Hydrofining catalyst carrier and preparation method thereof as well as hydrofining catalyst using carrier and preparation method of hydrofining catalyst

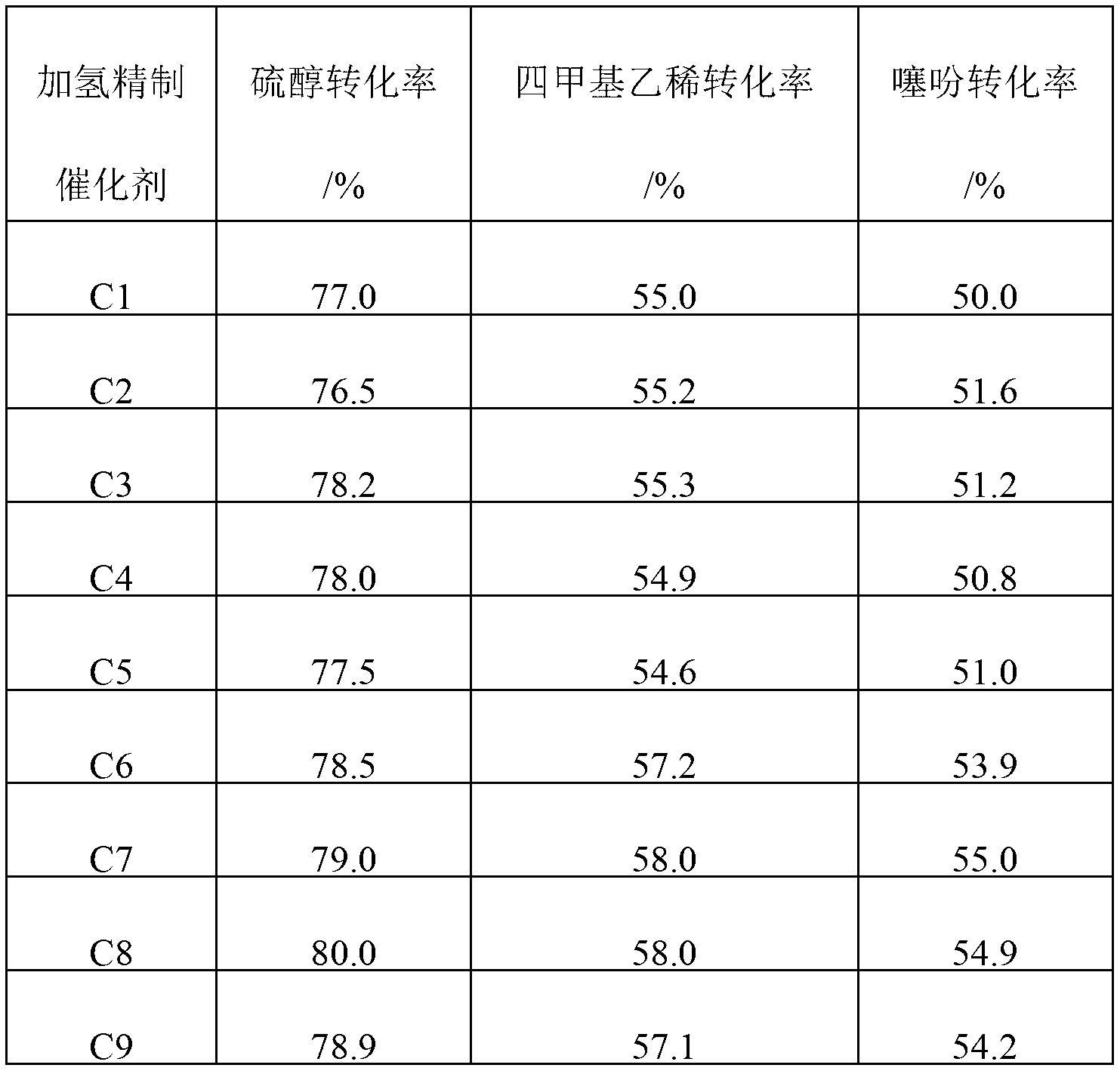

A catalyst carrier, hydrorefining technology, applied in catalyst carriers, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of reducing active component loading, reducing carrier adsorption activity, affecting Catalytic activity and catalytic reaction efficiency of catalysts, to achieve the effect of improving catalytic performance, good molding, and increasing adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

