Zn-Al-Sr alloy and preparation method thereof

A zn-al-sr alloy technology, applied in metal material coating process, coating, hot-dip plating process, etc., can solve problems such as difficulties in the production process of metal strontium, improve microstructure and mechanical properties, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

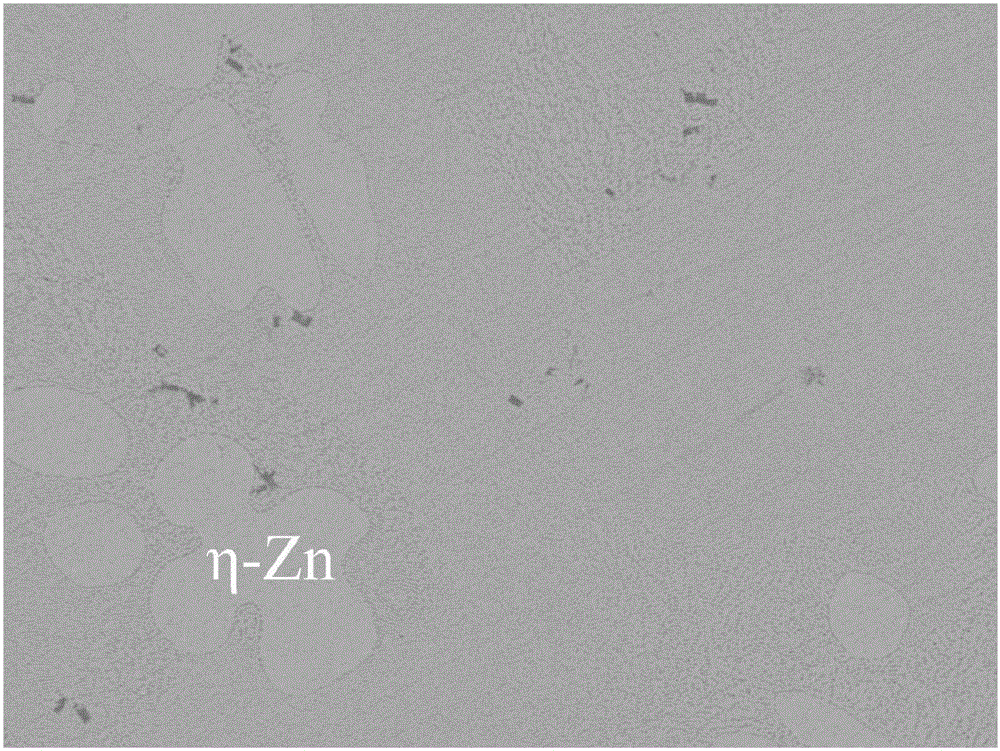

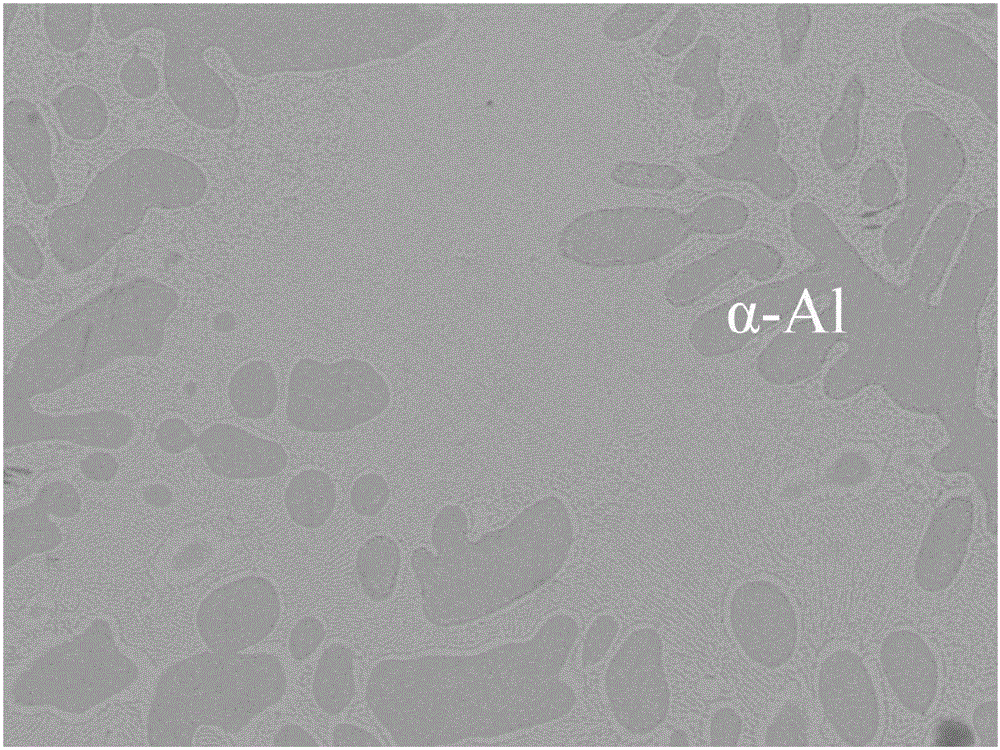

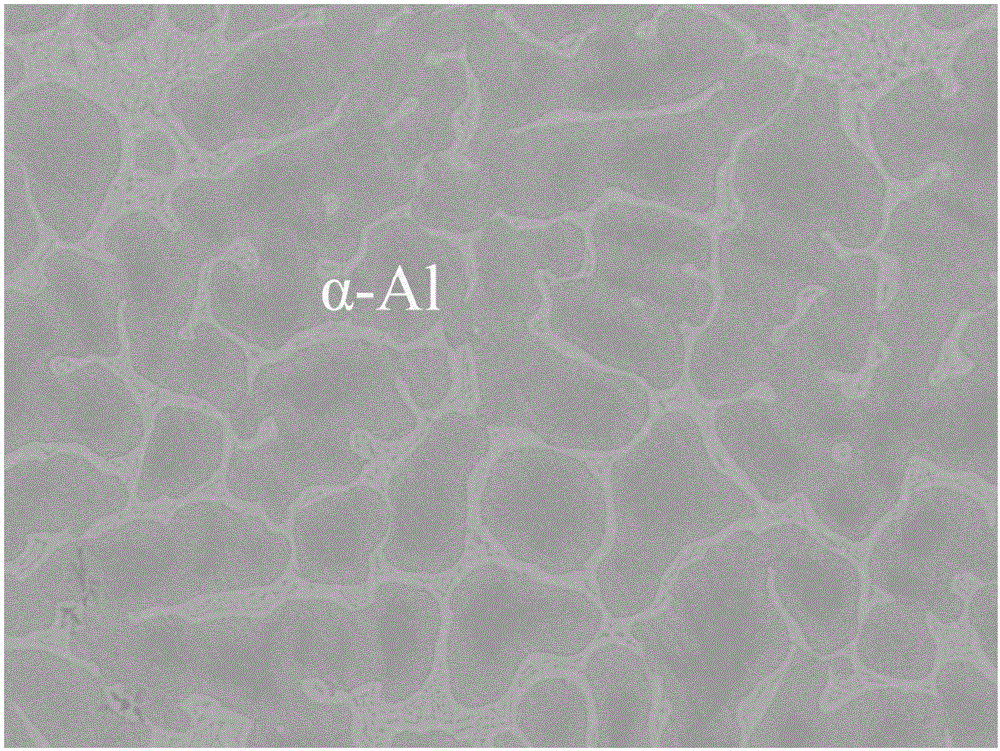

Image

Examples

Embodiment 1

[0026] (1) Analytical pure SrCl 2 ·6H 2 The O salt is placed in a beaker, dried and dehydrated in a drying oven, and ground into powder.

[0027] (2) Weigh the Zn block and SrCl in proportion 2 Powder, of which 114g of Zn block, 6g of Al block, SrCl 2 Powder 6g, after many experiments, it was found that after stirring the Zn-Al liquid, SrCl 2 will float on the surface of Zn liquid, at this time, SrCl 2 The absorption is limited, so SrCl 2 Excessive levels can still be reached.

[0028] (3) Preheat the graphite crucible to dark red, and weigh the SrCl in proportion 2 The powder is placed at the bottom of the crucible and added in SrCl 2 A Zn block and an Al block are placed on the powder, and then the temperature is raised to 700°C-730°C.

[0029] (4) After the Zn block and the Al block are completely melted, stir the Zn-Al liquid and sprinkle SrCl evenly on the surface of the Zn-Al liquid 2 powder to cover.

[0030] (5) The Zn-Al liquid was heated for 1 hour and then...

Embodiment 2

[0035](1) Analytical pure SrCl 2 ·6H 2 O salt was put into a beaker, dried and dehydrated in a drying oven, and ground into powder.

