Preparation process of porous carbon nanospheres

A preparation process and technology of nanospheres, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easily destructible carbon precursor self-assembled overall morphology, environmental pollution, etc., to achieve overall Good appearance, less pollution, and convenient for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

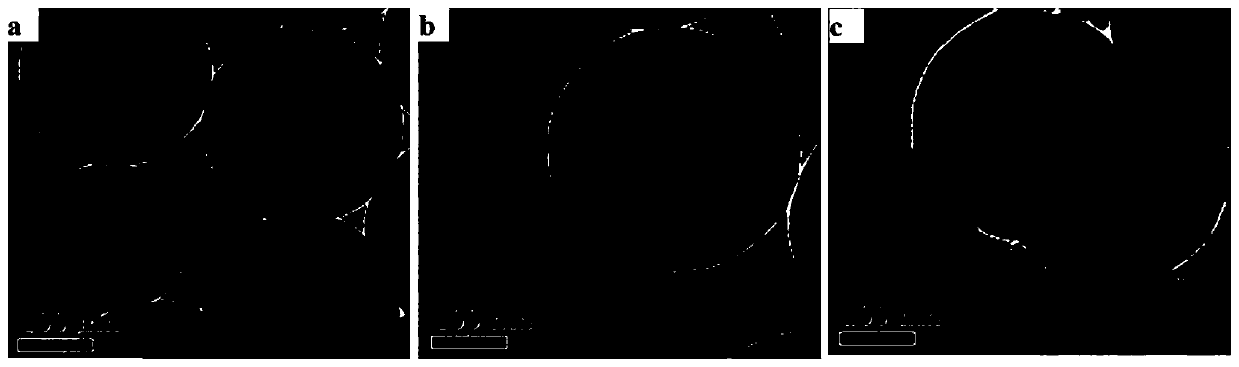

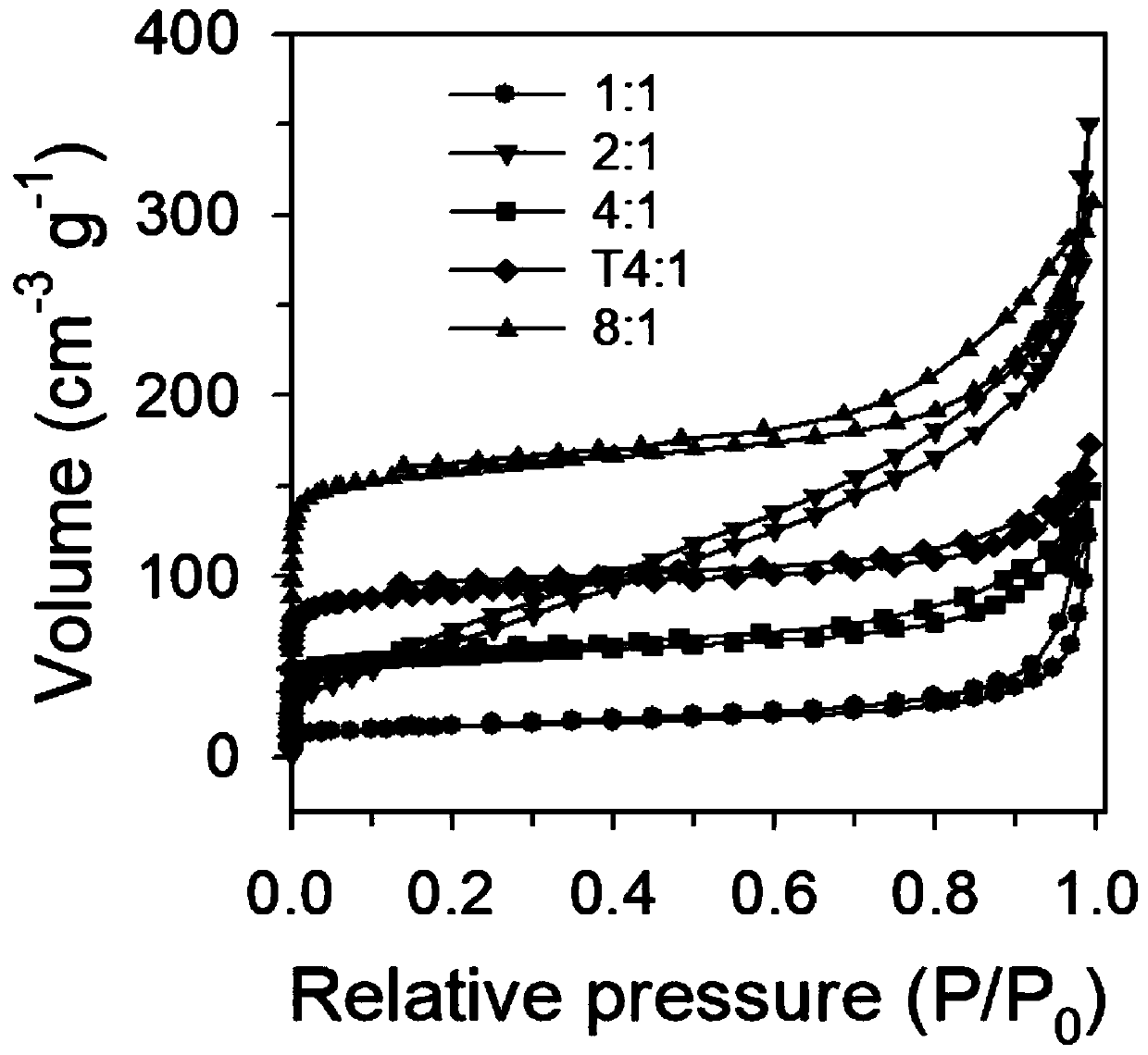

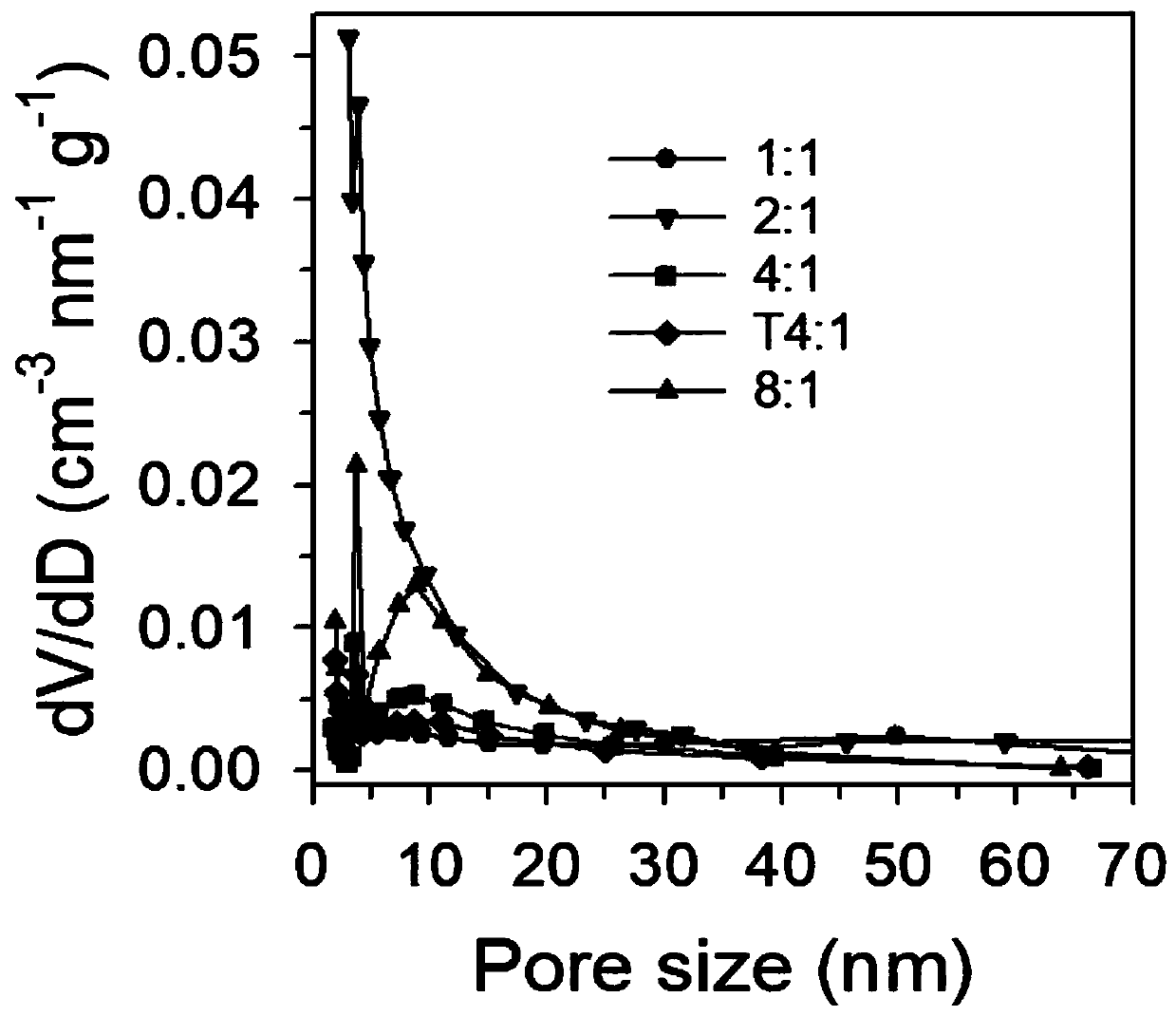

[0035] The embodiment of the present invention provides a preparation process of porous carbon nanospheres, comprising the following steps:

[0036] S1, take 150mg ZnCl 2 The solid was dissolved in 300 mL of deionized water to obtain a ZnCl concentration of 0.5 mg / mL 2 solution;

[0037] S2, to ZnCl 2 Add 150mg 2,6-diaminopyridine to the solution, and stir until completely dissolved (ZnCl 2 The mass ratio of solid to 2,6-diaminopyridine is 1:1);

[0038] S3. Add 225 uL of formaldehyde with a mass percent concentration of 37-40% to the solution obtained in S2, and stir at room temperature for 18 hours until the reaction is complete to obtain solution A;

