Secondary aluminum prepared by using Al-Ti-C-Sr alloy refiner and preparation thereof

A technology of recycled aluminum and refiner, applied in the field of recycled aluminum and its preparation, can solve the problems of high purchase cost and use cost, unfavorable large-scale production and use of factories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0046] Preparation of Al-10Sr Alloy

[0047] This example specifically illustrates the preparation process of the Al-10Sr alloy. First, industrial pure aluminum is melted in a graphite crucible; after the pure aluminum is melted, the temperature is raised to 830°C; then industrial pure strontium is added to the aluminum melt; the heat preservation is 15 minutes; the melt is stirred Afterwards, it is refined with high-purity argon gas (purity 99.9%); it is obtained by pouring into a preheated metal mold after removing slag.

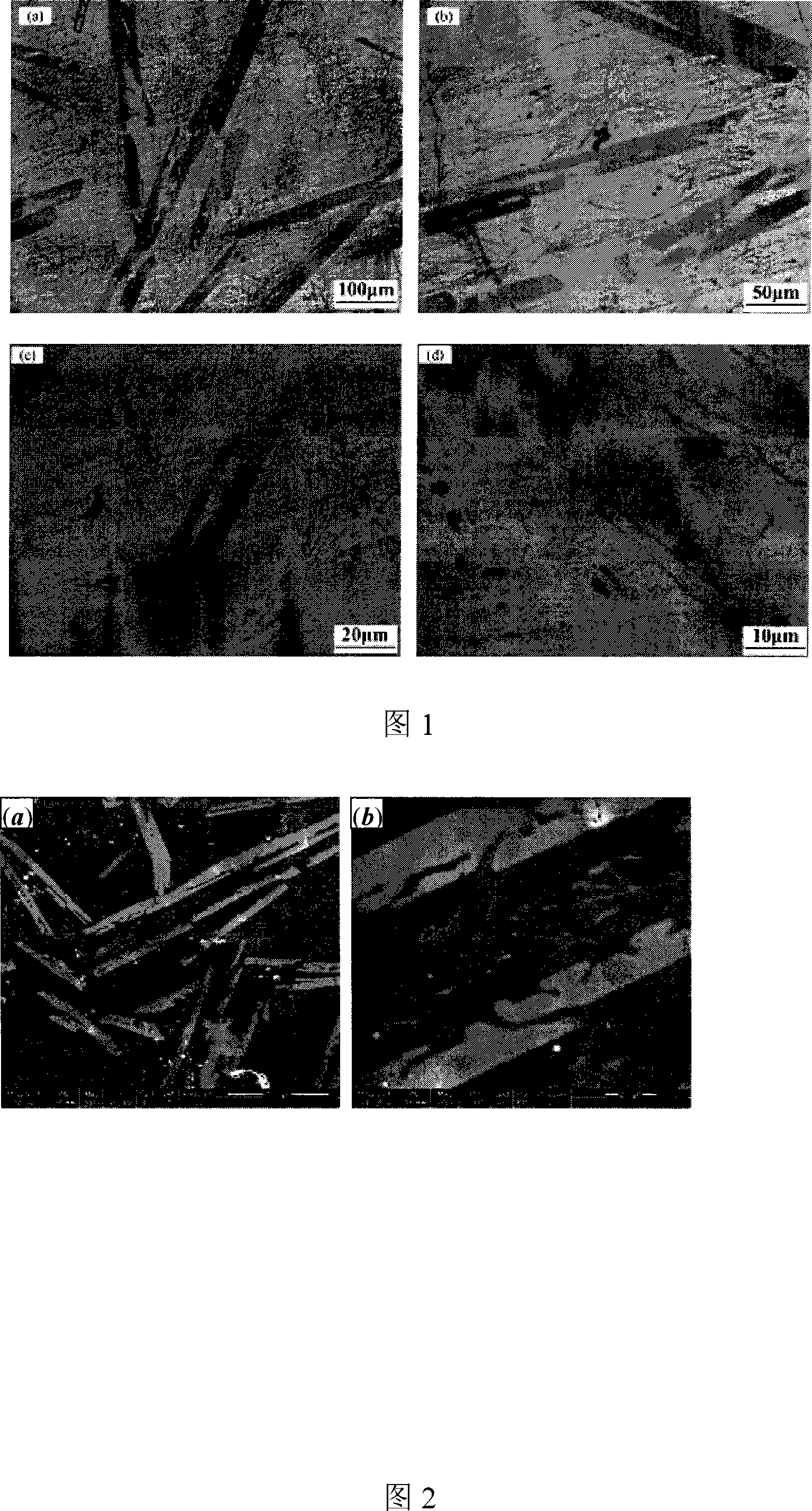

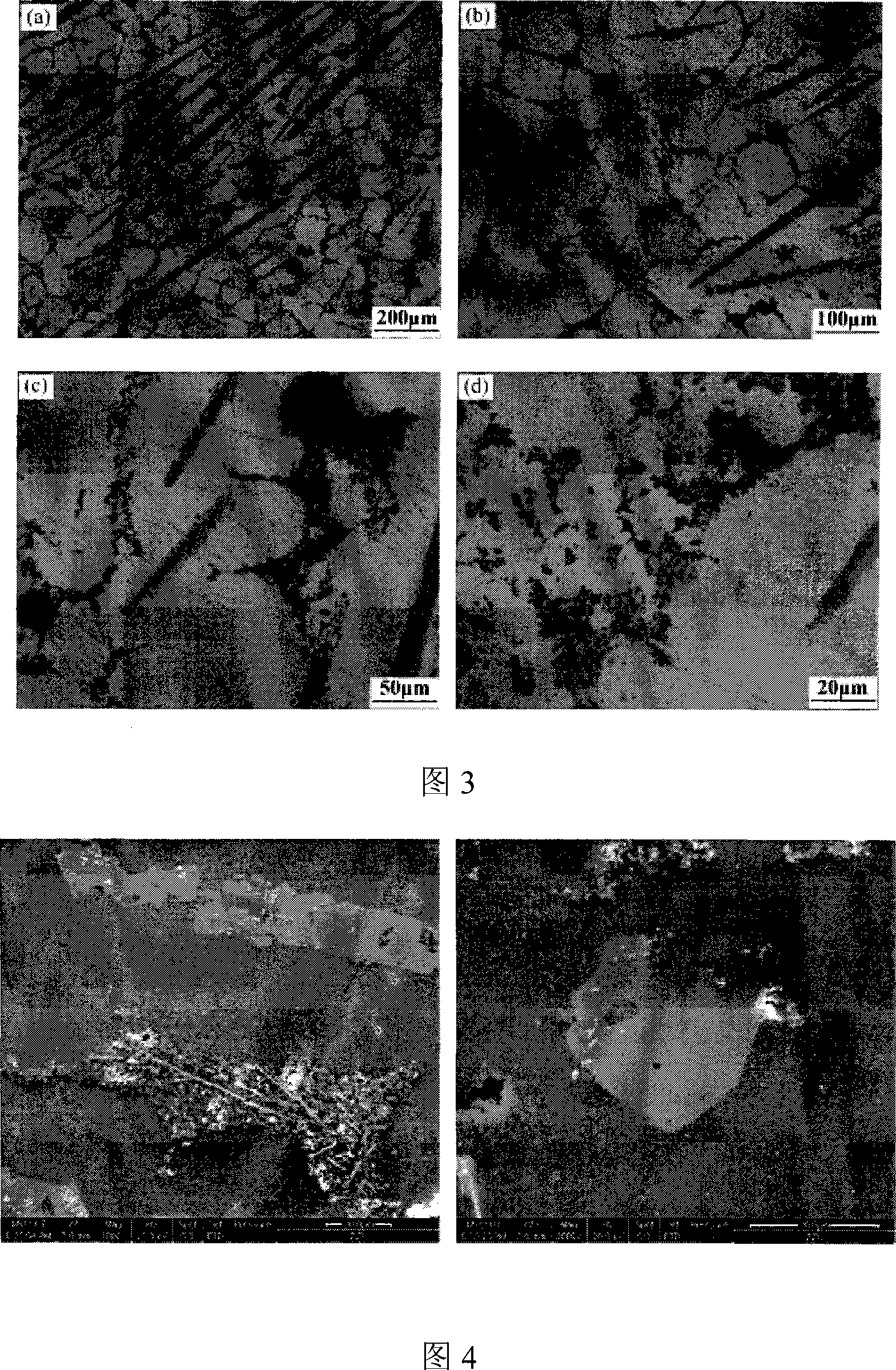

[0048] Then the microstructure of the Al-10Sr alloy was observed. Figure 1 is the OM microstructure of Al-10Sr alloy; Figure 2 is the SEM microstructure of Al-10Sr master alloy. It can be seen from Figures 1 and 2 that the Al-10Sr master alloy structure is composed of matrix, lath structure and fine needle structure. The width of the lath tissue is about 20 μm. Since the addition of Sr makes it easier for the aluminum melt to absorb gas, and the refini...

preparation Embodiment 2

[0050] Preparation of Al-Ti-C-Sr Alloy Refiner

