Upper roller cover and fiber guide belt with nanometer granules

A fiber and apron technology, applied in the field of upper cover rollers and fiber guide aprons, can solve the problems of high fluctuation friction state, short service life, material damage, etc., and achieve the improvement of friction state, reduction of times and improvement of yarn quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

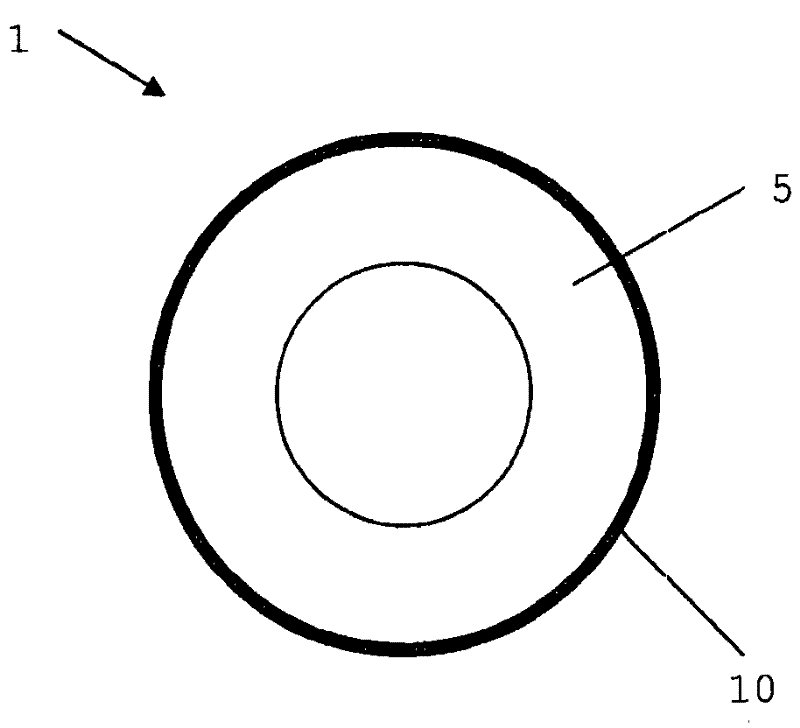

[0033] figure 1 A top sheath roller 1 is shown in section, such as is typically used in spinning machine drafting arrangements. The upper sheathing roller has a substantially cylindrical core 5 comprising plastic. The skin layer 10 is arranged on the core 5 . In the illustrated embodiment, the skin layer 10 is arranged to cover the entire area. The structure of the entire area makes it possible to have a simple coating process. However, partial coating structures of the sheath layer are also possible, for example at locations on the upper sheathing roller which are subjected to specific mechanical loads.

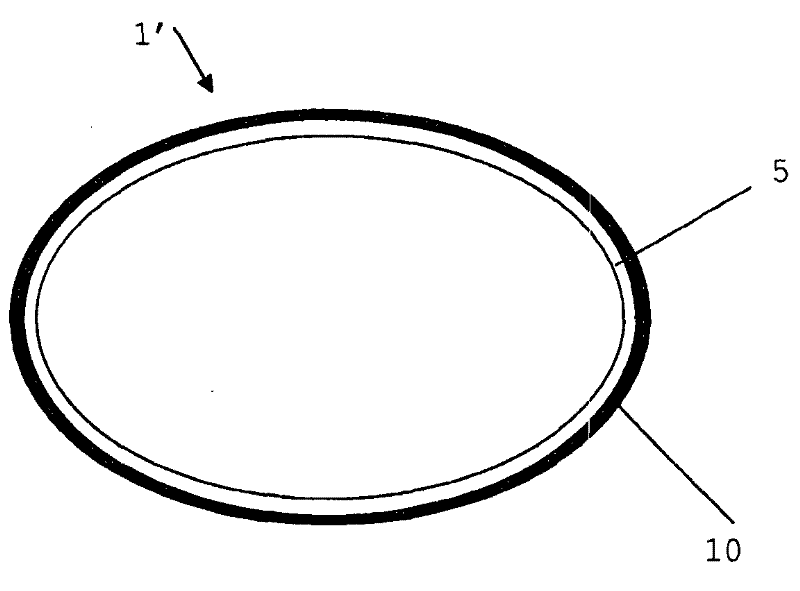

[0034] figure 2 The fiber guiding apron 1' is shown in section. In the present case the section shown is elliptical, but it can also take other forms, depending on how the fiber guiding apron is guided in the drafting configuration. The fiber guiding apron 1' has a core 5 comprising plastic, on which a sheath layer 10 is arranged to cover the entire area.

[0035] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com