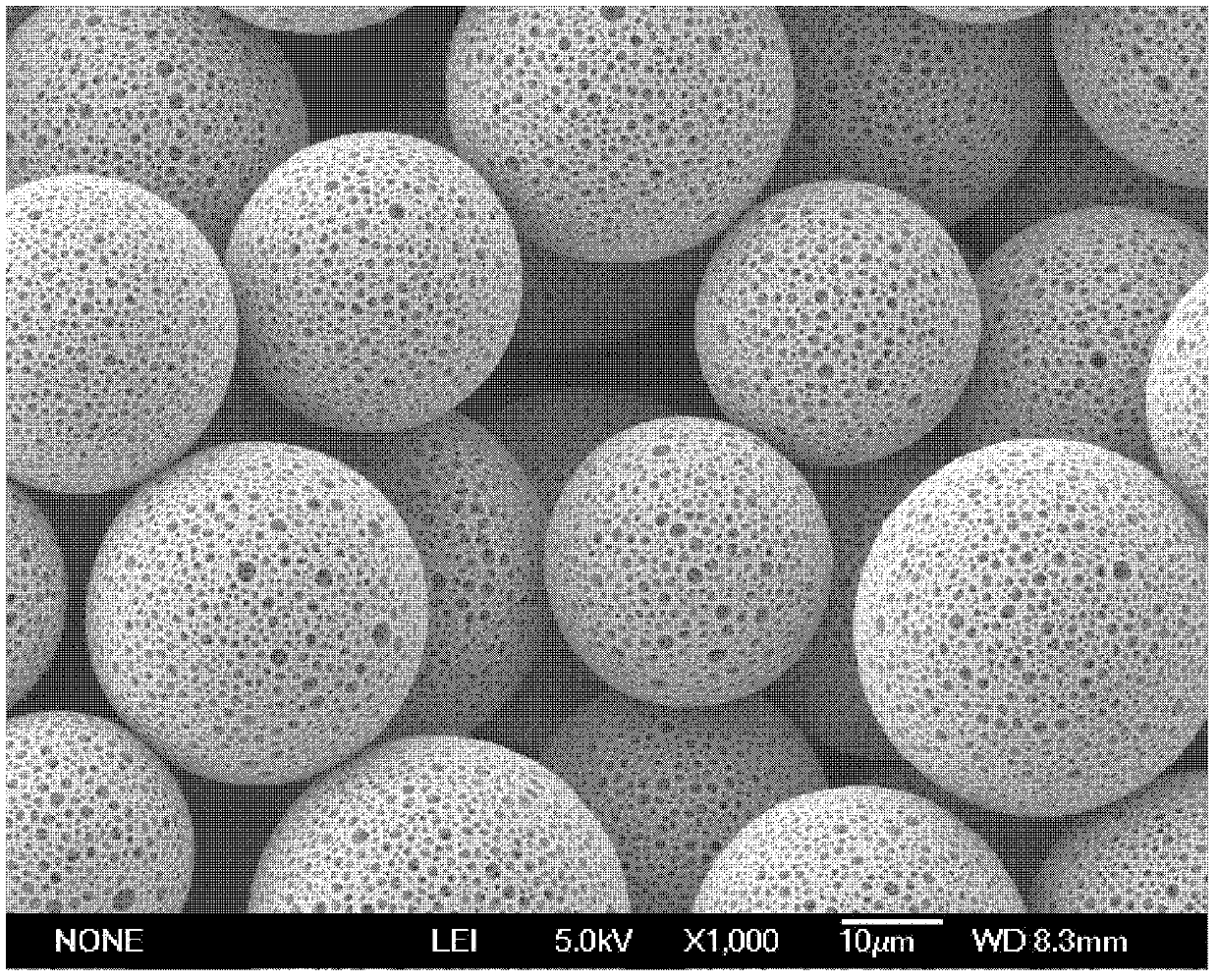

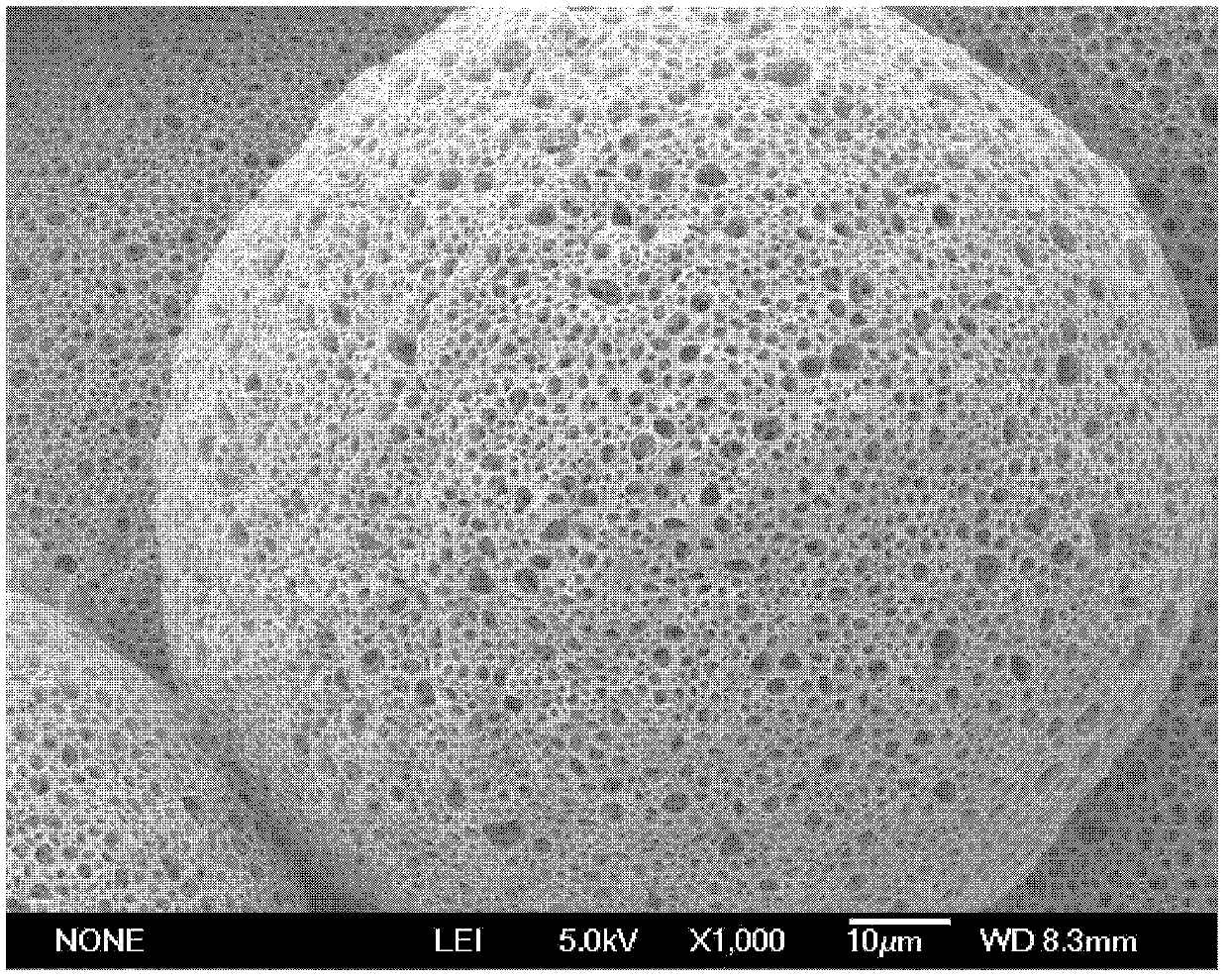

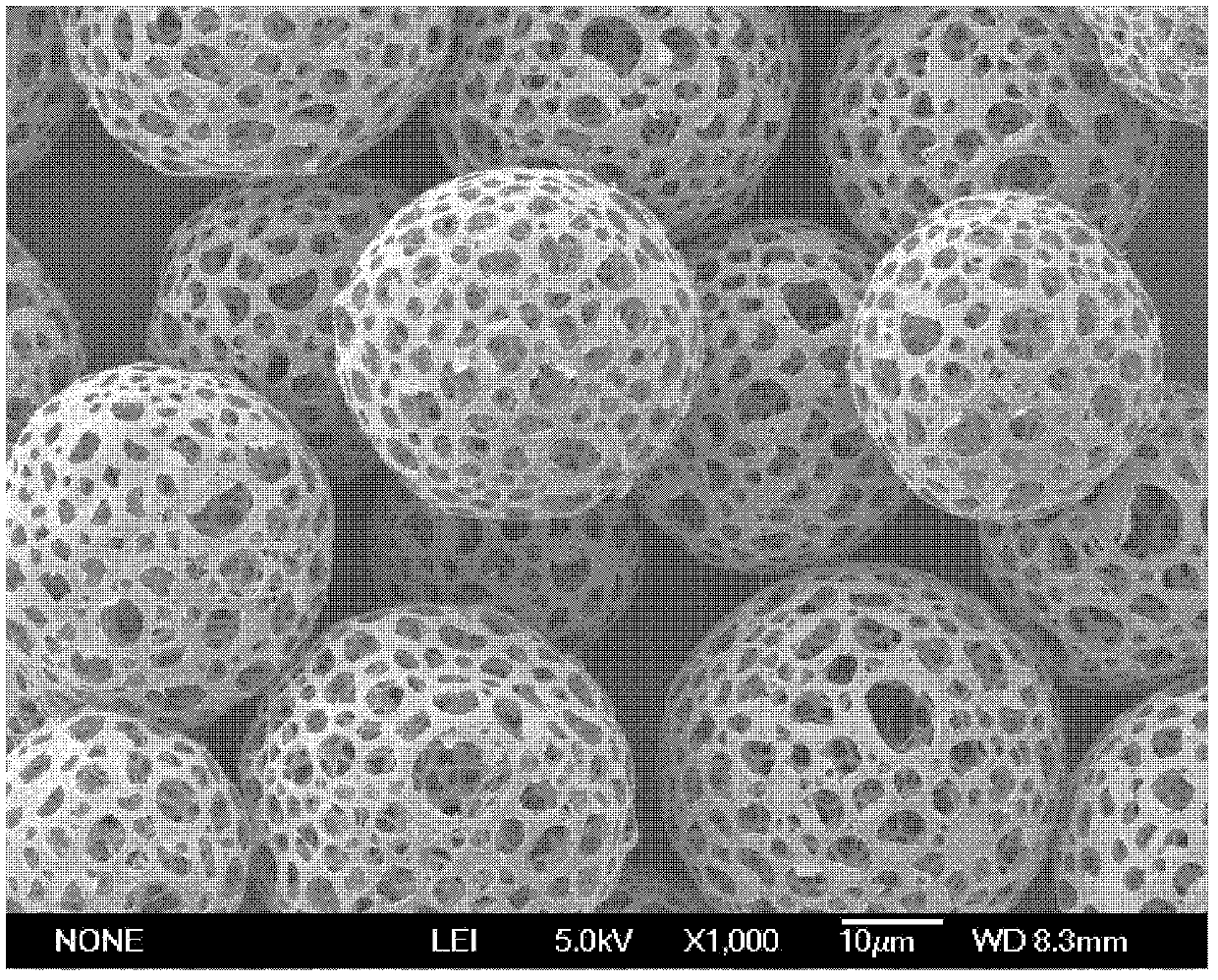

Super macroporous polymer microspheres and preparation method thereof

A polymer, super-porous technology, applied in biochemical equipment and methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of poor product stability, difficulty in large-scale separation and purification, and cumbersome preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] (1) Preparation of primary emulsion:

[0061] Configure a certain concentration of metal ion salt solution as the inner water phase W 1 ; Dissolve a certain mass of linear polymer molecules in a benign organic solvent of the polymer to prepare an oil phase O; pour the inner aqueous phase solution into the oil phase, and emulsify through a homogeneous emulsifier or an ultrasonic cell disruptor to form W 1 / O primary emulsion.

[0062] The linear polymer described in the method includes at least one amphiphilic polymer, such as monomethoxy polyethylene glycol polylactic acid copolymer. In addition to amphiphilic polymers, it also contains one or more other polymers. The polymer molecular chain