Vacuum concrete mixing process

A vacuum mixing and concrete technology, which is applied in the field of concrete mixing, can solve the problems such as the inability to reduce concrete pores, and achieve the effects of avoiding water evaporation, reducing porosity and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

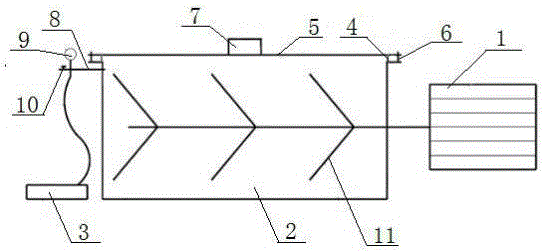

[0034] Such as figure 1 As shown, the present embodiment provides a concrete vacuum mixer, including a motor 1 and a mixing drum 2, the mixing drum 2 is provided with a feed inlet; a sealing cover 5 and a vacuum pump 3 are also included; The mixing drum 2 is connected; the sealing cover 5 seals the feeding port.

[0035] A sealing groove is opened around the feed inlet, and a sealing ring 4 is installed in the sealing groove, and the sealing ring 4 is in contact with the sealing cover 5 .

[0036] A handle 7 is mounted on the sealing cover 5 .

[0037] A testing device is installed on the pipeline 8 , and the testing device includes but not limited to a vacuum gauge 9 .

[0038] The pipeline 8 has three openings, one opening communicates with the inside of the mixing drum 2 , one opening communicates with the vacuum pump 3 , and a valve 10 is installed at one opening.

[0039] The sealing cover 5 is fixed to the mixing drum 2 through fasteners 6 .

[0040] In the vacuum mi...

Embodiment 2

[0042] This embodiment provides a concrete vacuum mixing process, comprising the following steps:

[0043] S1. Prepare mixer, vacuum pump 3, pipeline 8 and sealing cover 5; Described mixer comprises mixing drum 2, has feed inlet on mixing drum 2; Described vacuum pump 3 is communicated with mixing drum 2 through pipeline 8; Said sealing The cover 5 seals the feed port; the pipeline has three openings, one opening communicates with the inside of the mixing drum, one opening communicates with the vacuum pump, and one opening is equipped with a valve; the sealing cover 5 is connected to the The mixing drum 2 is fixed.

[0044] S2. Add raw materials to the mixing drum 2 of the mixer;

[0045] S3. close the valve, and seal the feeding port of the mixing drum 2 with the sealing cover 5;

[0046] S4. Start the vacuum pump 3 to evacuate the inside of the mixing drum 2;

[0047] S5. stop vacuuming, start the mixer to mix the concrete;

[0048] S6. stop stirring, slowly open valve 1...

Embodiment 3

[0057] The difference between this embodiment and embodiment 2 is that the raw material does not include a water reducing agent, but a vacuum gauge 9 is installed on the pipeline to measure the air pressure in the mixing drum, and vacuum is drawn to the mixing drum 2 according to step S4 The air pressure inside is A; when the air pressure is A, the boiling point of water is B; B is greater than the temperature outside the mixing drum. In this example, the ambient temperature is 25°C, the air pressure A is 5kPa, and when the air pressure A is 5kPa, the boiling point of water is 32.9°C, and the ambient temperature is lower than the boiling point of the water in the mixing drum. Under normal stirring conditions, the moisture in the concrete will not evaporation. By controlling the minimum air pressure in the mixing drum, the porosity can be significantly reduced by only vacuuming without using a water reducer. In this embodiment, by adjusting the vacuum degree and mixing time in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com