Thermistor material and preparation method and application thereof

A thermistor and resistor technology, applied in the field of resistance materials, can solve the problems of high resistivity and high B value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

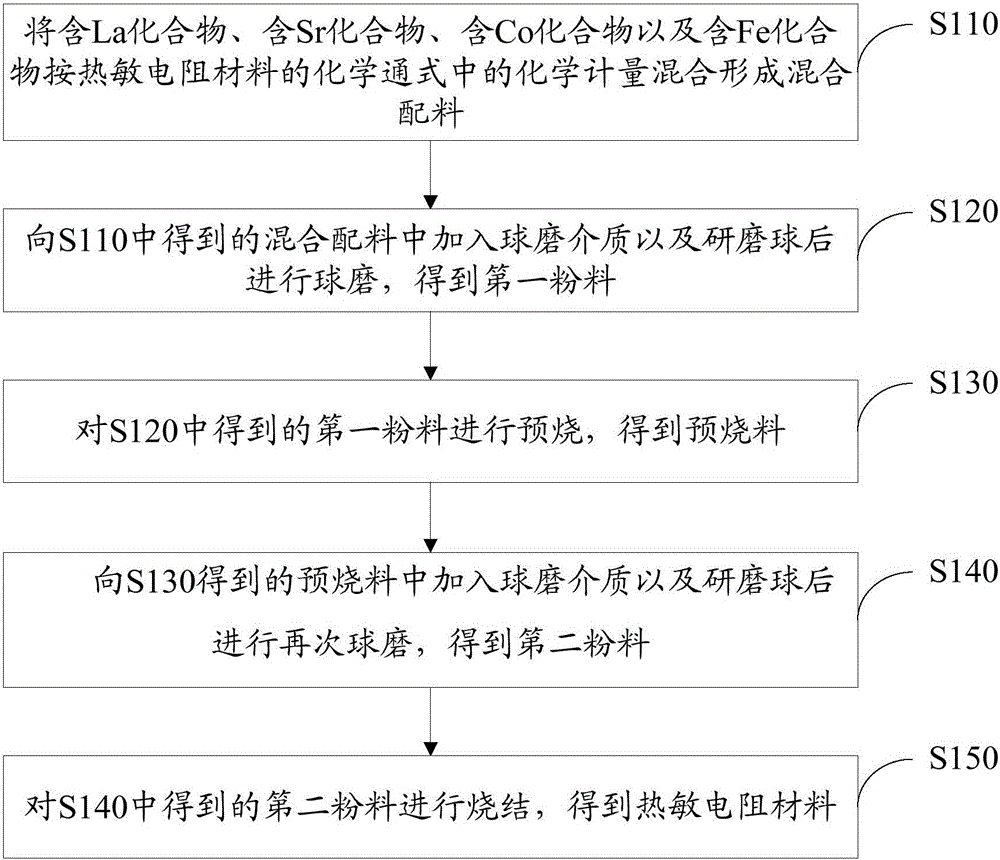

[0036] Such as figure 1 As shown, a method for preparing a thermistor material according to an embodiment includes the following steps S110-S150.

[0037] S110, mixing the La-containing compound, the Sr-containing compound, the Co-containing compound and the Fe-containing compound according to the stoichiometry in the general chemical formula of the thermistor material to form a mixed ingredient.

[0038] Among them, the general chemical formula of the thermistor material is La x Sr 1-x co y Fe 1-y o 3 , 0<x<1, 0<y<1.

[0039] Furthermore, 0.6≤x≤0.9, 0.4≤y≤0.8. The La-containing compound, the Sr-containing compound, the Co-containing compound and the Fe-containing compound are uniformly mixed according to the stoichiometric amount in the general chemical formula.

[0040] Specifically, the La-containing compound is La 2 o 3 (lanthanum trioxide), the Sr-containing compound is Sr 2 CO 3 (strontium carbonate), the Co-containing compound is Co3 o 4 (cobalt tetroxide), ...

