Rare earth double primary colour luminescent material for converting white light by utilizing violet light LED (light-emitting diode) and preparation method thereof

A technology of luminescent materials and dichroic colors, which is applied in the direction of luminescent materials, chemical instruments and methods, and the use of gas discharge lamps. It can solve the problems of color space uniformity and failure to meet indoor lighting, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

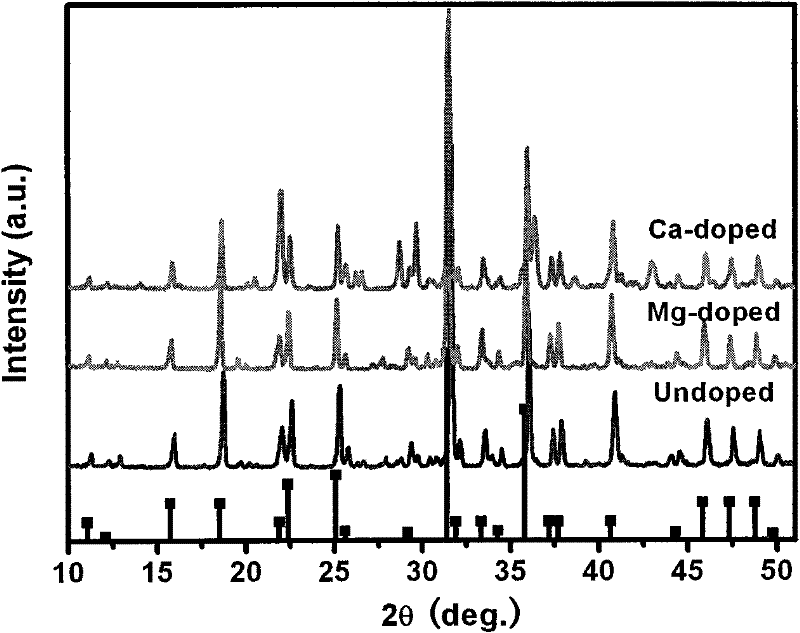

[0030] 1 Preparation of blue phosphor powder

[0031] Materials are selected according to their chemical structure M 0.1 N 3.88 Si 3 O 8 Cl 4 :R 0.02 , when M is the Mg element, N is the Sr element, and R is the Eu element, the following high-purity materials are weighed according to their weight percentages:

[0032] SrCO 3 : 23.58% SrCl 2 .6H 2 O: 55.22%

[0033] SiO 2 : 18.61% Eu 2 o 3 : 0.93%

[0034] MgO: 1.66%

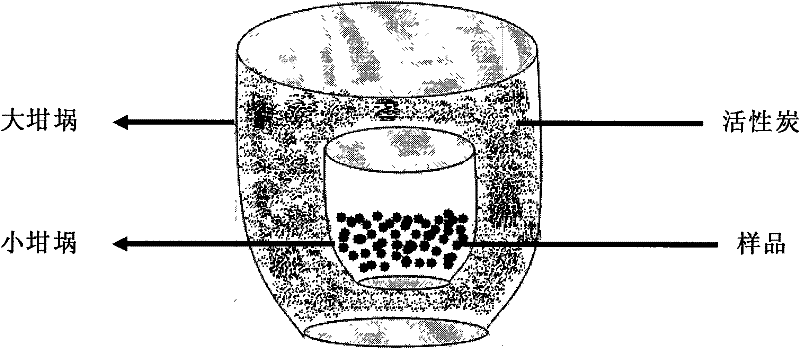

[0035] ① Grind and mix the above weighed materials evenly, put them into a small alumina crucible and cover them, put the small crucible into a large crucible, bury the small crucible with activated carbon and cover it, and then put it in a high temperature furnace at 900°C calcined for 2 hours.