contains hydroxyl, carboxyl, epoxy, phenyl or chloromethyl, including methyl methacrylate and methacrylic acid Copolymer, polystyrene, polychloromethylstyrene or polybeta-hydroxyethylmethacrylate.

[0063] (2) Preparation of multiple emulsion:

[0064] One or more surfactants a...

Embodiment 1

[0073] Pour 500ml of 0.1% NaCl aqueous solution (W1) into 2L to dissolve 200g of methyl methacrylate and methacrylic acid copolymer P (MMA-MAA) (monomer molar ratio MMA / MAA is 20 / 1) and 8g of monomethyl methacrylate Ethyl acetate (oil phase, O) of oxypolyethylene glycol polylactic acid copolymer (PELA) (the ratio of polylactic acid and polyethylene glycol molecular block is 20 / 1), homogeneously emulsified at 24000rpm for 10min , temperature controlled in an ice-water bath, to obtain W 1 / O primary emulsion. Then the primary emulsion is poured into 25L of 2.5% polyvinyl alcohol (PVA) solution containing 0.01% NaCl, mechanically stirred at 1000rpm for 10min to obtain W 1 / O / W 2 Complex emulsion. After the double emulsion is formed, it is packaged in multiple cylindrical reagent bottles (the ratio of height to diameter is 10 / 1), and a vertical mixer is used to rotate at a constant speed of 60 rpm for 60 minutes, waiting for the aging of the double emulsion droplets. Pour the ...

Embodiment 2

[0076] Pour 500ml of 0.5% NaCl aqueous solution (W1) into 2L to dissolve 200g of methyl methacrylate and methacrylic acid copolymer P (MMA-MAA) (monomer molar ratio MMA / MAA is 20 / 1) and 8g of monomethyl methacrylate Ethyl acetate (oil phase, O) of oxypolyethylene glycol polylactic acid copolymer (PELA) (the ratio of polylactic acid and polyethylene glycol molecular block is 20 / 1), homogeneously emulsified at 24000rpm for 10min , temperature controlled in an ice-water bath, to obtain W 1 / O primary emulsion. Then the primary emulsion is poured into 25L of 2.5% polyvinyl alcohol (PVA) solution containing 0.01% NaCl, mechanically stirred at 1000rpm for 10min to obtain W 1 / O / W 2 Complex emulsion. After the double emulsion is formed, it is packaged in multiple cylindrical reagent bottles (the ratio of height to diameter is 10 / 1), and a vertical mixer is used to rotate at a constant speed of 60 rpm for 60 minutes, waiting for the aging of the double emulsion droplets. Pour the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com