Preparation method of graphene sponge material used for air purification

A graphene sponge and air purification technology, which is applied in the field of graphene sponge material for air purification and its preparation, can solve problems such as restacking, and achieve the effects of easy operation, low cost, good mechanical properties and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

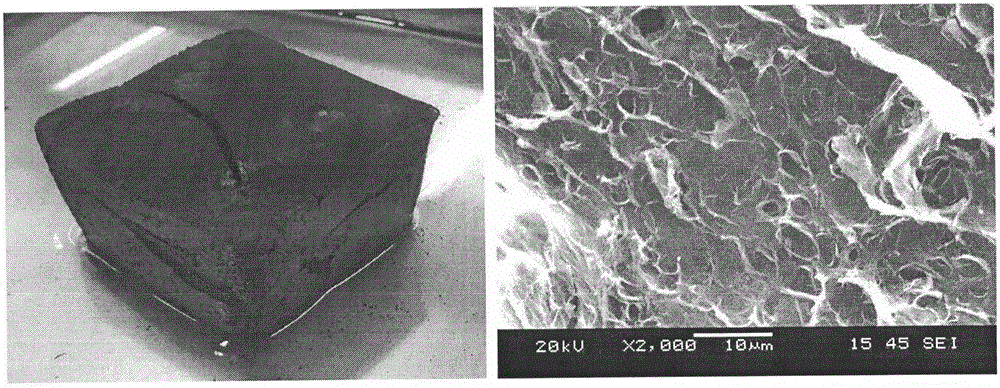

[0029] Embodiment 1 prepares graphene sponge

[0030] 1) 25kHz ultrasonic treatment of graphene oxide and carbon nanotubes to prepare a mixed aqueous solution for 40min; the mass ratio of graphene oxide and carbon nanotubes is 5:1

[0031] 2) Transfer the solution obtained in step 1) into a reaction kettle, heat it to 180° C. for 12 hours, and then cool it naturally; freeze-dry it to obtain a graphene sponge.