[0051] This example is used to illustrate the Al-Ti-C-Sr alloy refiner. First, preheat the graphite powder in a crucible resistance furnace at 700°C±5°C for 30-60min, K 2 TiF 6 Preheat in a drying oven at 80°C for 30-60 minutes; melt industrial pure aluminum with a medium-frequency induction furnace; overheat the aluminum melt to 800-900°C, add preheated potassium fluotitanate and graphite powder; stir the melt with a graphite stirrer Sprinkle aluminum alloy covering agent with 10% of the melt weight on the surface of the melt and keep it warm for 20 minutes; raise the temperature to above 1200°C and keep it warm for 15 minutes; remove the surface salt layer and slag; cool down to 800-900°C, add preheating The Al-10Sr alloy (Al-10Sr alloy is selected in the generation of TiAl 3 , TiC particles and then add aluminum melt); after heat preservation, stir with graphite stirrer; cast in sand mold, its specific composition is as ...

preparation Embodiment 3

[0056] Refining Treatment of Secondary Alloy Using Al-Ti-C-Sr Alloy Refiner

[0057] raw material

[0058] The raw materials are recycled aluminum material, Al-Ti-C-Sr alloy refiner (Sr weight percentage is greater than 10%) and other materials.

[0059] Preparation equipment and tools

[0060] The heating equipment is a crucible resistance furnace and an oven, and other tools include slag removal tools, bell jars, stirring tools and metal molds.

[0061] secondary alloy smelting

[0062] The smelting process is as follows: use a graphite crucible to melt the regenerated alloy in a crucible resistance furnace at 740°C, heat it for 15 minutes after the regenerated alloy is completely melted, and use an aluminum alloy refining agent to refine and degas. After the refining is completed, the surface slag is removed, and the preheated Al-Ti-C-Sr alloy refiner is added to the recycled alloy melt. The weight ratio of the Al-Ti-C-Sr alloy refiner to the recycled alloy is 2: 1000, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com