A borophosphate scintillation glass for thermal neutron detection and its preparation method

A scintillation glass and thermal neutron technology, applied in rare earth ion-doped borophosphate scintillation glass and preparation thereof, borophosphate scintillation glass for thermal neutron detection and preparation thereof, can solve the problem of high preparation temperature and neutron capture problems such as low element content, to achieve the effect of simple preparation process, short preparation cycle and easy adjustment of chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The method for preparing rare earth ion-doped borophosphate scintillation glass for thermal neutron detection specifically includes the following steps:

[0034] 1) Accurately weigh each raw material according to the composition of the scintillation glass, and mix all the raw materials evenly. The Li 2 The O raw material is mainly composed of lithium carbonate (Li 2 CO 3 ) introduced, B 2 o 3 The raw material is boron oxide (B 2 o 3 ) or boric acid (H 3 BO 3 ) introduction; P 2 o 5 The raw material is ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) is introduced, and the doped Ce 3+ Ions can be introduced in the form of corresponding oxides, halides, carbonates, nitrates or sulfates; the purity of all raw materials should be analytically pure or above;

[0035] 2) Then pour it into an alumina crucible or platinum crucible and melt it into a glass melt. The melting temperature is 700-950°C. After melting, keep it warm for 0.5-3 hours. The working atmosphere ...

Embodiment 1

[0054] 1. Preparation

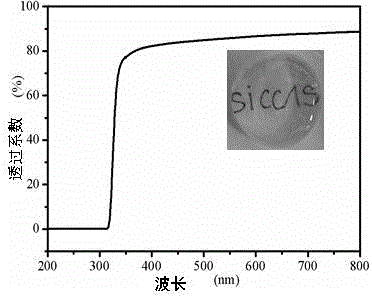

[0055] According to the specific glass composition of Example 1 in Table 1, the glass raw materials were accurately weighed, and after the glass raw materials were fully ground in an agate mortar for 15 minutes, they were directly placed in a high-temperature electric furnace at 865° C. for 30 minutes to obtain a uniform glass melt. Subsequently, the above melt was poured into a stainless steel mold with a preheating temperature of 300°C for casting, and the formed glass was quickly placed in a muffle furnace at 300°C for 5 hours for annealing treatment. The obtained scintillating glass primary product is processed into 10×10×2mm after cutting, surface grinding and polishing 3 The scintillation glass of the present invention. Such as figure 1 As shown, the invented scintillation glass has a high optical transmittance of more than 80% in the wavelength range of 320-800nm;

[0056] 2. Test

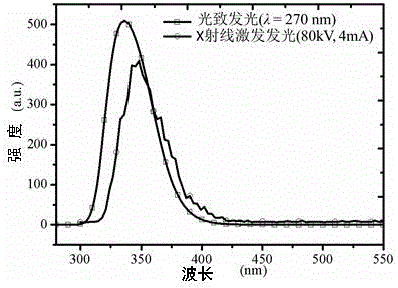

[0057] Using a fluorescence spectrometer (Hitachi F-4600, Ex...

Embodiment 2

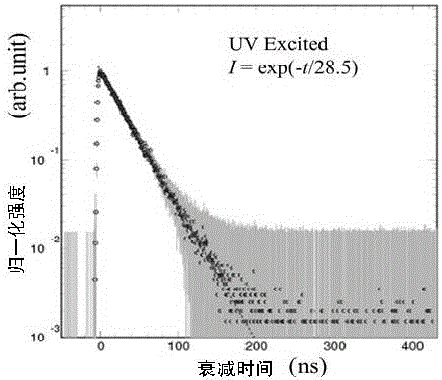

[0063] According to the specific glass composition of Example 2 in Table 1, the glass raw materials were accurately weighed, and after fully grinding the glass raw materials in an agate mortar for 15 minutes, they were directly placed in a high-temperature electric furnace at 865° C. for 30 minutes to obtain a uniform glass melt. Subsequently, the above melt was poured into a stainless steel mold with a preheating temperature of 300°C for casting, and the formed glass was quickly placed in a muffle furnace at 300°C for 5 hours for annealing treatment. The obtained scintillating glass primary product is processed into 10×10×2mm after cutting, surface grinding and polishing 3 The scintillation glass of the present invention. Such as image 3 As shown, it has a fast decay time of 28.5 ns when UV light excites the scintillation glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com