Compound processing method for simultaneously improving heat-conducting and mechanical properties of die casting aluminum alloy

A technology of casting aluminum alloy and composite treatment, which is applied in the field of composite treatment to simultaneously improve the thermal conductivity and mechanical properties of die-casting aluminum alloy, which can solve the mutual constraints between thermal conductivity and mechanical and casting performance of die-casting aluminum alloy, low element content, and insufficient fluidity and mold release requirements, etc., to achieve the effect of improving thermal conductivity and mechanical properties, good comprehensive effect, and easy to control the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

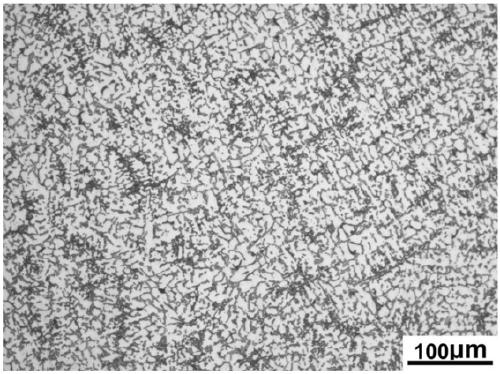

[0053] Embodiment 1: Composite treatment of ADC12 alloy

[0054] The alloy processed in this embodiment is a commercial ADC12 cast aluminum alloy, which is compounded by adding Al-B, Al-Sr and Al-RE master alloys, wherein RE is a mixed rare earth containing Ce and La (the mass ratio of Ce / La is 6 / 4). The composition by weight percentage is: Si: 9.6-12%, Fe<1.3%, Cu: 1.5-3.5%, Mg<0.3%, Mn<0.5%, Zn<1.0%, Ni<0.5%, Sn<0.3%, B: 0.1%, Sr: 0.03%, RE: 0.3%, and the balance is Al.

[0055] The specific steps and process parameters of composite treatment are as follows:

[0056] (1) Melting aluminum alloy. The ADC12 alloy was weighed and then melted to obtain an aluminum alloy melt with a melting temperature of 720°C.

[0057] (2) Melt impurity sedimentation and melt purification. Add Al-B master alloy to ADC12 melt for B treatment, and the addition of B element is controlled at 0.1% of the melt weight. The treatment temperature is 730°C, stirring for 2 minutes until the alloy co...

