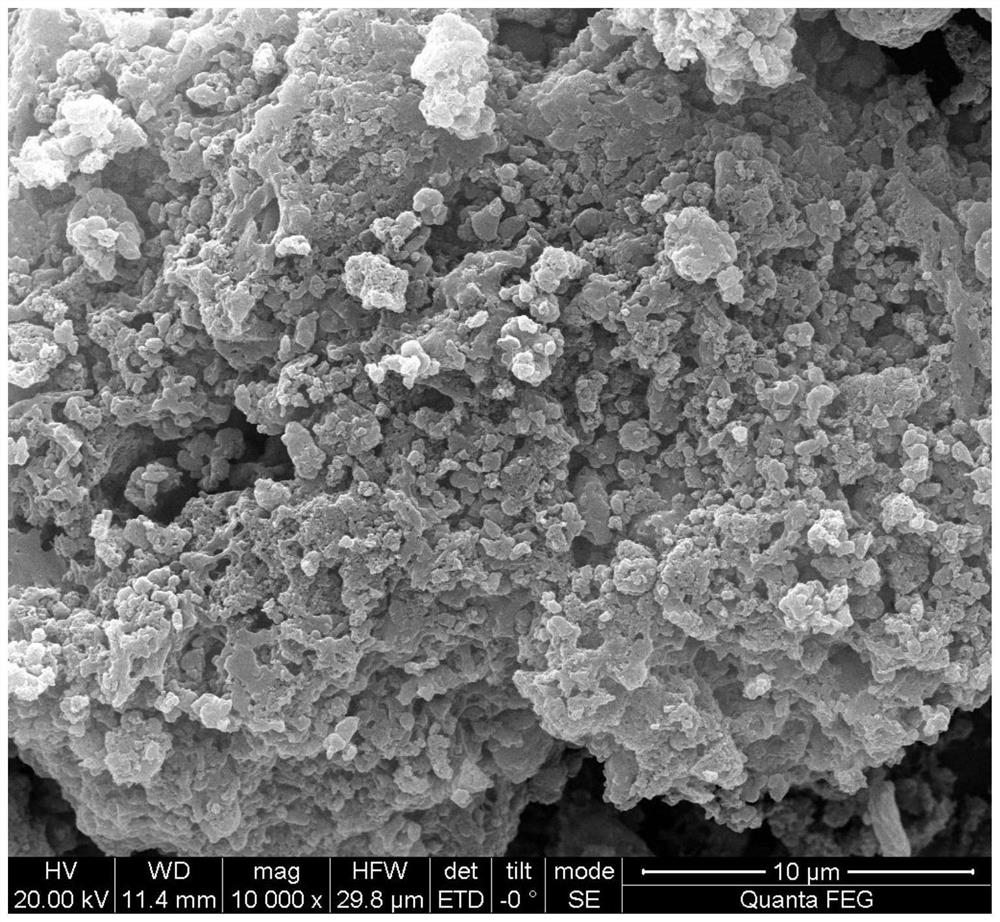

A kind of preparation method of lignin-based mesoporous carbon material

A technology of lignin and carbon materials, applied in chemical instruments and methods, carbon compounds, non-metallic elements, etc., can solve the problems of complex preparation process, unfavorable industrial production, high production cost, etc., and achieve simple preparation process, enhanced stability, The effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

