Bismuth-based leadless piezoelectric ceramic and piezoelectric actuator with application of material thereof

A piezoelectric actuator, lead-free piezoelectric technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve problems such as high driving electric field, achieve large output force and anti-fatigue Characteristics, effects of excellent drive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

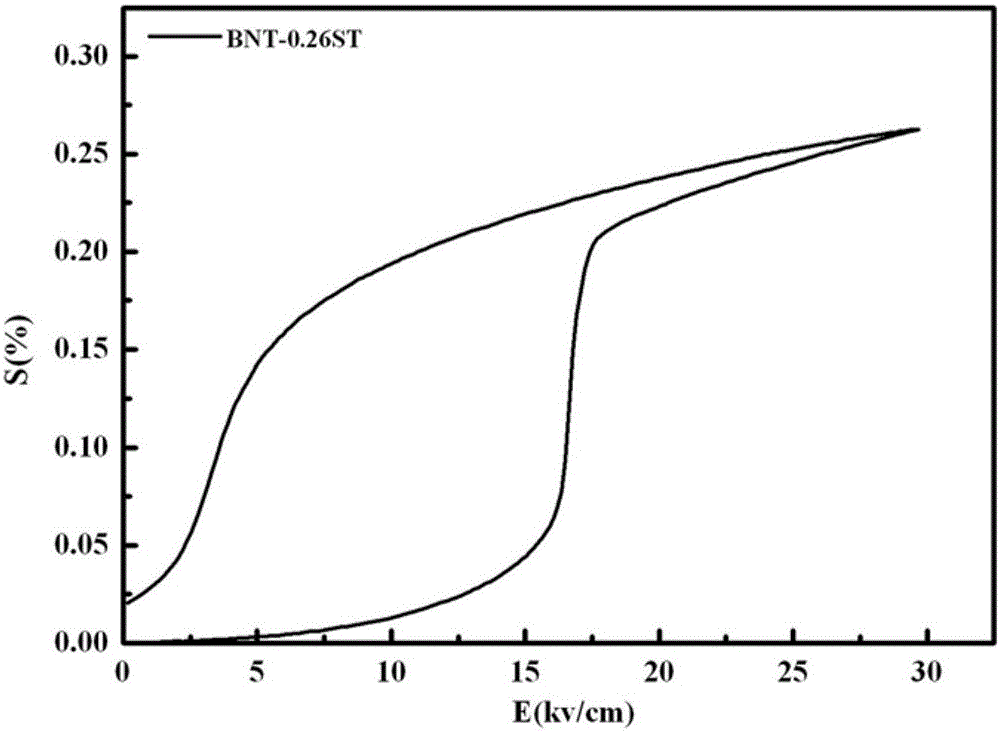

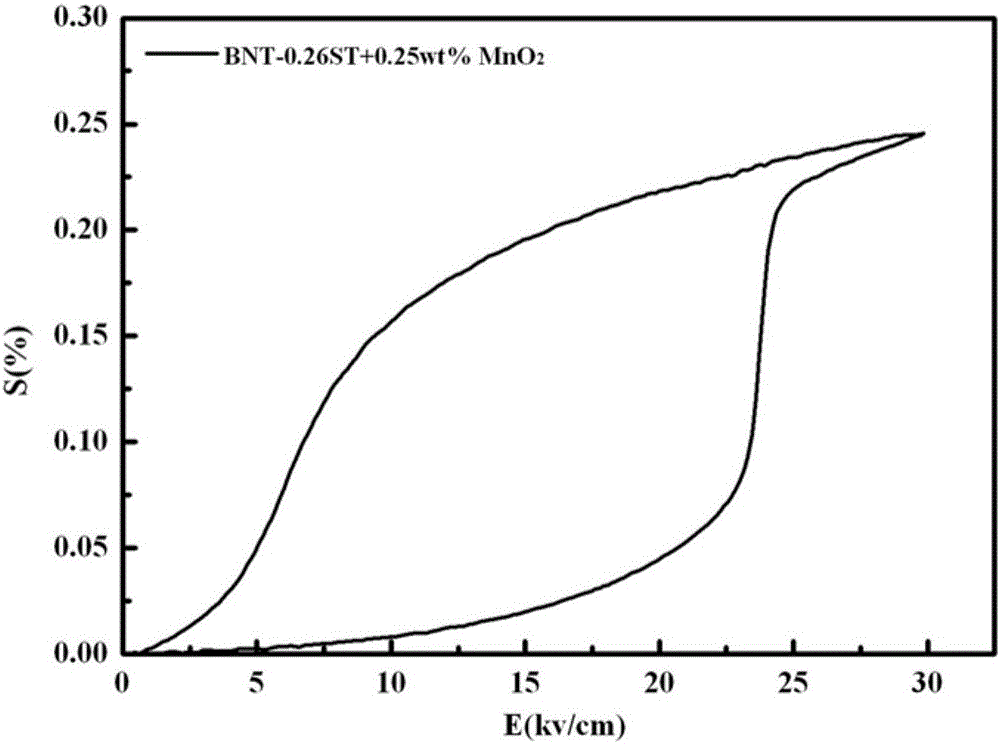

Embodiment 1

[0034] Table 1 gives the formulations of the 2 samples implemented in this example. The present invention uses analytically pure grade Bi 2 o 3 、Na 2 CO 3 、TiO 2 , SrCO 3 , and MnO 2 As the raw material, according to the chemical formula (1-x) Bi 0.5 Na 0.5 TiO 3 +xSrTiO 3 +ywt%MnO 2 , after weighing the raw materials, put them into a ball mill jar, use absolute ethanol as the medium, ball mill for 24 hours, put the obtained slurry into an oven for drying, pass through a 40-mesh sieve, and pre-fire at 820°C for 4 hours. The powder obtained by pre-calcination is crushed, ball milled, dried and passed through a 120-mesh sieve, then added a certain amount of 3wt% PVA aqueous solution to granulate, molded, stayed at 600°C for 2h to remove the glue, and then sintered at 1100-1230°C for 2h . Polish the fired ceramic sheet, burn the silver electrode and let it stand for 24 hours, and finally perform the electrical performance.

