Preparation method and application of glucose-based porous carbon supercapacitor electrode material

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., to achieve the effects of stable structure, simple preparation process, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

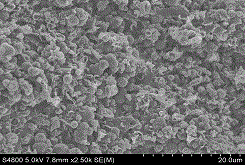

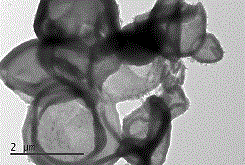

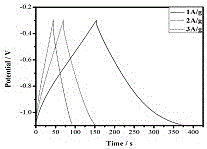

Image

Examples

Embodiment 1

[0031] 8.9g of glucose, 0.188g of thiourea and 0.2g of sodium lauryl sulfate were dissolved in 100ml of distilled water, ultrasonicated for 5min, and then transferred to a polytetrafluoroethylene reactor, at 180 o C hydrothermal reaction 4h; After filtering, washing with distilled water and ethanol three times respectively, then at 40 o Drying at C for 8h to obtain a glucose-based carbon material; the mol ratio of the glucose, thiourea and sodium lauryl sulfate is 20:1:0.28;

[0032] 0.05g of glucose-based carbon material was impregnated in 2.5g of 2wt% KOH solution for 24h, dried, and then heated at 750°C under the protection of argon. o C was activated for 3h, and naturally cooled to room temperature; wherein, the mass ratio of glucose-based carbon material to KOH was 1:1;

[0033] The product obtained above was washed with dilute acid solution, then washed to neutrality with distilled water; o After drying at C for 10 h, the glucose-based porous carbon supercapacitor elec...

Embodiment 2

[0040] Dissolve 8.9g of glucose, 0.188g of thiourea and 0.2g of sodium lauryl sulfate in 100ml of distilled water, the molar ratio of glucose to thiourea is 20:1, sonicate for 5min, and then transfer to a polytetrafluoroethylene reactor , at 180 o C hydrothermal reaction 4h; After filtering, washing with distilled water and ethanol three times respectively, then at 40 oDrying at C for 8h to obtain a glucose-based carbon material; the mol ratio of the glucose, thiourea and sodium lauryl sulfate is 20:1:0.28;

[0041] 0.05g of glucose-based carbon material was impregnated in 5g of 2wt% KOH solution for 24h, dried, and then heated at 750°C under the protection of argon. o C was activated for 3h, and naturally cooled to room temperature; wherein, the mass ratio of glucose-based carbon material to KOH was 0.5:1;

[0042] The product obtained above was washed with dilute acid solution, then washed to neutrality with distilled water; o After drying at C for 10 h, the glucose-based...

Embodiment 3

[0045] Dissolve 8.9g of glucose, 0.188g of thiourea and 0.2g of sodium lauryl sulfate in 100ml of distilled water, the molar ratio of glucose to thiourea is 20:1, sonicate for 5min, and then transfer to a polytetrafluoroethylene reactor , at 180 o C hydrothermal reaction 4h; After filtering, washing with distilled water and ethanol three times respectively, then at 40 o Drying at C for 8h to obtain a glucose-based carbon material; the mol ratio of the glucose, thiourea and sodium lauryl sulfate is 20:1:0.28;

[0046] 0.05g of glucose-based carbon material was impregnated in 1.25g of 2wt% KOH solution for 24h, dried, and then heated at 750°C under the protection of argon. o C was activated for 3h, and naturally cooled to room temperature; wherein, the mass ratio of glucose-based carbon material to KOH was 2:1;

[0047] The product obtained was washed with dilute acid solution, then washed to neutrality with distilled water; o After drying at C for 10 h, the glucose-based por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com