Composite refinement and modification method for improving mechanical performance of aluminium alloy

An aluminum alloy and mechanical technology, which is applied in the field of compound refinement and modification to improve the mechanical properties of A356.2 aluminum alloy, can solve the problems of expensive and limited rare earths, and achieve the effect of facilitating industrial production, easy operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

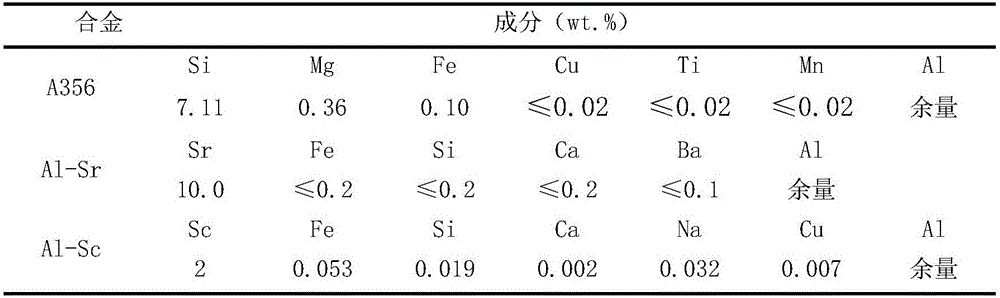

[0028] Preparation of materials: First, saw the A356.2 alloy ingot and cut it into small pieces of about 100g, rinse it with deionized water, then wash it with absolute ethanol and dry it, then put the Al-2Sc and Al-10Sr master alloys into Place the beaker filled with absolute ethanol in an ultrasonic cleaner and then dry it with ultrasonic vibration cleaning and set aside; (the following examples are the same and will not be described again)

[0029] Add 782.14g of A356.2 alloy ingot into a graphite crucible with a preheating temperature of 280°C, and then raise the temperature to 730°C. After the alloy is completely melted in a resistance furnace, skim off the surface scum, and put high-purity argon ( The volume percentage concentration is 99.99%) into the alloy liquid to about 1 / 4 of the bottom of the crucible for refining for 3 minutes; .2 The mass fraction of the alloy is 0.04%, and Sr accounts for 0.02% of the mass fraction of the A356.2 alloy) is wrapped with pure alumi...

Embodiment 2

[0032]774.27gA356.2 alloy ingot is melted in electric resistance furnace, add 24.86gAl-2Sc and 1.64gAl-10Sr intermediate alloy (Sc accounts for the mass fraction of A356.2 alloy is 0.06%, Sr accounts for the mass fraction of A356.2 alloy is 0.02%) as the refinement modificator, other parameters and operation steps are the same as embodiment one.