[0039] S4. Centrifuge the solution A to obtain a centrifuged precipitate, collect the centrifuged precipitate and put it in an oven for drying at 60° C. to obtain a polytriazine;

[0040] S5. Place the polytriazine in a tube furnace, and calcinate it at 600° C. for 5 hours in a nitrogen atmosphere, then raise the temperat...

Embodiment 2

[0043] The embodiment of the present invention provides a preparation process of porous carbon nanospheres, comprising the following steps:

[0044] S1, take 300mg ZnCl 2 The solid was dissolved in 300 mL of deionized water to obtain a ZnCl concentration of 1 mg / mL 2 solution;

[0045] S2, to ZnCl 2 Add 150mg 2,6-diaminopyridine to the solution, and stir until completely dissolved (ZnCl 2 The mass ratio of solid to 2,6-diaminopyridine is 2:1);

[0046] S3. Add 225 uL of formaldehyde with a mass percent concentration of 37-40% to the solution obtained in S2, and stir at room temperature for 18 hours until the reaction is complete to obtain solution A;

[0047] S4. Centrifuge the solution A to obtain a centrifugal precipitate, collect the centrifugal precipitate and put it in an oven for drying at a temperature of 60° C. to obtain a polytriazine;

[0048] S5. Place the polytriazine in a tube furnace, and calcinate it at 600° C. for 5 hours in a nitrogen atmosphere, then rai...

Embodiment 3

[0051]The embodiment of the present invention provides a preparation process of porous carbon nanospheres, comprising the following steps:

[0052] S1, take 600mg ZnCl 2 The solid was dissolved in 300 mL deionized water to obtain a ZnCl concentration of 2 mg / mL 2 solution;

[0053] S2, to ZnCl 2 Add 150mg2,6-diaminopyridine to the solution, and stir until completely dissolved (ZnCl 2 The mass ratio of solid to 2,6-diaminopyridine is 4:1);

[0054] S3. Add 225 uL of formaldehyde with a mass percent concentration of 37-40% to the solution obtained in S2, and stir at room temperature for 18 hours until the reaction is complete to obtain solution A;

[0055] S4. Centrifuge the solution A to obtain a centrifuged precipitate, collect the centrifuged precipitate and put it in an oven for drying at 60° C. to obtain a polytriazine;

[0056] S5. Place the polytriazine in a tube furnace, and calcinate it at 600° C. for 5 hours in a nitrogen atmosphere, then raise the temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com