High-performance semi-solid die cast aluminum alloy and preparation method thereof

A cast aluminum alloy, semi-solid technology, applied in the field of aluminum alloy processing, can solve the problems of product scrap, high heat treatment cost, air bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

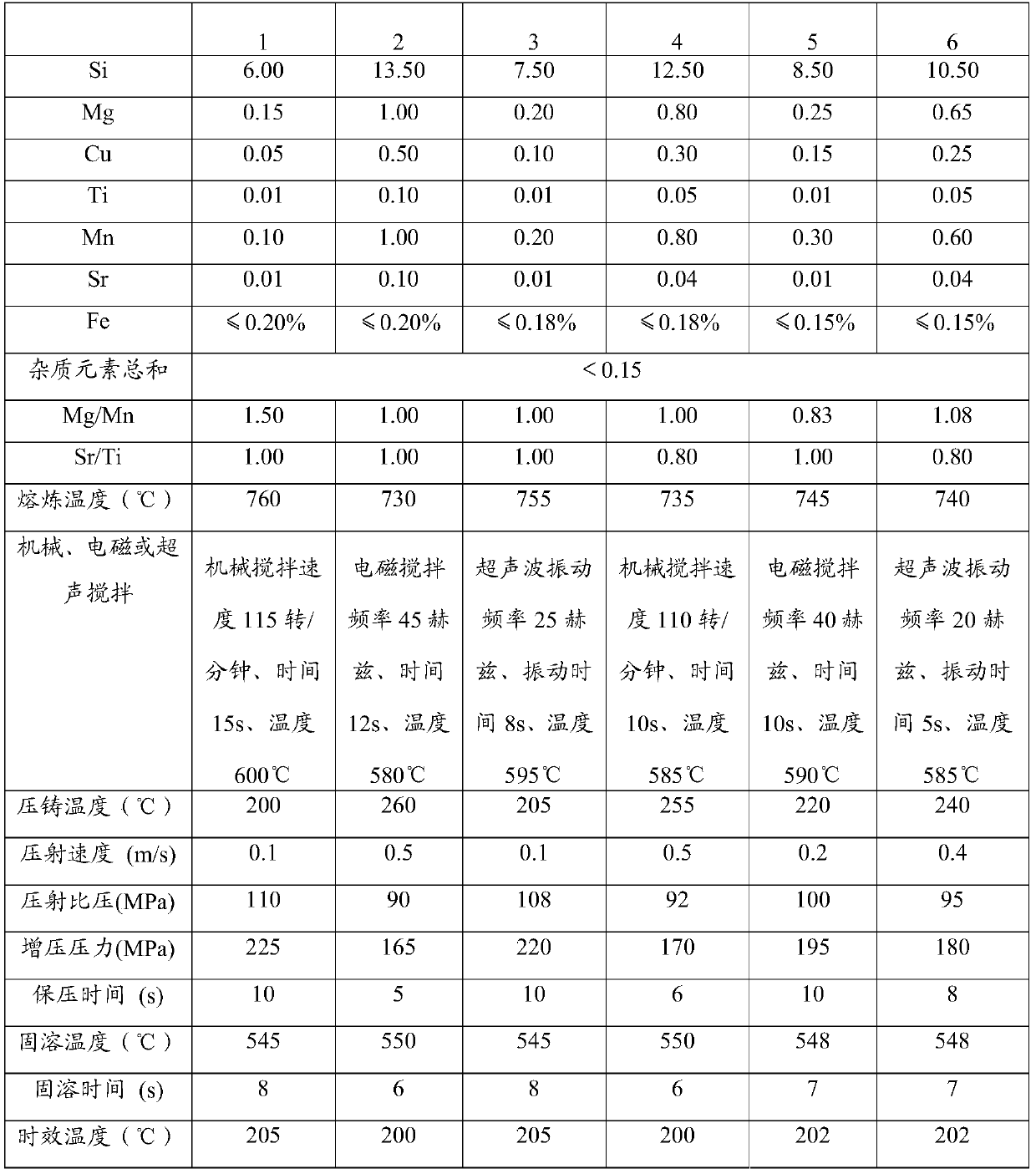

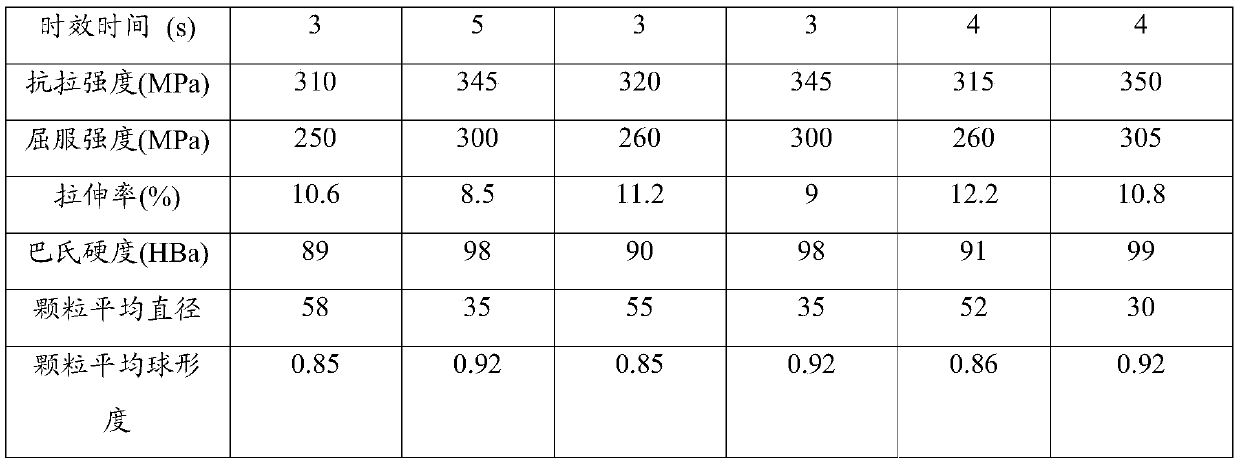

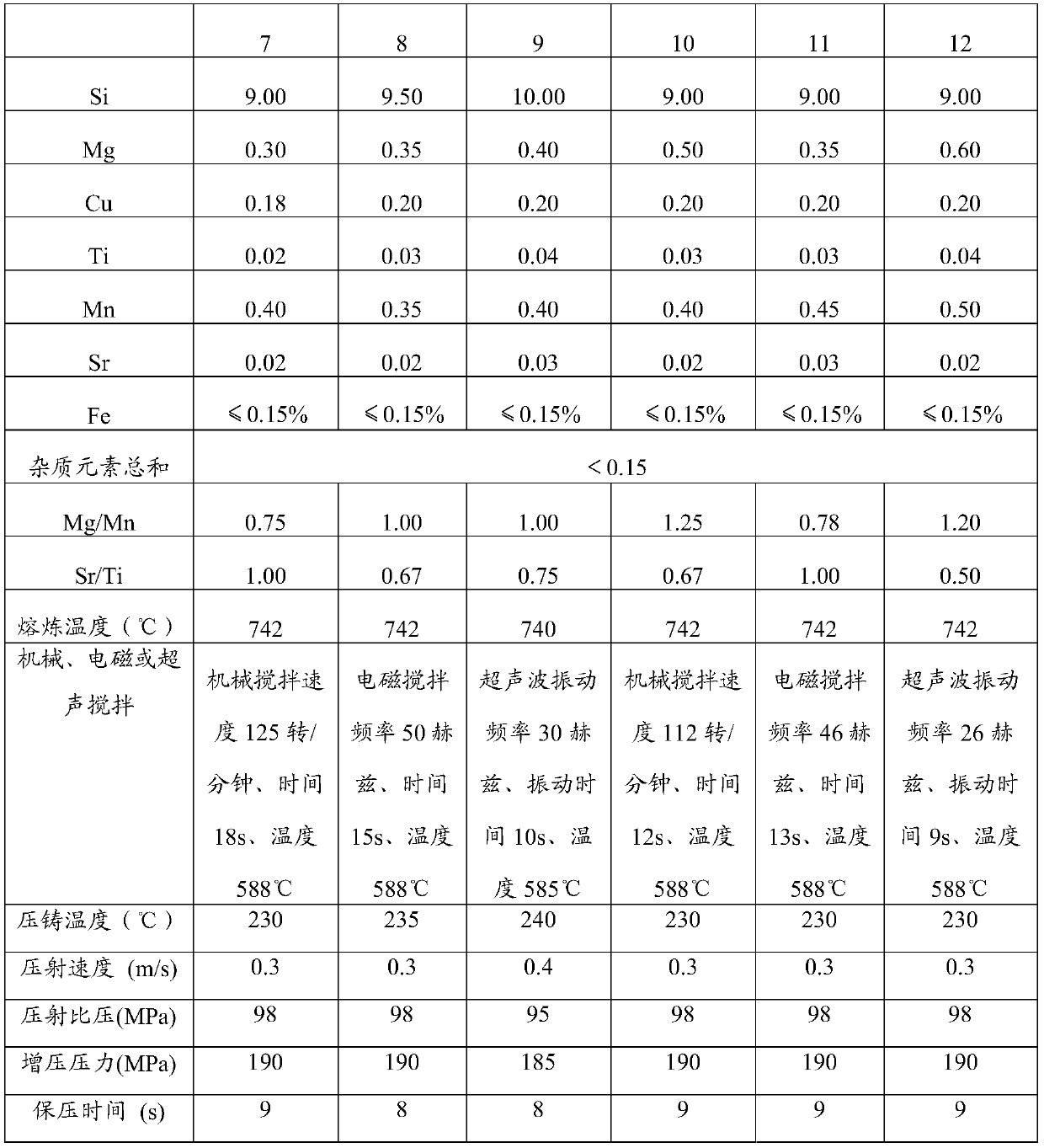

Embodiment 1

[0044] The content of each component of high-performance semi-solid die-casting aluminum alloy is expressed in weight percentage as follows: Si 6.00%, Mg0.15%, Cu 0.05%, Ti 0.01%, Mn 0.10%, Sr 0.01%, Fe≤0.20%, impurity elements The sum is <0.15, and the rest is Al. The preparation method of the high-performance semi-solid die-casting aluminum alloy comprises the following steps:

[0045] 1S batching and smelting: According to the above composition, the raw materials are 99.9% instant silicon, 99.95% magnesium ingot, 99.99% electrolytic copper, 99.8% aluminum ingot, Al-10Ti alloy, Al-10Mn alloy, Al-10Sr alloy, Heating and smelting the prepared raw materials to obtain molten aluminum alloy, wherein the smelting temperature is 760°C;

