Preparation method of alumina carrier

A technology of alumina carrier and sodium metaaluminate, which is applied in the direction of catalyst carrier, chemical instrument and method, catalyst activation/preparation, etc., can solve the problem of organic pore-enlarging agent and colloid, uneven distribution of macropores, and complicated preparation process etc. to achieve low cost, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take industrial grade aluminum hydroxide powder and industrial grade sodium hydroxide to configure a concentration of 365g Al 2 o 3 / L concentrated sodium metaaluminate solution, then diluted to a concentration of 25g Al 2 o 3 / L of sodium metaaluminate solution, control the gelling temperature at 29°C, add the condensation product of organic pore-enlarging agent alkylphenol and ethylene oxide (OP-10) and polyoxyethylene sorbitan monooleate ( T-80), wherein the weight ratio of OP-10 and T-80 is 60:40, the amount of organic pore expander accounts for 0.6% of the weight of sodium metaaluminate, diesel oil is used as defoamer, and the amount of defoamer is organic pore expander 0.5% by weight with air and CO 2 The mixed gas, the flow rate is 0.8m 3 / h.(m 3 Sodium metaaluminate solution), where CO 2 The volume fraction of the mixture is 50%, and the mixed gas is used to stir, and the gelation stops when the pH value drops to 10. The slurry was washed with deionized w...

Embodiment 2

[0032] Take industrial grade aluminum hydroxide powder and industrial grade sodium hydroxide to configure a concentration of 365g Al 2 o 3 / L concentrated sodium metaaluminate solution, then diluted to a concentration of 25g Al2 o 3 / L of sodium metaaluminate solution, control the gelling temperature at 29°C, add the condensation product of organic pore-enlarging agent alkylphenol and ethylene oxide (OP-10) and polyoxyethylene sorbitan monooleate ( T-80), wherein the weight ratio of OP-10 and T-80 is 60:40, the amount of organic pore-enlarging agent accounts for 0.6% of the weight of sodium metaaluminate, diesel oil is used as silicone oil, and the amount of silicone oil is 0.7% of the weight of organic pore-enlarging agent , into air and CO 2 The mixed gas, the flow rate is 0.8m 3 / h.(m 3 Sodium metaaluminate solution), where CO 2 The volume fraction of the mixture is 50%, and the mixed gas is used to stir, and the gelation stops when the pH value drops to 10. The slurr...

Embodiment 3

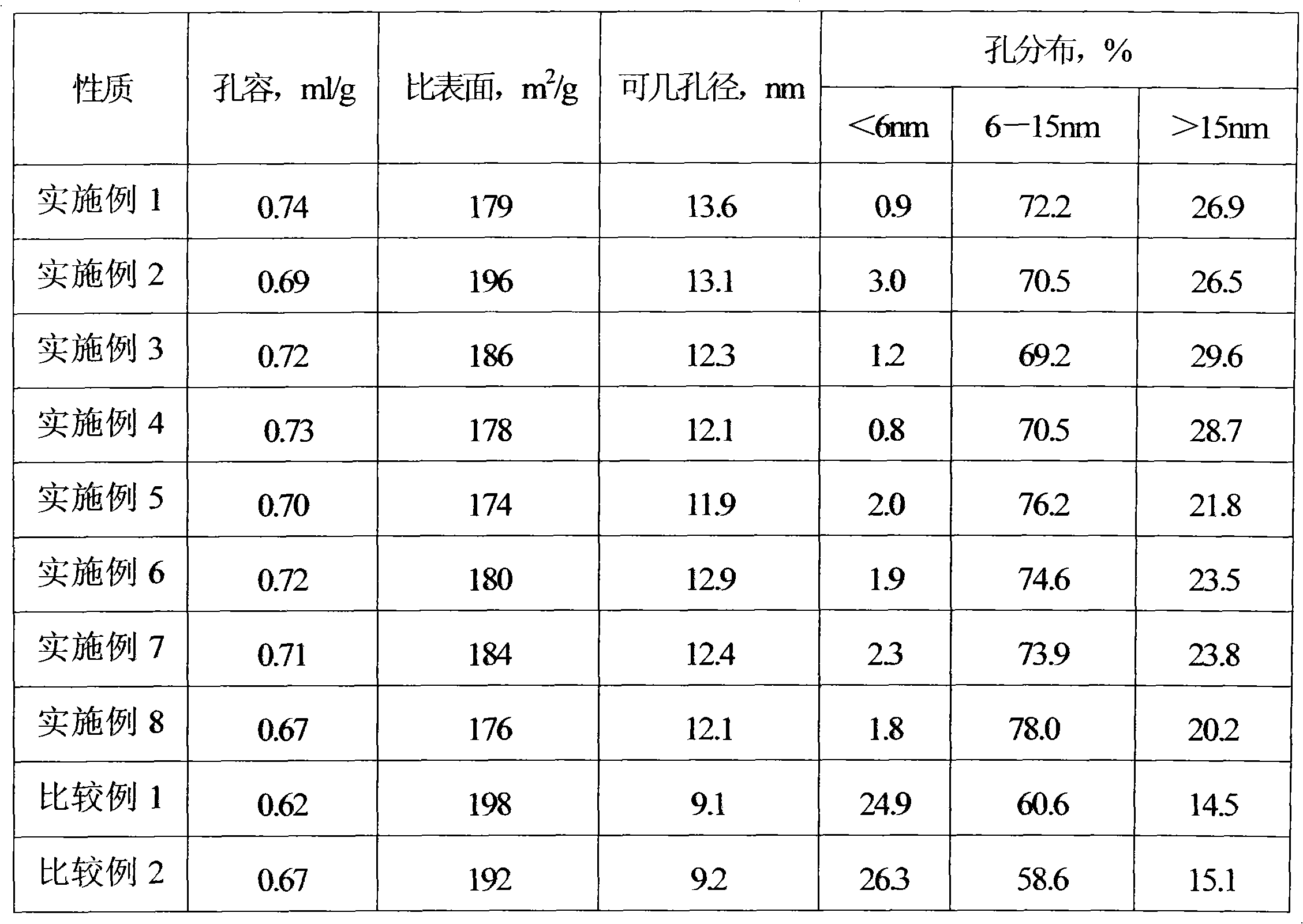

[0034] Same as Example 1, the difference is that the organic pore-enlarging agent OP-10 and T-80 are replaced by OP-12 and T-80, wherein the weight ratio of OP-12 and T-80 is 70: 30, organic pore-enlarging Table 1 shows the physical and chemical properties of the obtained alumina support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com