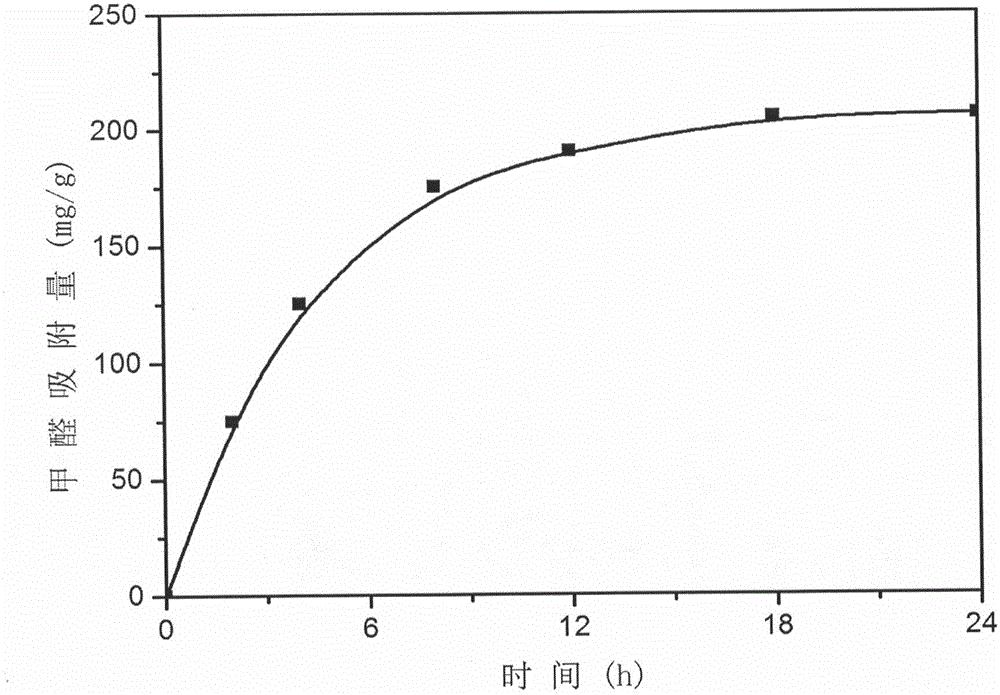

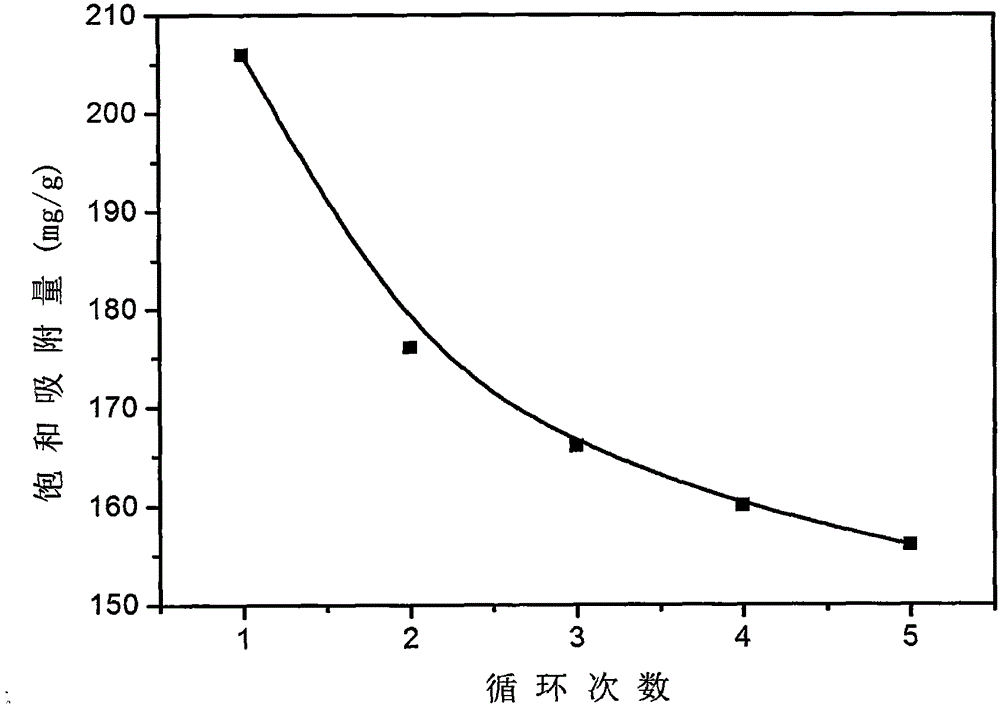

[0032] After testing, it was found that the adsorption capacity of this graphene sponge to formaldehyde was 205mg / g.

Embodiment 2

[0033] Embodiment 2 prepares graphene sponge

[0034] 1) 25kHz ultrasonic treatment of graphene oxide and carbon nanotubes to form a mixed aqueous solution for 30 minutes; the mass ratio of graphene oxide and carbon nanotubes is 10:1

[0035] 2) Transfer the solution obtained in step 1) into a reaction kettle, heat to 200°C for 10 hours, and then cool naturally; freeze-dry at -50°C and vacuum <10Pa for 3 days to obtain a graphene sponge.

[0036] After testing, it was found that the adsorption capacity of this graphene sponge to ammonia gas was 100mg / g.

Embodiment 3

[0037] Embodiment 3 prepares graphene sponge

[0038] 1) Ultrasonic treatment of graphene oxide and carbon nanotubes to form a mixed aqueous solution for 20 minutes; the mass ratio of graphene oxide and carbon nanotubes is 7:1

[0039] 2) Transfer the solution obtained in step 1) into a reaction kettle, heat to 190° C.) and keep the temperature for 11 hours, then cool naturally; freeze-dry to obtain a graphene sponge.

[0040] After testing, it was found that the adsorption capacity of this graphene sponge to nitric oxide was 136mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com