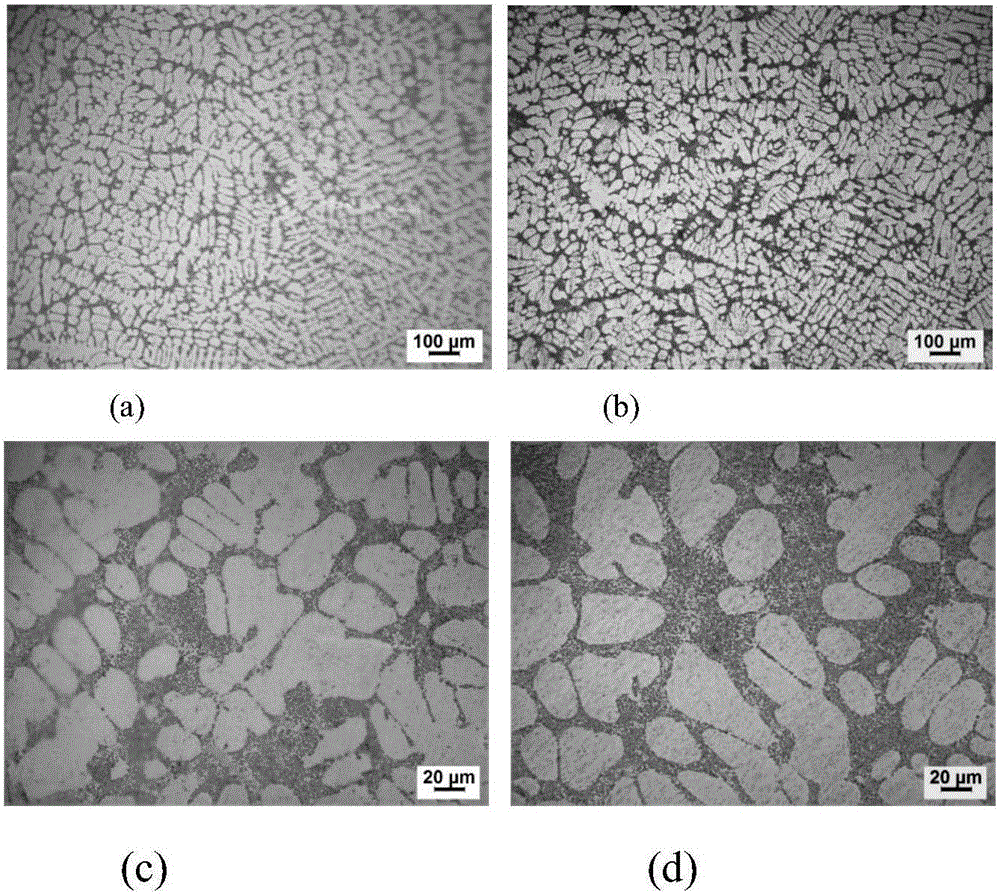

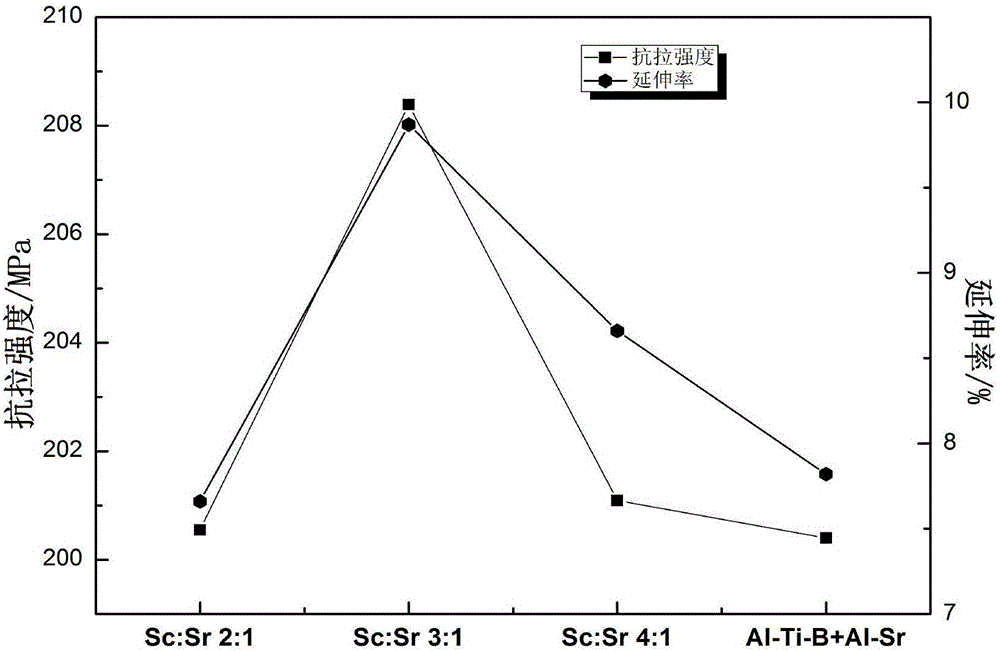

[0033] figure 1 a with figure 1 c are photographs of the metallographic structure of the A356.2 aluminum alloy prepared in this embodiment at 100 times and 500 times in the as-cast state, respectively. pass figure 1 a with figure 1 From the comparison of b, it can be seen that compared with the Al-Ti-B and Al-Sr refinement and modification most commonly used in factories at present, the A356.2 aluminum alloy secondary dendrites refined and modified by Al-Sc and Al-Sr The spacing is 20.09μm, which is 25.86% lower than the secondary dendrite spacing (27.1μm) of the traditional refined and modified A356.2 alloy, that is, its refinin...

Embodiment 3

[0035] 766.24gA356.2 alloy ingot is melted in electric resistance furnace, add 32.86gAl-2Sc and 1.63gAl-10Sr master alloy (Sc accounts for the mass fraction of A356.2 alloy is 0.08%, Sr accounts for the mass fraction of A356.2 alloy is 0.02%) as the refinement modificator, other parameters and operation steps are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com