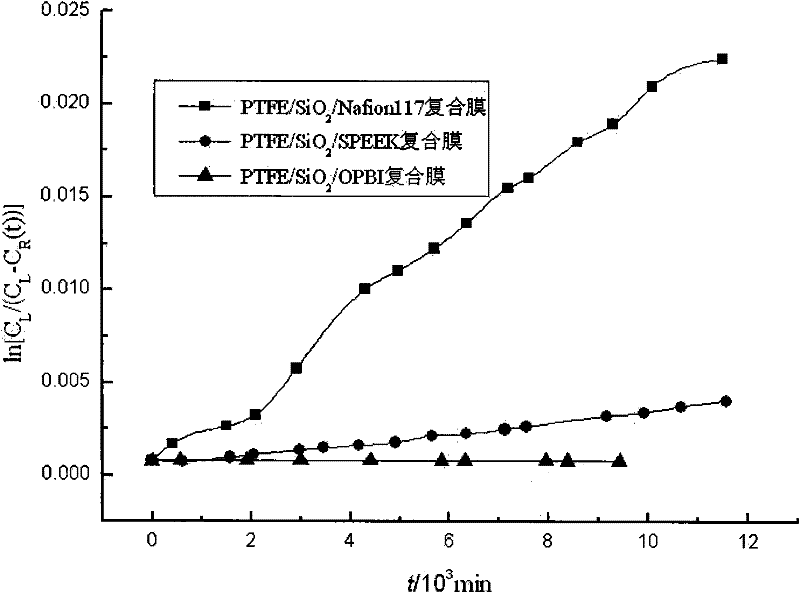

[0026] figure 1 is VOSO 4 On untreated ...

Embodiment 2

[0028] 1) 0.5 g of a porous polytetrafluoroethylene film with a thickness of 0.5 mm, a porosity of 90%, a pore diameter of 500 nm, and a number average molecular weight of 200,000 is immersed in 500 g of a solution with a volume ratio of methanol and water of 10:1, Stir and soak at 50° C. for 24 hours to obtain a mixed solution I.

[0029]2) Pour the mixed solution of methanol and ethyl orthosilicate in a molar ratio of 10:1 into the above mixed solution I at 30°C, continue to stir, take the film out of the solution after 30 minutes, and dry it naturally Vacuum dry at 80° C. under a pressure of 0.08 MPa for 20 hours. Then, put the obtained porous polytetrafluoroethylene membrane into a Nafion solution with a mass percent concentration of 10%, soak it for 30 minutes at 40°C, take it out and dry it in the air to obtain PTFE / SiO 2 / Nafion composite membrane is the electrolyte diaphragm for vanadium battery provided by the present invention.

Embodiment 3

[0031] 1) 0.5 g of a porous polytetrafluoroethylene film with a thickness of 0.1 mm, a porosity of 70%, a pore diameter of 100 nm, and a number average molecular weight of 200,000 is immersed in 250 g of a solution with a volume ratio of methanol and water of 5: 1, Stir and soak at 25°C for 15 hours to obtain a mixed solution I.

[0032] 2) Pour the mixed solution of methanol and ethyl orthosilicate in a molar ratio of 3:1 into the above mixed solution I at 20°C, continue to stir, take the film out of the solution after 15 minutes, and dry it naturally Vacuum dry at 70° C. and 0.05 MPa pressure for 10 hours. Then, put the obtained porous polytetrafluoroethylene membrane into a Nafion solution with a mass percent concentration of 5%, soak it for 10 minutes at 20°C, take it out and dry it in the air to obtain PTFE / SiO 2 / Nafion composite membrane is the electrolyte separator for vanadium battery provided by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com