Method of preparing multiwall carbon nano-tubes/polyvinylidene fluoride porous film material via ultrasonic-assisted phase inversion process

A technology of multi-walled carbon nanotubes and polyvinylidene fluoride, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as limited application, achieve short time consumption and widen application Field, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of multi-walled carbon nanotube / polyvinylidene fluoride porous membrane material, the steps are as follows:

[0027] (1) Preparation of casting solution

[0028] A certain amount of MWCNTs was weighed, and N,N_dimethylformamide (DMF) was used as a solvent, and the MWCNTs were dispersed uniformly by ultrasonication. The polyvinylidene fluoride (PVDF) powder is dried in an oven for a period of time before use to remove moisture. Add PVDF powder into the MWCNT / DMF system to form a casting solution, heat and stir to fully dissolve the PVDF powder to obtain a uniform solution. The resulting casting solution was sealed and allowed to stand at room temperature overnight for degassing.

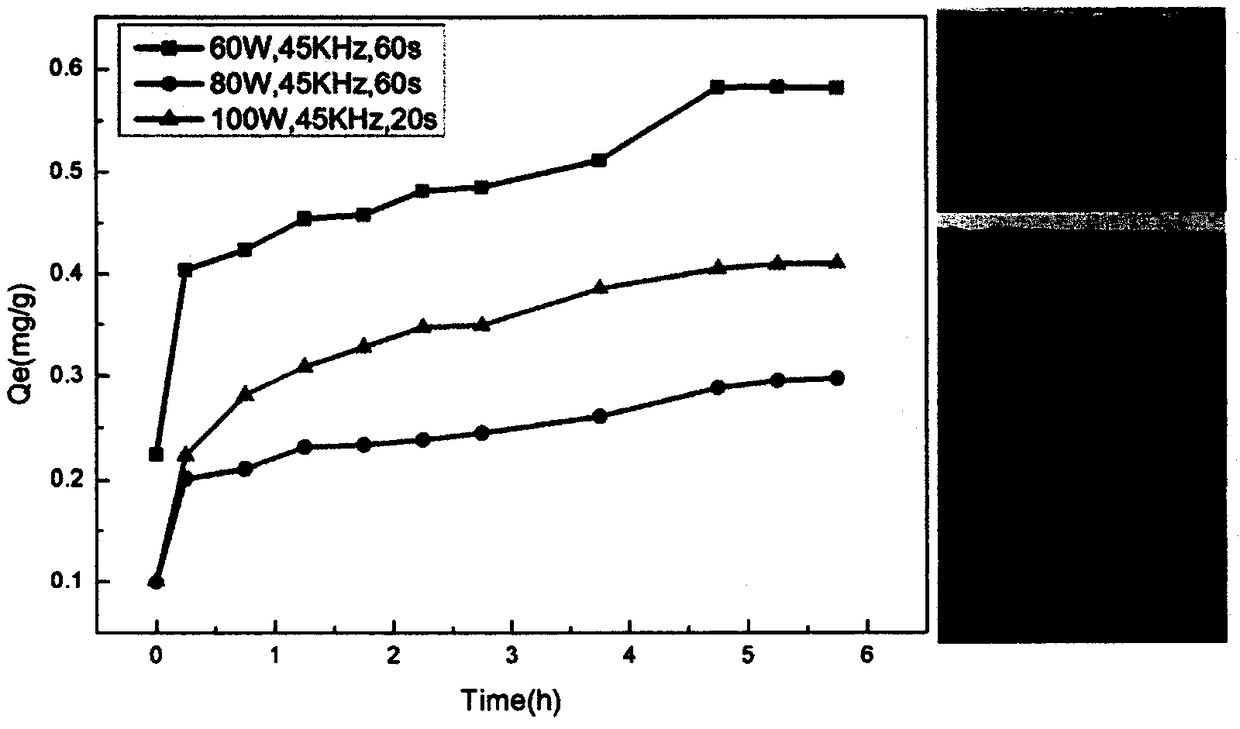

[0029] (2) Preparation of MWCNT / PVDF porous membrane materials by ultrasonic-assisted phase inversion method

[0030] Scrape the film with a scraper on the glass plate, then put the film and the glass plate together into an ultrasonic instrument, and perform ultrasonic treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com