[0036] (2) Weigh the Zn block and SrCl in proportion 2 Powder, of which Zn block 108g, Al block 12g, SrCl 2 Powder 6g, found through many experiments, after stirring the Zn-Al liquid, SrCl 2 Will float on the surface of Zn liquid, at this time for SrCl 2 The absorption is limited, so SrCl 2 Overdose can still be achieved.

[0037] (3) Preheat the graphite crucible to dark red, add the proportionally weighed SrCl 2 The powder was placed at the bottom of the crucible, and in SrCl 2 Put Zn blocks and Al blocks on the powder, and then raise the temperature to 700°C-730°C.

[0038] (4) After the Zn block and Al block are completely melted, stir the Zn-Al liquid and evenly sprinkle SrCl on the surface of the Zn-Al liquid 2 Powder for coverage.

[0039] (5) After heating the Zn-Al liquid for 1 hour, stir again.

[0040] (6) There will be whi...

Embodiment 3

[0044] (1) Analytical pure SrCl 2 ·6H 2 O salt was put into a beaker, dried and dehydrated in a drying oven, and ground into powder.

[0045] (2) Weigh the Zn block and SrCl in proportion 2 Powder, of which Zn block 96g, Al block 24g, SrCl 2 Powder 6g, found through many experiments, after stirring the Zn-Al liquid, SrCl 2 Will float on the surface of Zn liquid, at this time for SrCl 2 The absorption is limited, so SrCl 2 Overdose can still be achieved.

[0046] (3) Preheat the graphite crucible to dark red, add the proportionally weighed SrCl 2 The powder was placed at the bottom of the crucible, and in SrCl 2 Put Zn blocks and Al blocks on the powder, and then raise the temperature to 700°C-730°C.

[0047] (4) After the Zn block and Al block are completely melted, stir the Zn-Al liquid and evenly sprinkle SrCl on the surface of the Zn-Al liquid 2 Powder for coverage.

[0048] (5) After heating the Zn-Al liquid for 1 hour, stir again.

[0049] (6) There will be whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com