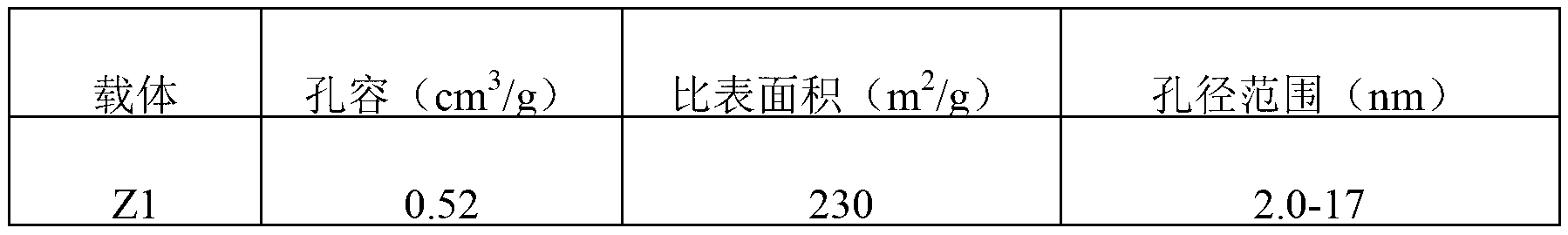

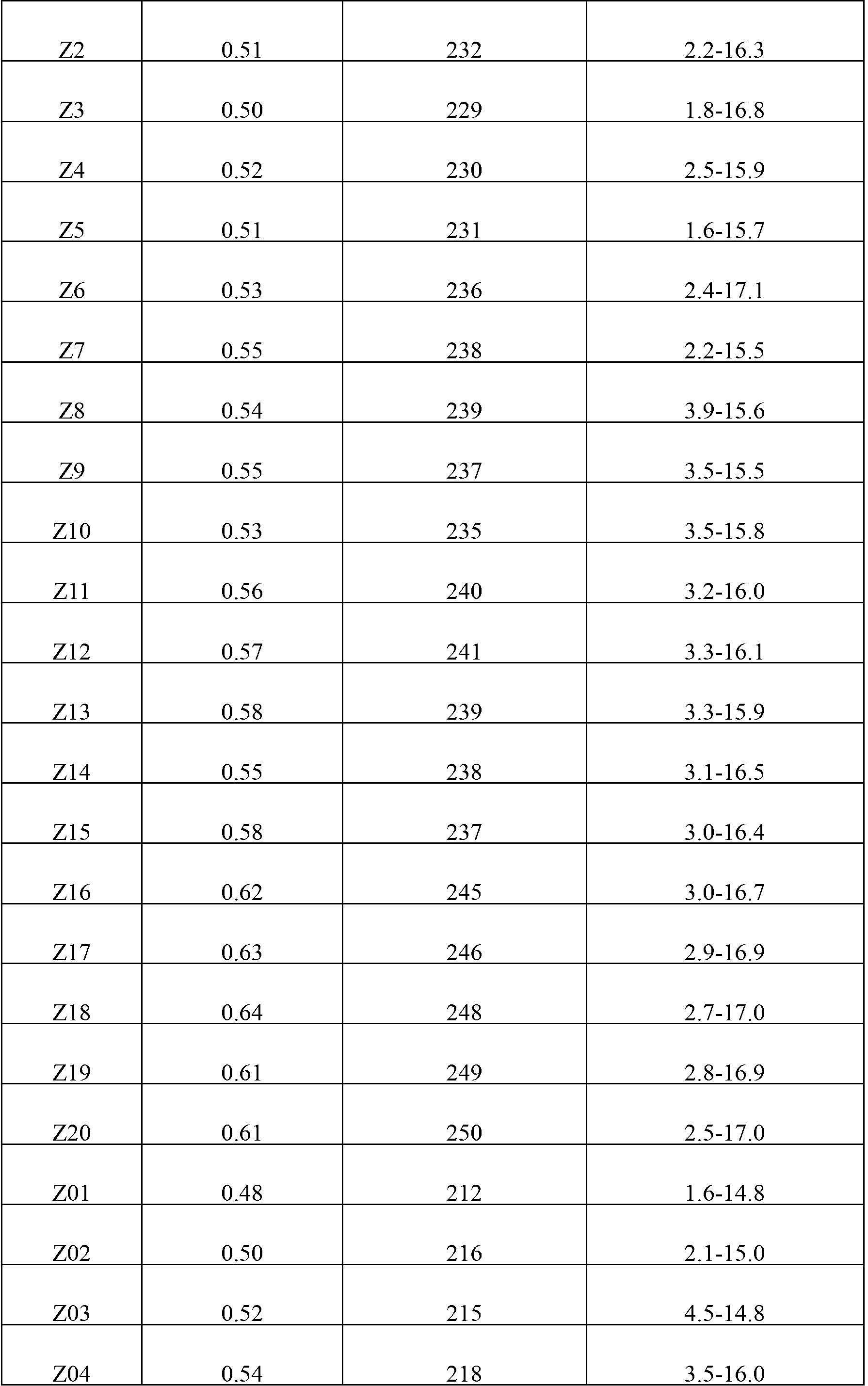

Embodiment 1

[0036] (1) Add 300g of diatomaceous earth to 300g of 10wt% sodium hydroxide solution and soak for 2 hours, then directly add 10wt% of nitric acid solution to neutralize, then rinse with deionized water and press filter, the obtained filter cake is modified Diatomite, the pore volume of the modified diatomite is 1.05cm 3 / g, the specific surface area is 380m 2 / g;

[0037] (2) Add 250 g of deionized water to 200 g of modified diatomite and stir evenly to obtain a premix;

[0038] (3) Mix 600g of nano-alumina powder and 400g of the premix and put it into an extruder to extrude into strips of Φ1х4cm, dry the strips at 95°C for 1h, and roast at 350°C for 2h to obtain carrier Z1 .

Embodiment 2

[0040] (1) Add 400g of diatomaceous earth to 600g of 12wt% potassium hydroxide solution and soak for 3 hours, then directly add 10wt% formic acid solution to neutralize, then rinse with deionized water and press filter, and the obtained filter cake is modified Diatomite, the pore volume of the modified diatomite is 1.10cm 3 / g, the specific surface area is 400m 2 / g;

[0041] (2) Add 300g of nitric acid solution to 300g of modified diatomite and stir evenly to obtain a premix;

[0042] (3) Mix 500g of nano-alumina powder and 500g of the premix, put them into an extruder and extrude them into strips of Φ1х4cm, dry the strips at 100°C for 3h, and roast at 450°C for 2h to obtain carrier Z2 .

Embodiment 3

[0044] (1) Add 300g of diatomaceous earth to 600g of 15wt% sodium carbonate solution and soak for 4 hours, then directly add 10wt% of oxalic acid solution to neutralize, then rinse with deionized water and press filter, the obtained filter cake is modified silicon Alite, the pore volume of the modified diatomite is 1.20cm 3 / g, the specific surface area is 430m 2 / g;

[0045] (2) Add 200g of citric acid to 260g of modified diatomite and stir evenly to obtain a premix;

[0046] (3) Mix 500g of nano-alumina powder and 400g of the premix, put them into an extruder and extrude them into strips of Φ1х4cm, dry the strips at 110°C for 3h, and roast at 400°C for 3h to obtain carrier Z3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com