Embodiment 1

[0068] Preparation of La 0.8 Sr 0.2 co 0.4 Fe 0.6 o 3 Porcelain body

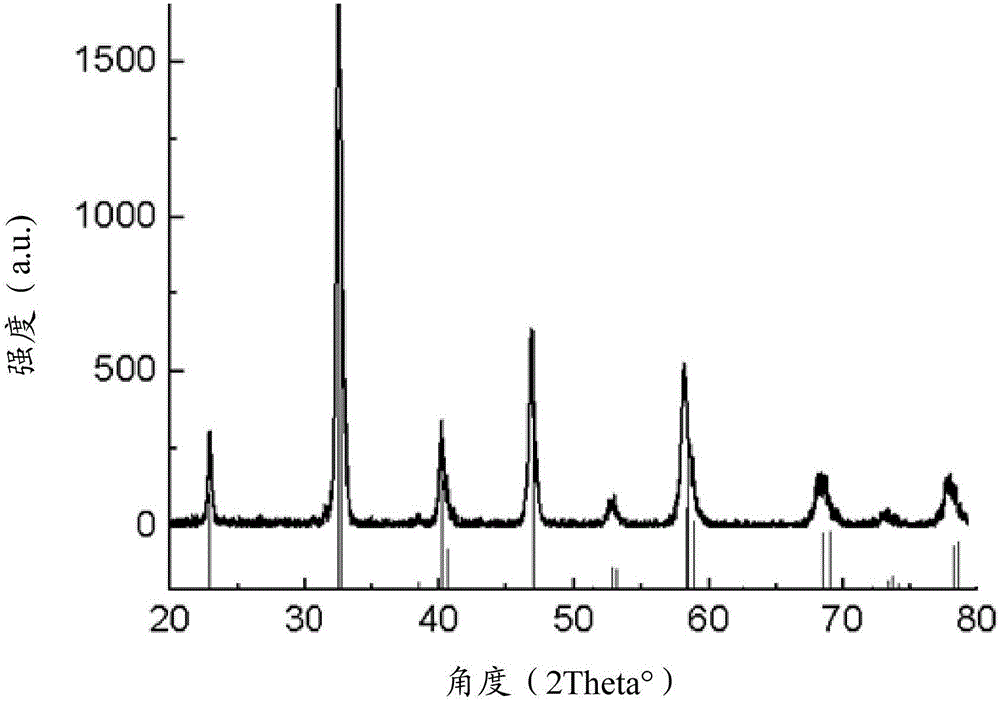

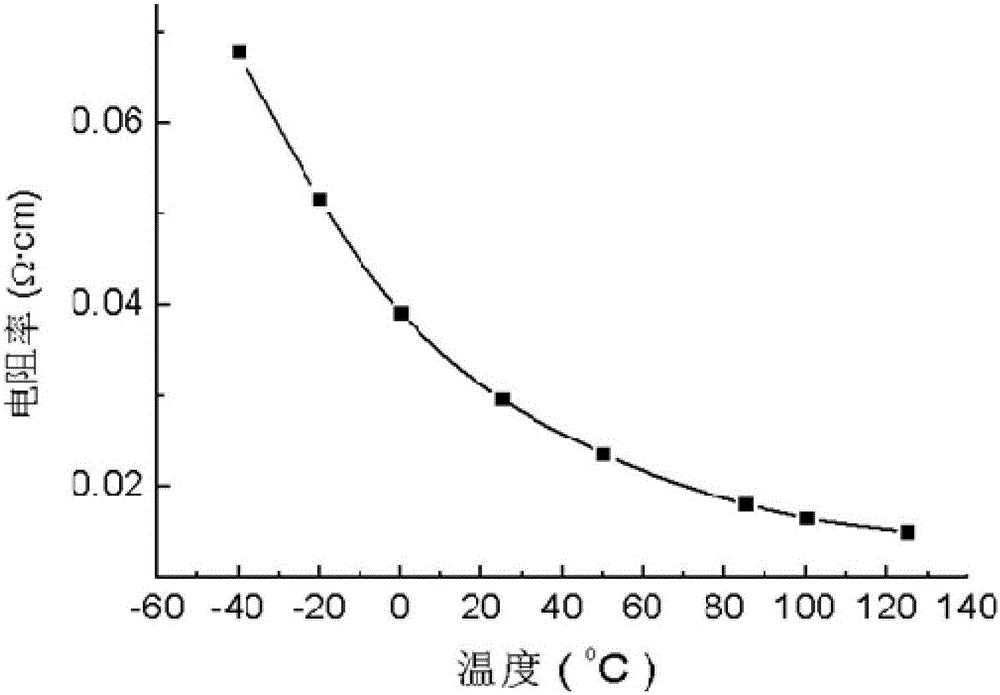

[0069] According to the general chemical formula La 0.8 Sr 0.2 co 0.4 Fe 0.6 o 3 The stoichiometric ratio is weighed to carry out batching by weighing dilanthanum trioxide, strontium carbonate, tricobalt tetroxide and ferric oxide. Put the weighed raw materials into a ball mill jar, add absolute ethanol as the ball milling medium, and zirconia balls as the grinding balls, wherein the quality of the absolute ethanol is 1 times that of the mixed ingredients, and the quality of the zirconia balls is 1 / 2 of the mixed ingredients. 5 times, ball milling and mixing for 6 hours, the speed is 250r / min. The ball-milled slurry was dried with anhydrous ethanol at 85°C and then pre-calcined. The pre-fired temperature was 1100°C, the heating rate was 2°C / min, and the temperature was kept for 12 hours to obtain the pre-fired material. Add absolute ethanol to the calcined material again as a ball milling medium,...

Embodiment 2

[0072] Preparation of La 0.8 Sr 0.2 co 0.7 Fe 0.3 o 3 Porcelain body

[0073] According to the general chemical formula La 0.8 Sr 0.2 co 0.7 Fe 0.3 o 3 The stoichiometric ratio is weighed to carry out batching by weighing dilanthanum trioxide, strontium carbonate, tricobalt tetroxide and ferric oxide. Put the weighed raw materials into a ball mill jar, add absolute ethanol as the ball milling medium, and add zirconia balls as the grinding balls, wherein the mass of absolute ethanol is 1 times that of the mixed ingredients, and the mass of the zirconia balls is the mass of the mixed ingredients 5 times of that, ball milling and mixing for 6 hours at a speed of 250r / min. The ball-milled slurry was dried with anhydrous ethanol at 85°C and then pre-calcined. The pre-fired temperature was 1100°C, the heating rate was 2°C / min, and the temperature was kept for 12 hours. The calcined material is again made of absolute ethanol as the ball milling medium, and zirconia balls a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com