Preparation method of epitaxial lanthanum strontium cobalt oxide film based on radio-frequency reactive sputtering

A technology of lanthanum strontium cobalt oxide and magnetron sputtering coating, which is applied in the field of radio frequency reactive sputtering epitaxial lanthanum strontium cobalt oxide thin film preparation, can solve the problems of few thin film reports, high cost, harshness, etc., and achieve simple doping method Fast, high target utilization rate, avoiding the effect of impurity phase formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

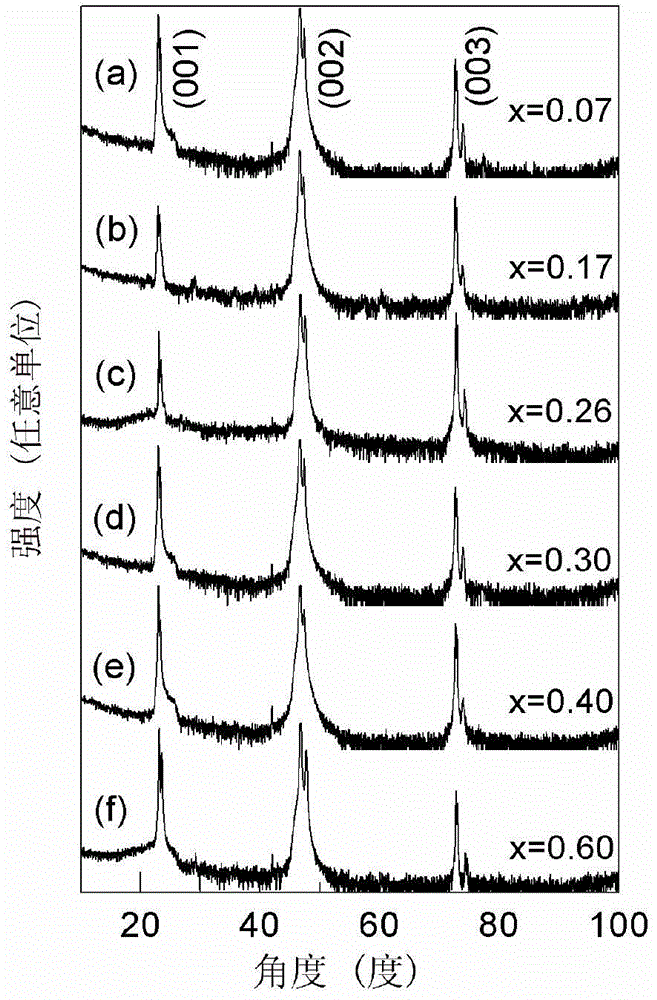

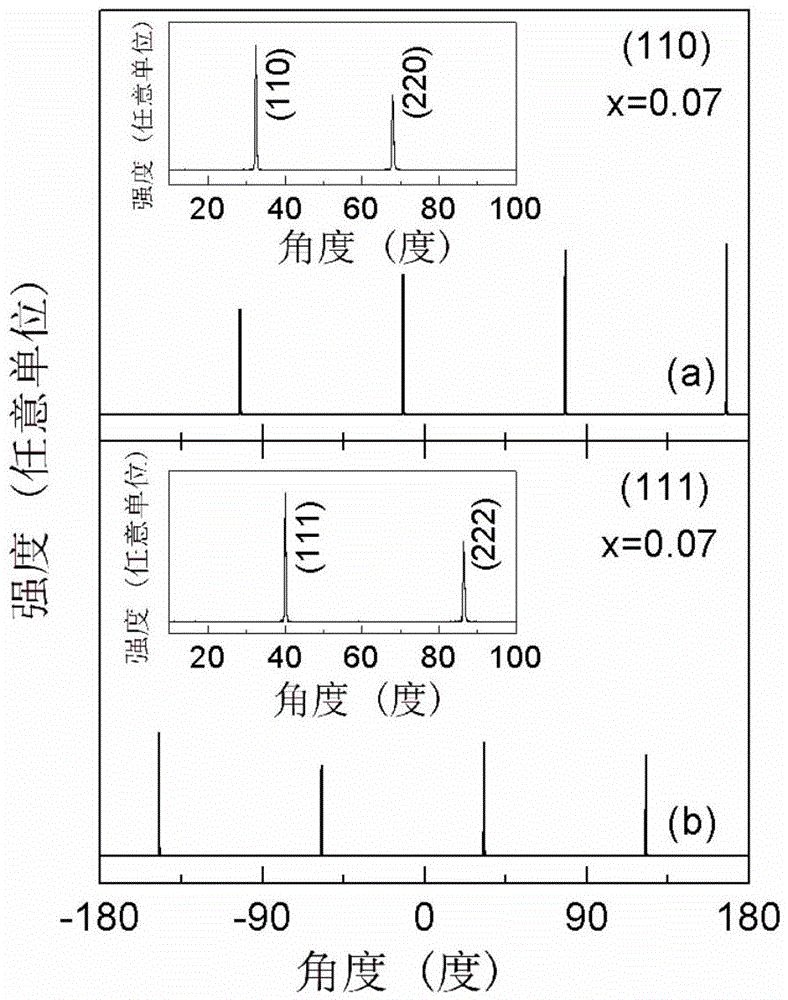

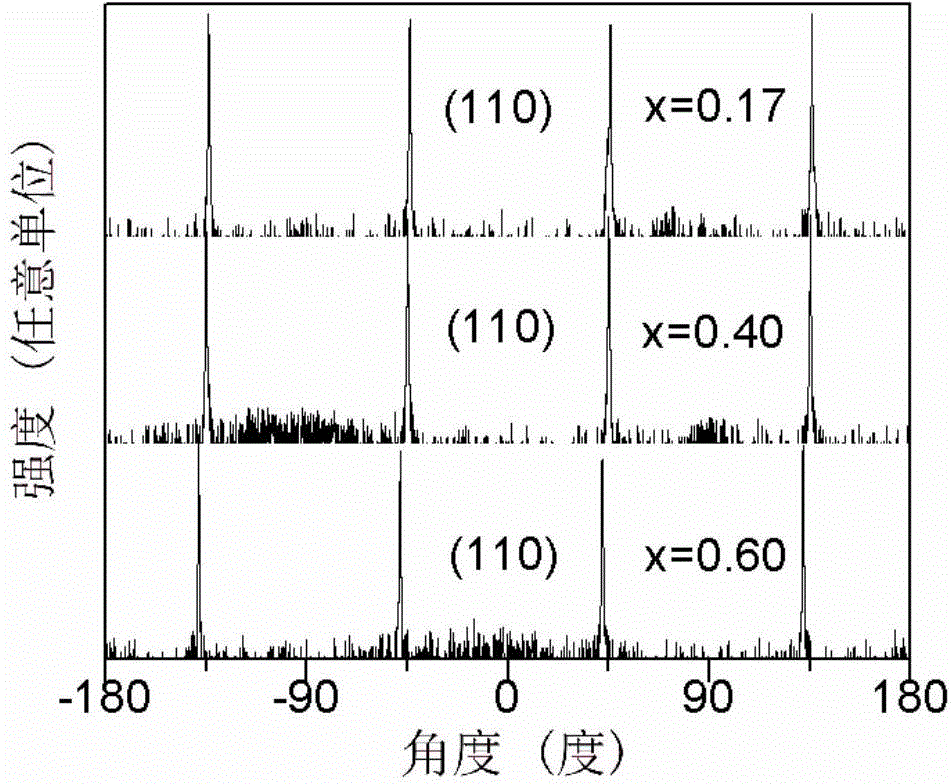

[0035] According to our structural and magnetic analysis of the samples prepared in the present invention, the adjustable three-target RF reactive sputtering epitaxial perovskite La 1-x Sr x CoO 3 The best implementation mode of thin film preparation method is described in detail:

[0036] The adjustable three-target reactive sputtering epitaxial lanthanum strontium cobalt oxide thin film equipment of the present invention adopts the KPS-450 adjustable three-target ultra-high vacuum magnetron sputtering coating equipment produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences. The characteristic steps of its method of operation are as follows:

[0037] 1. Install a piece of La with a purity of 99.99% on one of the targets of the coating machine 0.67 Sr 0.33 CoO 3 Target, and adjust the target surface to the direction parallel to the horizontal plane, the thickness of the target is 4-6mm, and the diameter is 60mm. in la 0.67 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com