[0036] ② After the sample is cooled, take it out and grind it finely, put it into a small alumina crucible and cover it, put the small crucible into a large crucible, bury the small crucible with activated carbon and cover it, and then put it into ...

example 2

[0045] 1 Preparation of blue phosphor powder

[0046] ①Materials are selected according to their chemical structural formula M 0.15 N 3.82 Si 3 O 8 Cl 4 :R 0.03 , when M is the Mg element, N is the Sr element, and R is the Eu element, the following high-purity materials are weighed according to their weight percentages:

[0047] SrCO 3 : 22.01% SrCl 2 .6H 2 O: 55.21%

[0048] SiO 2 : 19.11% Eu 2 o 3 : 1.92%

[0049] MgO: 1.75%

[0050] ② It is put into a high-temperature furnace and calcined at 950°C for 2.5 hours. It was then put into a high-temperature furnace for calcination at 950° C. for 1.5 hours. The sintering synthesis steps are the same as the example one.

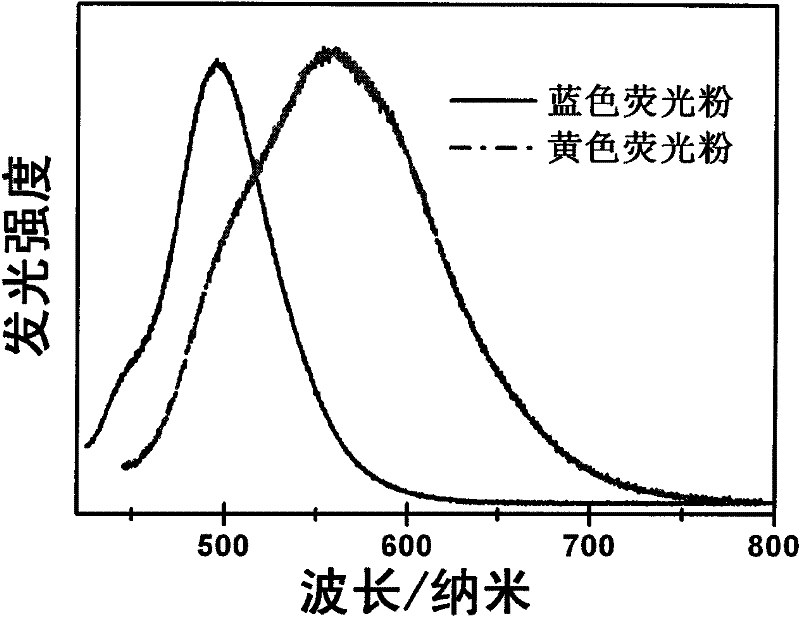

[0051] 2 Preparation of yellow phosphor powder

[0052] ①Materials are selected according to their chemical structural formula W 0.15 S 3.81 Si 3 O 8 Cl 4 :Y 0.04 ·T 0 , when W is the Ca element, S is the Sr element, Y is the Eu element, and T is the Mn element, the following...

example 3

[0058] 1 Preparation of blue phosphor powder

[0059] ①Materials are selected according to their chemical structural formula M 0.35 N 3.71 Si 3 O 8 Cl 4 :R 0.04 , when M is the Mg element, N is the Sr element, and R is the Eu element, the following high-purity materials are weighed according to their weight percentages:

[0060] SrCO 3 : 22.88% SrCl 2 .6H 2 O: 53.75%

[0061] SiO 2 : 18.71% Eu 2 o 3 : 2.91%

[0062] MgO: 1.75%

[0063] ②Put it in a high temperature furnace for calcination at 1000°C for 3 hours, and then put it in a high temperature furnace for calcination at 1000°C for 2 hours. The sintering synthesis steps are the same as the example one.

[0064] 2 Preparation of yellow phosphor powder

[0065] ①Materials are selected according to their chemical structural formula W 0.35 S 3.71 Si 3 O 8 Cl 4 :Y 0.04 ·T 0 , when W is the Ca element, S is the Sr element, Y is the Eu element, and T is the Mn element, the following high-puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com