Red luminous silicon-oxygen nitride fluorescent material, preparation method and light emitting device using same

A silicon oxynitride and fluorescent material technology, applied in luminescent materials, chemical instruments and methods, use of gas discharge lamps, etc., can solve the problem of not well meeting the technical requirements of warm white LEDs, low luminous intensity, and large luminous efficiency attenuation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] raw material

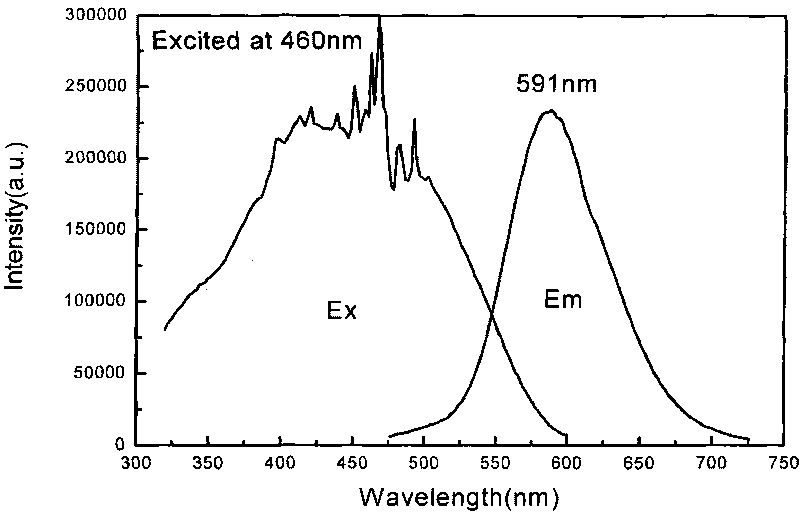

[0079] First, weigh the above-mentioned raw materials with the molar ratio of Ca: Sr: Eu: F: Si = 0.85: 1.25: 0.04: 0.02: 4.85, grind and mix them well, then put them into a boron nitride crucible, put them into a precision Controlled heat treatment furnace, in high-purity N 2 Sintering at 1300-1700°C for several hours in the atmosphere, during this process MI Calcium acetate decomposes to form a certain amount of activated carbon, and the activated carbon further reduces various oxide phases to metal elements. At the same time, each metal element and a small amount of unreduced oxides enter the silicon nitride lattice to obtain Red loose target sintered body. After crushing, grinding and sieving, the silicon oxygen nitrogen fluorescent material Ca with orange-red light emission in the present invention is obtained. 0.85 Sr 1.25 Eu 0.04 Si 4.85 o 0.31 f 0.02 N 7.68 . The material has an emission peak wavelength of 591nm under the excitat...

Embodiment 2-62

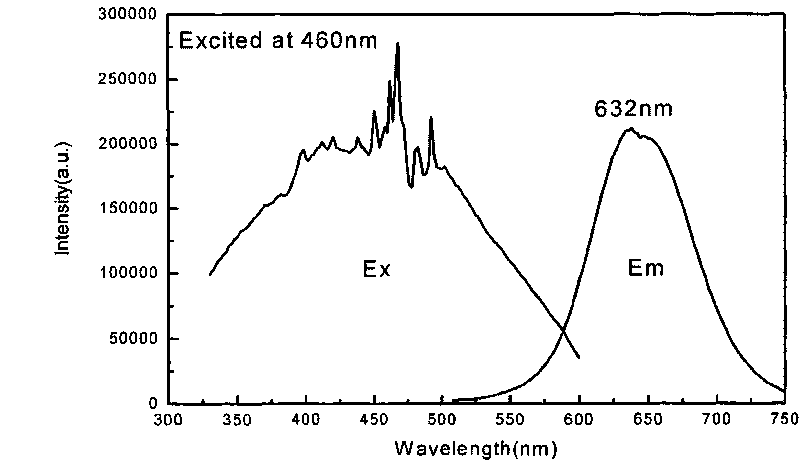

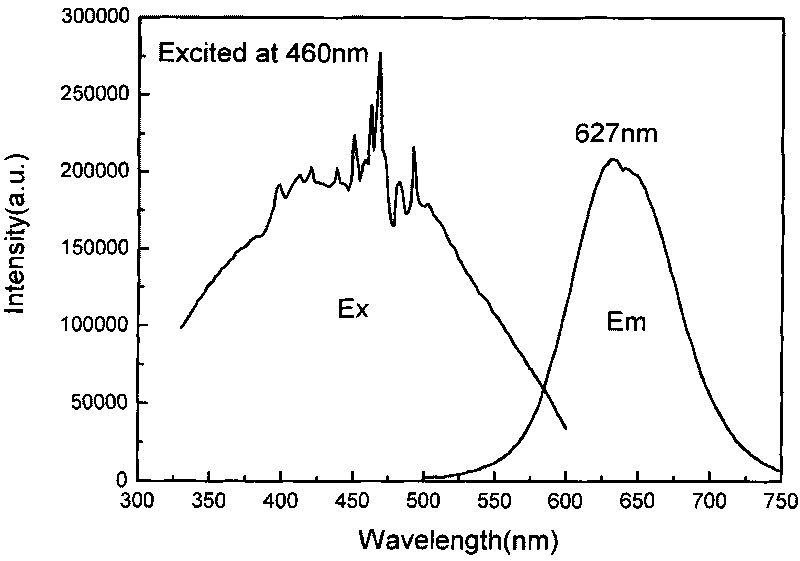

[0080] Embodiment 2-62, preparation method and steps are the same as embodiment 1. Adopt the calcium acetate ((CH) in the embodiment 1 3 COO) 2 Ca·xH 2 O) As a reducing raw material, partial substitution of M by Zn II Alkaline earth metals, Ge partly substituted for Si, F - and / or Cl - The introduction of fluxing and fluorescence enhancing ions, and the introduction of other rare earth co-activating ions can fine-tune the emission peak wavelength and luminous intensity of the fluorescent material. According to the preparation method and steps of preparing the fluorescent material in Example 1, the silicon oxygen nitrogen fluorescent material fluorescent material of Example 2-62 with orange-red emission varying in the range of emission peak wavelength from 580 to 680 nm was prepared.

[0081] Table 1 shows the coefficient value range, component composition and emission peak wavelength corresponding to the expression (1) of the fluorescent materials of each embodiment.

[...

Embodiment 63

[0087] raw material

[0088] First, weigh the above-mentioned raw materials with the molar ratio of Ca:Sr:Eu:F:Si=0.35:1.75:0.04:0.02:5, grind and mix them well, then put them into a boron nitride crucible, put them into a precision Controlled heat treatment furnace, in high-purity N 2 Sintering at 1300-1700°C for several hours in the atmosphere, during this process M I Calcium propionate decomposes to form a large amount of activated carbon, and the activated carbon further reduces various oxide phases to metal elements. At the same time, each metal element and a very small amount of unreduced oxides enter the silicon nitride lattice to Obtain a red loose target sintered body. After crushing, grinding and sieving, the silicon oxygen nitrogen fluorescent material Ca with orange-red light emission in the present invention is obtained. 0.35 Sr 1.75 Eu 0.04 Si 5 o 0.11 f 0.02 N 8.01 . The emission peak wavelength of the material is at 621nm under the excitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com