[0046] 2S semi-solid slurry preparation: prepare the aluminum alloy liquid obtained in step 1S under the conditions of a mechanical stirring speed of 115 rpm and a stirring time of 15 s to prepare an aluminum alloy semi-solid slurry at a temperatu...

Embodiment 2

[0050] The content of each component of the high-performance semi-solid die-casting aluminum alloy is expressed in weight percentage as follows: Si 13.50%, Mg 1.00%, Cu 0.50%, Ti 0.10%, Mn 1.00%, Sr 0.10%, Fe≤0.2%, impurity elements The sum is <0.15, and the rest is Al. The preparation method of the high-performance semi-solid die-casting aluminum alloy comprises the following steps:

[0051] 1S batching and smelting: According to the above composition, the raw materials are 99.9% instant silicon, 99.95% magnesium ingot, 99.99% electrolytic copper, 99.8% aluminum ingot, Al-10Ti alloy, Al-10Mn alloy, Al-10Sr alloy, Heat and smelt the prepared raw materials to obtain aluminum alloy liquid, wherein the smelting temperature is 730°C;

[0052] Preparation of 2S semi-solid slurry: After refining the aluminum alloy liquid obtained in step 1S with hexachloroethane to degas and remove slag, the aluminum alloy liquid was prepared at a temperature of Aluminum alloy semi-solid slurry at...

Embodiment 3

[0056] The content of each component of high-performance semi-solid die-casting aluminum alloy is expressed in weight percentage as follows: Si 7.50%, Mg0.20%, Cu 0.10%, Ti 0.01%, Mn 0.20%, Sr 0.01%, Fe≤0.20%, impurity elements The sum is less than 0.18, and the rest is Al. The preparation method of the high-performance semi-solid die-casting aluminum alloy comprises the following steps:

[0057] 1S batching and smelting: According to the above composition, the raw materials are 99.9% instant silicon, 99.95% magnesium ingot, 99.99% electrolytic copper, 99.8% aluminum ingot, Al-10Ti alloy, Al-10Mn alloy, Al-10Sr alloy, Heating and smelting the prepared raw materials to obtain aluminum alloy liquid, wherein the smelting temperature is 755°C;

[0058] Preparation of 2S semi-solid slurry: After refining the aluminum alloy liquid obtained in step 1S with hexachloroethane to degas and remove slag, prepare the aluminum alloy liquid at a temperature of Aluminum alloy semi-solid slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com