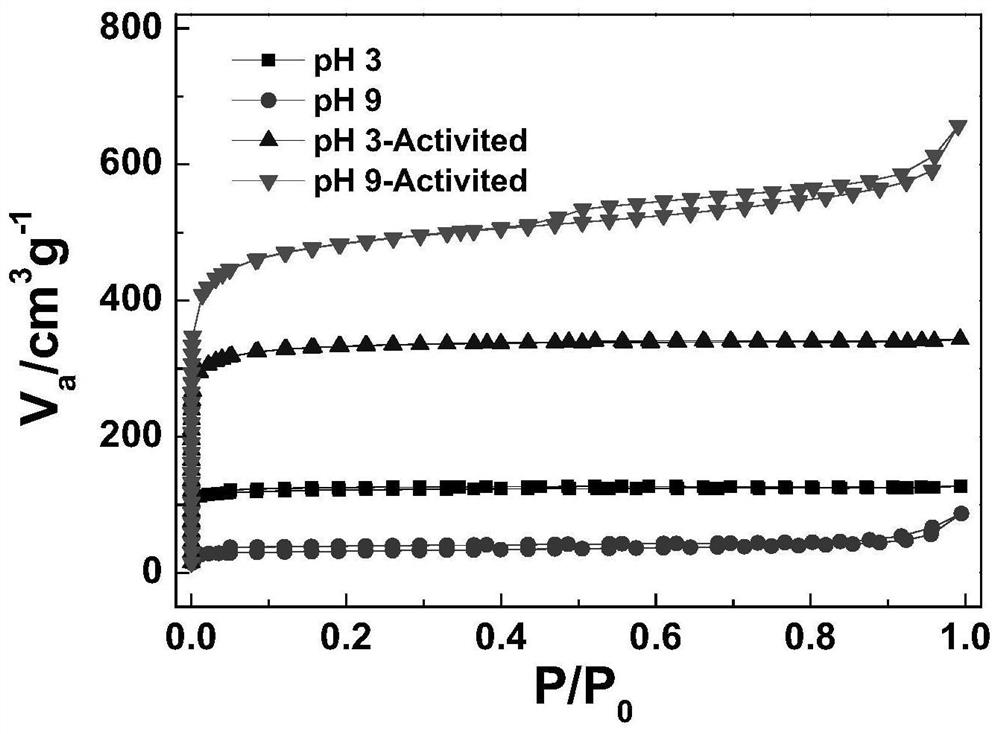

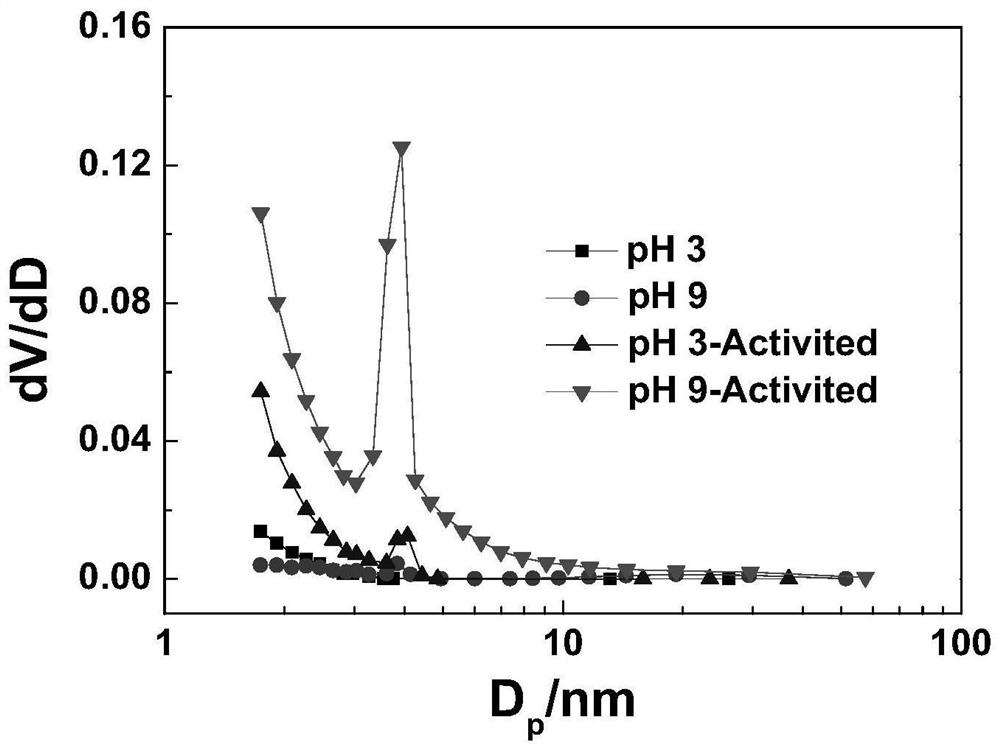

[0024] (1) Preparation of lignin with high silicon content: Take 5g of straw and crush it, add it to 90ml of NaOH solution with a concentration of 0.5mol / L, react for 5h, obtain the reaction solution, adjust the pH to 9 with 0.25mol / L hydrochloric acid, and then settle , 70vt% ethanol washing, low-temperature freeze-drying to obtain lignin with high silicon content;

[0025] (2) Carbonization of lignin: place the high-silicon-content lignin obtained in step (1) in an inert atmosphere furnace, heat up to 1000°C at a heating rate of 20°C / min, and heat-preserve and carbonize for 0.5h;

[0026] (3) Obtaining of mesoporous carbon material: the lignin carbonized in step (2) is mixed with 0.5mol / L potassium hydroxide solution according to the mass volume ratio of 1g:10ml, placed in an inert atmosphere furnace, and heated at 20°C / min Raise the temperature to 1000°C, heat-preserve carbonization reaction for 0.5h; after cooling to room temperature, wash with acidic water and pure water ...

Embodiment 2

[0028] (1) Preparation of lignin with high silicon content: Take 5g of straw and crush it, add it to 75ml of KOH solution with a concentration of 0.5mol / L, react for 5h, obtain the reaction solution, adjust the pH to 7 with 0.25mol / L hydrochloric acid, and then settle , 70vt% ethanol washing, low-temperature freeze-drying to obtain lignin with high silicon content;

[0029] (2) Carbonization of lignin: place the high-silicon-content lignin obtained in step (1) in an inert atmosphere furnace, heat up to 1000°C at a heating rate of 20°C / min, and heat-preserve and carbonize for 0.5h;

[0030] (3) Obtaining mesoporous carbon materials: Mix the carbonized lignin in step (2) with a mass volume ratio of 1:10 and 0.5mol / L potassium hydroxide solution, place it in an inert atmosphere furnace, and heat it at 20°C / min Raise the temperature to 1000°C, heat-preserve carbonization reaction for 0.5h; after cooling to room temperature, wash with acidic water and pure water until neutral, and ...

Embodiment 3

[0032] (1) Preparation of lignin with high silicon content: Take 5g of straw and crush it, add it to 150ml of KOH solution with a concentration of 0.75mol / L, react for 4h, obtain the reaction solution, adjust the pH to 5 with 0.25mol / L hydrochloric acid, and then settle , 70vt% ethanol washing, low-temperature freeze-drying to obtain lignin with high silicon content;

[0033] (2) Carbonization of lignin: place the lignin with high silicon content obtained in step (1) in an inert atmosphere furnace, heat up to 1000° C. at a heating rate of 20° C. / min, and keep warm for carbonization for 3 hours;

[0034] (3) Obtaining of mesoporous carbon material: the lignin carbonized in step (2) is mixed with 0.5mol / L potassium hydroxide solution according to the mass volume ratio of 1g:10ml, placed in an inert atmosphere furnace, and heated at 20°C / min Raise the temperature to 1000°C, heat-preserve carbonization reaction for 0.5h; after cooling to room temperature, wash with acidic water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com