Method for preparing vertical cavity surface emitting laser by in-situ growth perovskite single crystal thin film, and vertical cavity surface emitting laser

A vertical cavity surface emission, single crystal thin film technology, applied in the field of lasers, can solve the problems of high relative threshold of lasers and affecting laser performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

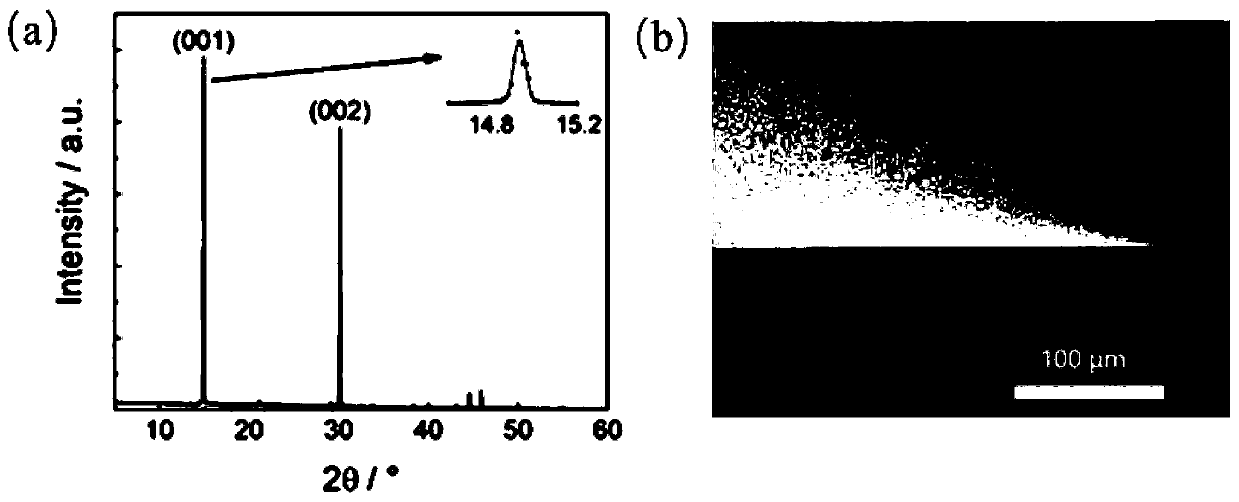

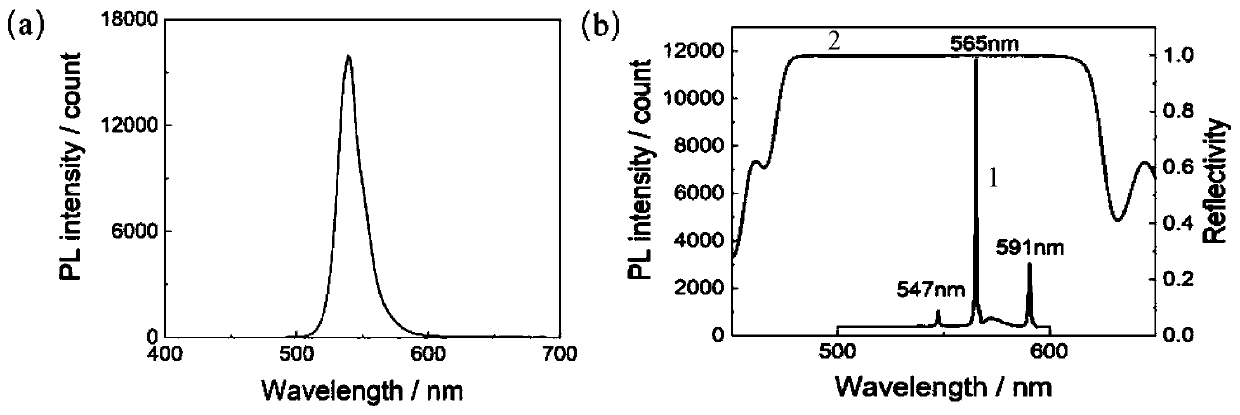

[0044] Prepare a yellow-green perovskite vertical cavity surface-emitting laser with an emission wavelength of about 560nm, and choose a CH with a free-space emission wavelength slightly lower than 560nm 3 NH 3 PbBr 3 (540nm) as a gain medium.

[0045] Experimental steps:

[0046] (1) According to the emission wavelength and CH of the required laser 3 NH 3 PbBr 3 The wavelength of light emission, select a distributed Bragg reflector (DBR) sheet with a central wavelength of about 540nm in the high reflectivity area and a width of 500-600nm, with an area of 1cm 2 ;

[0047] (2) Configure CH 3 NH 3 PbBr 3 Solution:

[0048] Take anhydrous N,N-dimethylformamide (DMF) as solvent, CH 3 NH 3 Br (purity 99%) powder and PbBr 2 (purity 99.99%) powder 1:1 molar ratio mixture as solute, configure CH 3 NH 3 PbBr 3 After the saturated solution was fully stirred and dissolved, the above solution was filtered through a polytetrafluoroethylene filter membrane with a pore size...

Embodiment 2

[0056] Prepare a blue-light perovskite vertical cavity surface-emitting laser with an emission wavelength of about 425nm, and select a CH with a free-space emission wavelength slightly lower than 425nm 3 NH 3 PbCl 3 (410nm) as a gain medium.

[0057] Experimental steps:

[0058] (1) According to the emission wavelength and CH of the required laser 3 NH 3 PbCl 3 The wavelength of light emission, select a distributed Bragg reflector (DBR) sheet with a central wavelength of about 415nm in the high reflectivity area and a width of 400-440nm, with an area of 1cm 2 ;

[0059] (2) Configure CH 3 NH 3 PbCl 3 solution.

[0060] Take a mixture of anhydrous N,N-dimethylformamide (DMF) and anhydrous dimethyl sulfoxide (DMSO) at a volume ratio of 1:1 as a solvent, CH 3 NH 3 Cl (purity 99%) powder and PbCl 2 (purity 99.99%) powder 1:1 molar ratio mixture as solute, configuration CH 3 NH 3 PbCl 3 After the saturated solution was fully stirred and dissolved, the above soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com