Embodiment 2

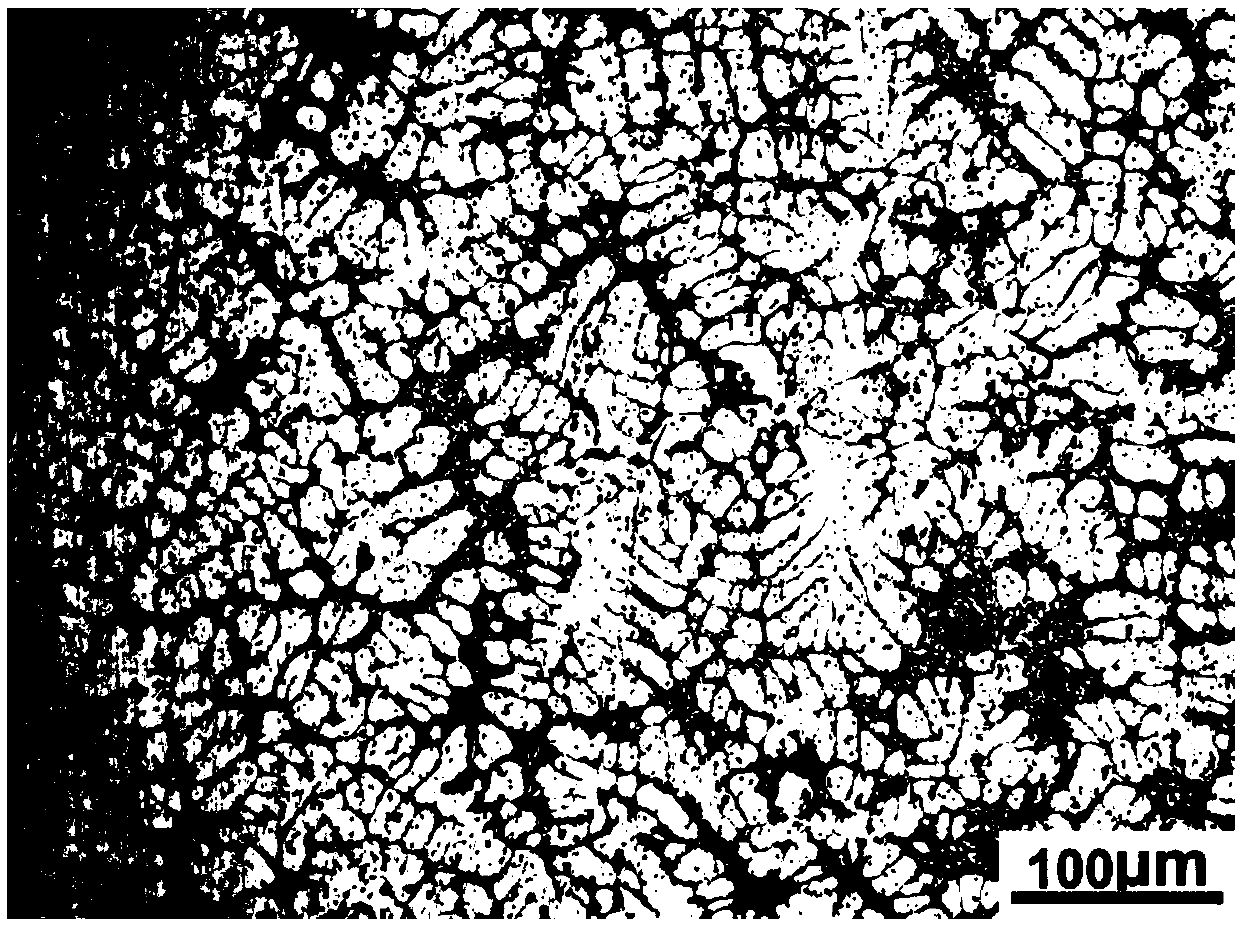

[0064] Embodiment 2: Composite treatment of A356 alloy

[0065] The alloy treated in this example is a commercial A356 alloy, which is compounded by adding Al-B, Al-Sr and Al-RE master alloys, wherein RE is the rare earth La. The composition by weight percentage is: Si: 6.5-7.5%, Fe<0.12%, Cu<0.1%, Mg: 0.3-0.45%, Mn<0.05%, Zn<0.05%, Ti<0.2%, B: 0.05%, Sr: 0.1%, RE: 0.15%, and the balance is Al. The specific smelting process of this embodiment is similar to that of Embodiment 1. The difference is that the addition amount and process parameters are different.

[0066] Concrete steps and process parameters thereof are as follows:

[0067] (1) Melting aluminum alloy. The A356 alloy was weighed and then melted to obtain an aluminum alloy melt with a melting temperature of 750°C.

[0068] (2) Melt impurity sedimentation and melt purification. Add Al-B master alloy to the A356 melt for B treatment, and the addition of B element is controlled at 0.05% of the melt weight. The tr...

Embodiment 3

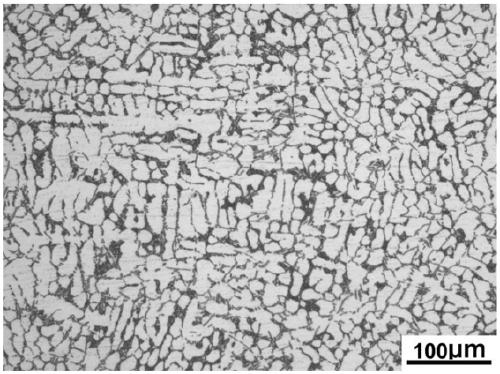

[0074] Embodiment 3: Composite treatment of A380 alloy

[0075] The alloy processed in this embodiment is a commercial A380 alloy, which is compounded by adding Al-B, Al-Sr and Al-RE master alloys, wherein RE is a mixed rare earth containing Ce and La (the mass ratio of Ce / La is 6 / 4 ). The composition by weight percentage is: Si: 7.5-9.5%, Fe<2.0%, Cu: 3.0-4.0%, Mg<0.1%, Mn<0.5%, Zn<3.0%, Ni<0.5%, Sn<0.35%, B: 0.05%, Sr: 0.2%, RE: 0.1%, and the balance is Al.

[0076] The specific smelting process of this embodiment is similar to that of Embodiment 1. The difference is that the addition amount and process parameters are different.

[0077] Concrete steps and process parameters thereof are as follows:

[0078] (1) Melting aluminum alloy. The A380 alloy was weighed and then melted to obtain an aluminum alloy melt with a melting temperature of 720°C.

[0079] (2) Melt impurity sedimentation and melt purification. Add Al-B master alloy to the A356 melt for B treatment, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com