[0035] Table 1

[0036] Sample N...

Embodiment 2

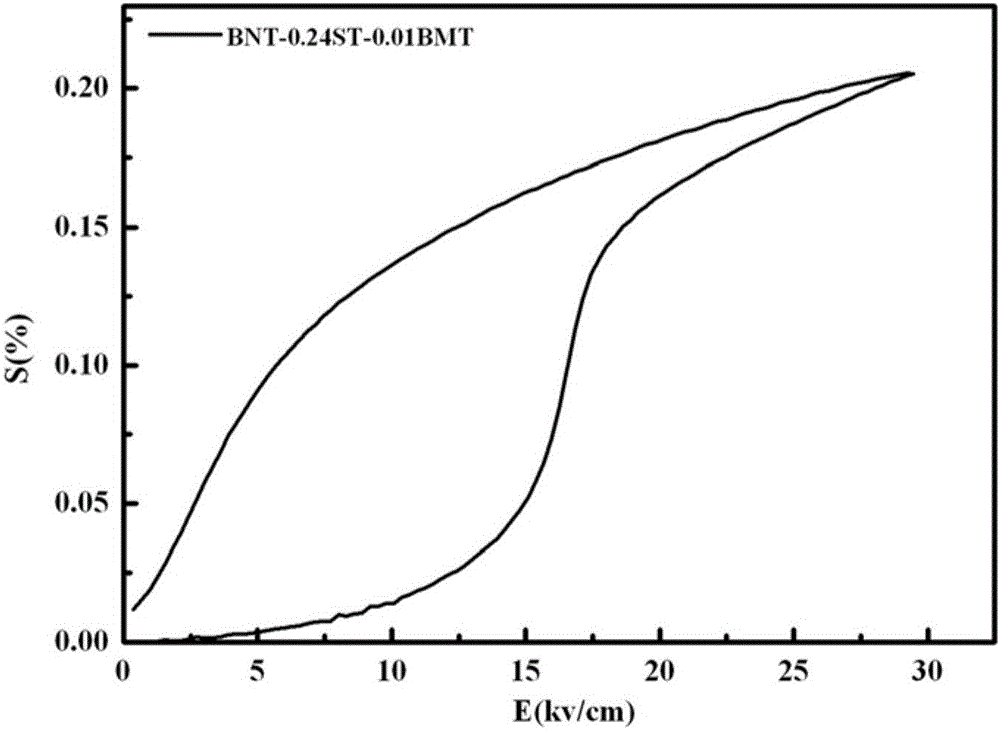

[0038] Table 2 gives the formulations of the 4 samples implemented in this example. The present invention uses analytically pure grade Bi 2 o 3 、Na 2 CO 3 、TiO 2 , SrCO 3 , and MgO as raw materials, according to chemical formula (1-a) [(1-x) Bi 0.5 Na 0.5 TiO 3 +xSrTiO 3 ]+aBi 0.5 (Mg 0.5 Ti 0.5 )O 3 After weighing the raw materials, put them into a ball mill jar, use absolute ethanol as the medium, ball mill for 24 hours, put the obtained slurry into an oven for drying, pass through a 40-mesh sieve, and pre-fire at 860°C for 2 hours. The powder obtained by pre-calcination is crushed, ball milled, dried and passed through a 120-mesh sieve, then added a certain amount of 3wt% PVA aqueous solution to granulate, molded, stayed at 600°C for 2h to remove the glue, and then sintered at 1100-1250°C for 2h . Polish the fired chip, burn the silver electrode, let it stand for 24 hours, and finally conduct the electrical performance test.

[0039] Table 2

[0040]

[004...

Embodiment 3

[0043] Table 3 gives the formulations of the 4 samples implemented in this example. The present invention uses analytically pure grade Bi 2 o 3 、Na 2 CO 3 、TiO 2 , SrCO 3 , and Nb 2 o 5 As a raw material, according to the chemical formula (1-b)[(1-x)Bi 0.5 Na 0.5 TiO 3 +xSrTiO 3 ]+bNaNbO 3 After weighing the raw materials, put them into a ball mill jar, use absolute ethanol as the medium, ball mill for 24 hours, put the obtained slurry into an oven for drying, pass through a 40-mesh sieve, and pre-fire at 900°C for 2 hours. The powder obtained by pre-calcination is crushed, ball milled, dried and passed through a 120-mesh sieve, then added a certain amount of 3wt% PVA aqueous solution to granulate, molded, stayed at 600°C for 2h to remove the glue, and then sintered at 1100-1250°C for 2h . Polish the fired chip, burn the silver electrode, let it stand for 24 hours, and finally conduct the electrical performance test.

[0044] table 3

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com