Self-reduction multi-loop centralized predictive control system for reheat steam temperature of secondary reheat unit

A technology of reheating steam temperature and secondary reheating, which is applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as failure to achieve results, and achieve large lag, good robustness, and principle clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with embodiment further set forth this inventive method.

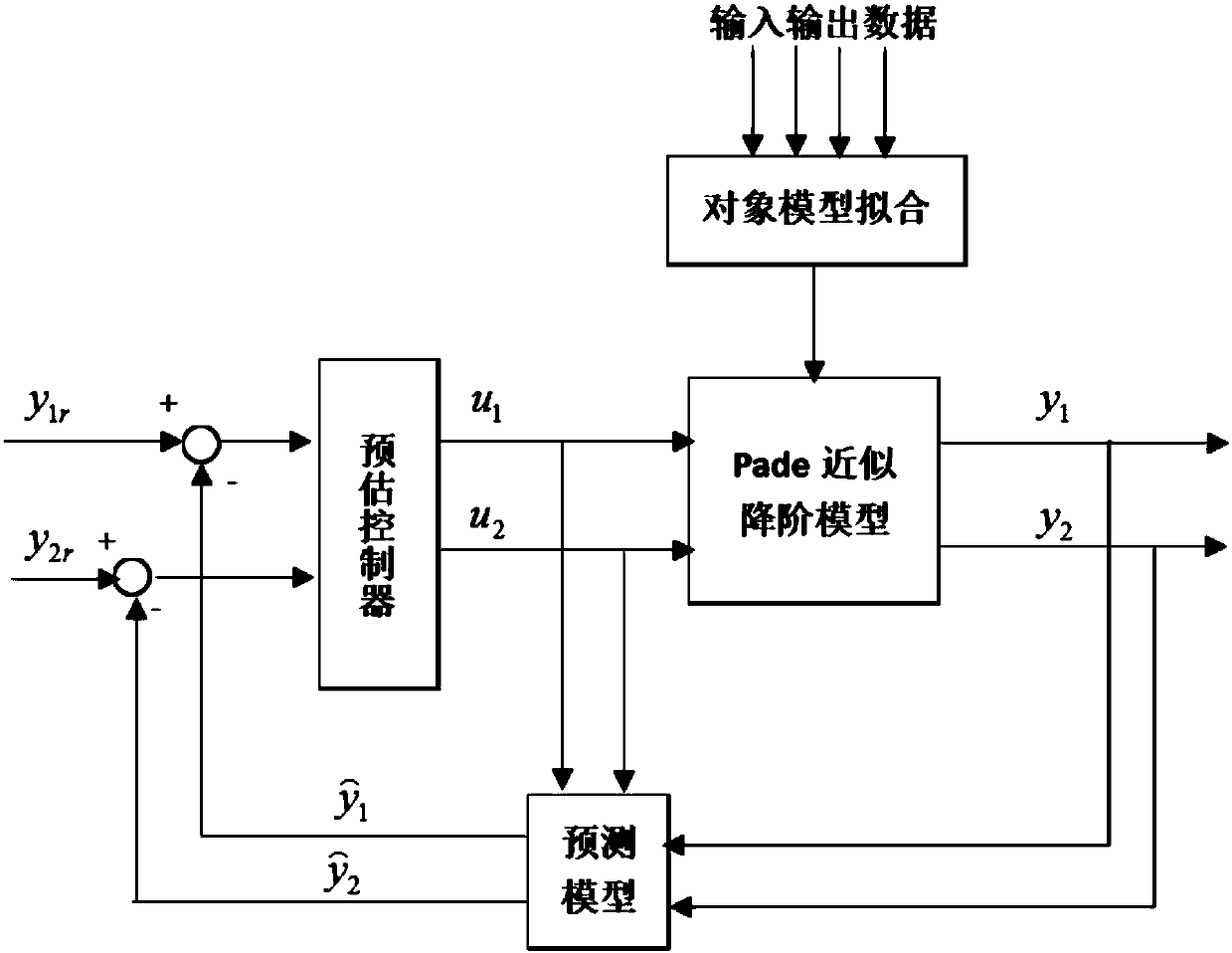

[0066] Such as figure 1 Shown is a schematic diagram of a self-decreasing multi-loop centralized predictive control system for the reheat steam temperature of a double reheat unit. The reheat steam temperature control system includes the flue gas recirculation fan speed control loop and the opening of the flue gas baffle Control loop, the input of the reheat steam temperature control system is the flue gas recirculation fan speed and the opening of the flue gas baffle, and its output is the primary reheat steam temperature and secondary reheat steam temperature. There is coupling, and the object has a large inertia, and a predictive control algorithm that can be reduced is used. figure 1 Middle: The input data are the speed of the flue gas recirculation fan and the opening of the flue gas baffle; the output data are the primary reheat steam temperature and the secondary reheat steam tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com