Al-Mg-Mn-Zr-Sr alloy and preparation method thereof

A technology of al-mg-mn-zr-sr and alloy, which is applied in the field of high-performance structural materials, can solve application problems and achieve the effects of simple operation process, inhibiting grain growth and improving elongation

Active Publication Date: 2011-04-27

CENT SOUTH UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] As a cheap alkaline earth element, strontium element has simple preparation process and low price in the middle of Al-Sr, but it has not been widely used in aluminum alloys. It is only used as a part of Al-Si casting alloys. In the field of wrought aluminum alloys, it is only found that it has been used as a trace element in the 6069 aluminum alloy registered in the United States in 1994, but it has not yet been used to improve Al-Mg-Mn by alloying technology of strontium. - Literature report on the mechanical properties of high-strength weldable aluminum alloys in the Zr series

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

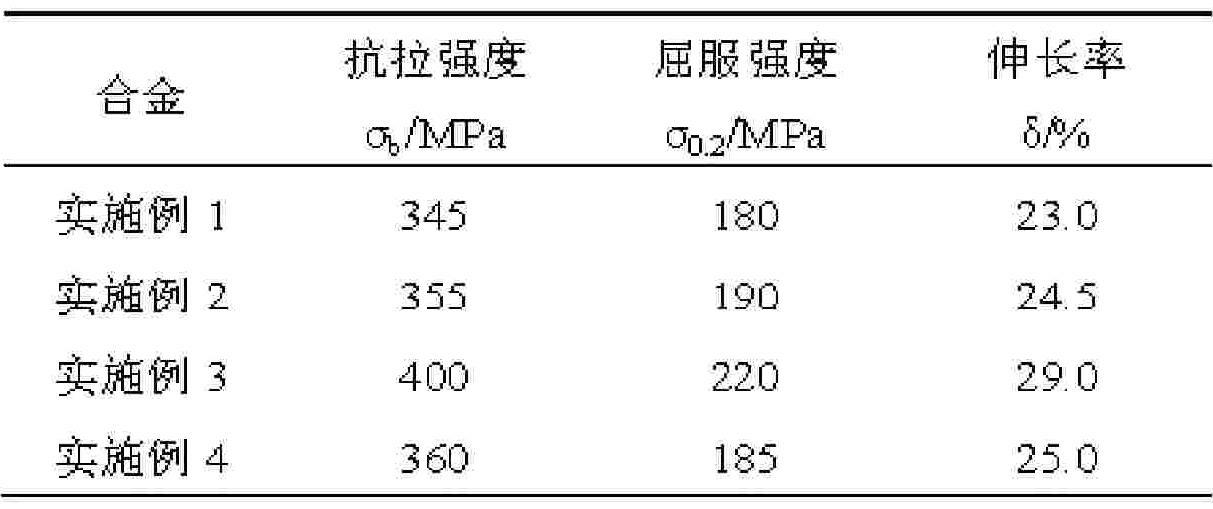

Embodiment 1

[0023] Example 1: The composition is: 6.0% Mg-0.5% Mn-0.1% Zr; does not contain strontium;

Embodiment 2

[0024] Example 2: The composition is: 6.0% Mg-0.5% Mn-0.1% Zr-0.05% Sr;

Embodiment 3

[0025] Embodiment 3: The composition is: 6.0% Mg-0.5% Mn-0.1% Zr-0.1% Sr;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a medium- and high-strength, high-toughness and weldable Al-Mg-Mn-Zr-Sr alloy containing strontium, which consists of the components of Al, MG, Mn, Zr and Sr. A preparation method thereof comprises the following steps: preparing raw materials according to the weight percentage of each component; then heating the components to 820 DEG C to 850 DEG C, totally melting, reducing temperature, standing, refining with C2Cl6, pouring into a preheat mould; after homogenizing cast ingot, heating, and extruding to deform with the extruding ratio of 12. The invention is reasonable in component proportion, easy to process and manufacture, simple in operation process and uses Sr element for alloying, thereby effectively improving the organizational structure of aluminum alloy, the comprehensive mechanical property of aluminum alloy and is adapted for industrialized application. The invention provides an achievable way to improve the comprehensive mechanical property of the medium- and high-strength and weldable aluminum alloy in the Al-Mg-Mn-Zr system.

Description

Technical field [0001] The invention discloses a medium-high-strength and high-toughness weldable Al-Mg-Mn-Zr-Sr alloy and a preparation method thereof, and belongs to the field of high-performance structural materials. Background technique [0002] Al-Mg series alloys are heat-treated non-strengthened aluminum alloys, which can be used after cold working and stabilization annealing. This alloy has medium strength, good corrosion resistance and weldability, and is used in aviation, aerospace, chemical, electronics, automotive and machinery It is widely used in manufacturing. However, with the development of aviation, aerospace, and ship technology, the strength of aluminum-magnesium alloys needs to be further improved. [0003] Since the alloy cannot be strengthened by heat treatment of the metal, a suitable microalloying treatment is adopted to obtain finer grains to play the role of fine-grain strengthening. At the same time, the sub-fine particles formed during the microalloyin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C21/06C22C1/02C22C1/06C22F1/047

Inventor 李慧中梁霄鹏刘楚明

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com